Resilient supply chains prioritize flexibility, risk management, and rapid recovery from disruptions, contrasting with traditional supply chains that focus primarily on cost efficiency and linear processes. This approach integrates advanced technologies, diversified sourcing, and real-time data analytics to anticipate and mitigate potential threats, enhancing overall economic stability. Explore how resilient supply chains are transforming global trade and strengthening economies worldwide.

Why it is important

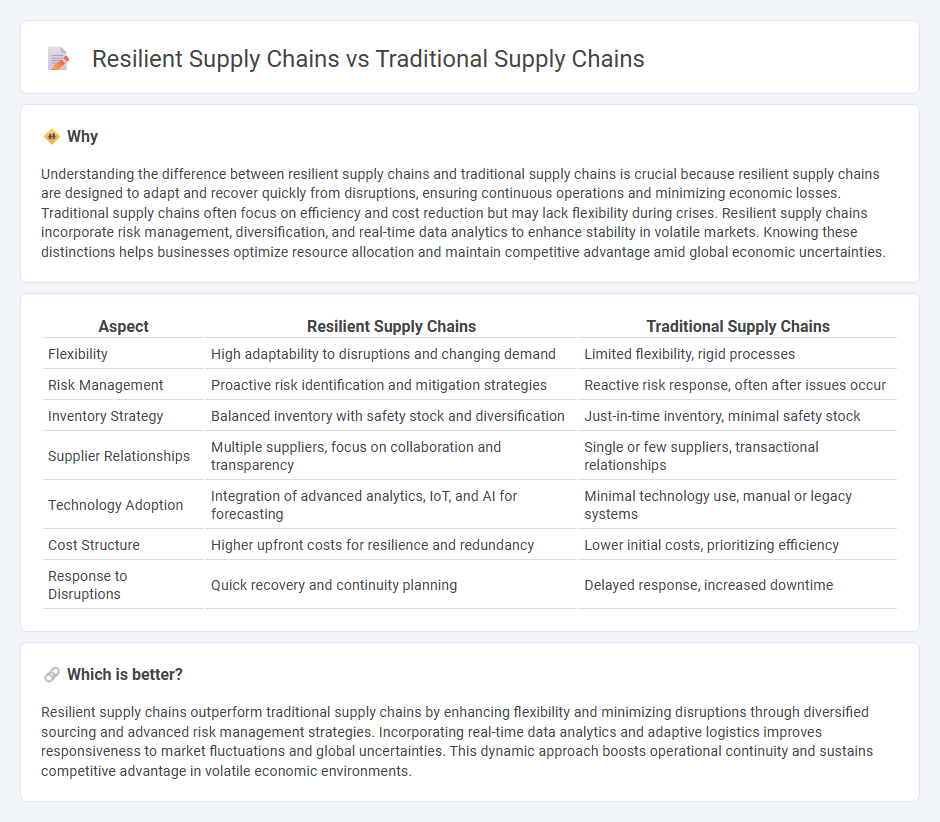

Understanding the difference between resilient supply chains and traditional supply chains is crucial because resilient supply chains are designed to adapt and recover quickly from disruptions, ensuring continuous operations and minimizing economic losses. Traditional supply chains often focus on efficiency and cost reduction but may lack flexibility during crises. Resilient supply chains incorporate risk management, diversification, and real-time data analytics to enhance stability in volatile markets. Knowing these distinctions helps businesses optimize resource allocation and maintain competitive advantage amid global economic uncertainties.

Comparison Table

| Aspect | Resilient Supply Chains | Traditional Supply Chains |

|---|---|---|

| Flexibility | High adaptability to disruptions and changing demand | Limited flexibility, rigid processes |

| Risk Management | Proactive risk identification and mitigation strategies | Reactive risk response, often after issues occur |

| Inventory Strategy | Balanced inventory with safety stock and diversification | Just-in-time inventory, minimal safety stock |

| Supplier Relationships | Multiple suppliers, focus on collaboration and transparency | Single or few suppliers, transactional relationships |

| Technology Adoption | Integration of advanced analytics, IoT, and AI for forecasting | Minimal technology use, manual or legacy systems |

| Cost Structure | Higher upfront costs for resilience and redundancy | Lower initial costs, prioritizing efficiency |

| Response to Disruptions | Quick recovery and continuity planning | Delayed response, increased downtime |

Which is better?

Resilient supply chains outperform traditional supply chains by enhancing flexibility and minimizing disruptions through diversified sourcing and advanced risk management strategies. Incorporating real-time data analytics and adaptive logistics improves responsiveness to market fluctuations and global uncertainties. This dynamic approach boosts operational continuity and sustains competitive advantage in volatile economic environments.

Connection

Resilient supply chains enhance traditional supply chains by integrating risk management strategies, advanced technologies, and diversified sourcing to withstand disruptions. This connection ensures continuous production flow and faster recovery from events such as natural disasters, pandemics, or geopolitical tensions. Strengthening traditional supply chains with resilience measures optimizes business continuity and reduces vulnerability in global trade networks.

Key Terms

Efficiency vs. Flexibility

Traditional supply chains prioritize efficiency through cost reduction and streamlined processes, emphasizing just-in-time inventory and centralized control. Resilient supply chains focus on flexibility, incorporating redundancy, diverse sourcing, and rapid adaptability to disruptions. Explore further to understand how shifting from efficiency to flexibility impacts supply chain performance and risk management.

Just-in-Time vs. Buffer Inventory

Traditional supply chains emphasize Just-in-Time (JIT) inventory management to minimize holding costs and increase efficiency by receiving goods only as needed. Resilient supply chains prioritize buffer inventory to absorb disruptions and maintain continuous operations despite demand variability or supply delays. Explore detailed strategies and benefits of both models to optimize your supply chain performance.

Cost Minimization vs. Risk Management

Traditional supply chains emphasize cost minimization through lean inventory and just-in-time processes, often sacrificing flexibility and risk preparedness. Resilient supply chains prioritize risk management by integrating redundancy, diversification of suppliers, and agile response mechanisms to withstand disruptions. Discover how shifting from cost-driven models to resilience-centric strategies can enhance supply chain robustness and long-term efficiency.

Source and External Links

Traditional Supply Chain vs. Digital Supply Chain - Traditional supply chains are reactive, largely static, operate on historical transaction rules, rely on standalone systems with little data-sharing, and focus on linear processes from raw material procurement to customer consumption with limited real-time visibility and agility, leading to slower decision-making and higher costs.

Traditional Supply Chain Management - Traditional supply chain management involves designing, planning, implementing, and controlling supply chain activities to achieve net value and competitive infrastructure by coordinating supply and demand across partners, mainly focusing on production processes with mostly manual problem-solving.

Supply Chain Models: The Comprehensive Guide | NU - Traditional supply chains use models like efficient, responsive, continuous flow, and agile, where the efficient model emphasizes cost reduction and high efficiency suitable for stable demand industries, reflecting common traditional practices like cost focus and bulk purchasing.

dowidth.com

dowidth.com