Slowbalization represents a gradual deceleration in global economic integration, characterized by reduced cross-border trade and investment flows compared to previous decades. Reshoring involves companies relocating manufacturing and supply chains back to their home countries to enhance control, reduce risks, and respond to geopolitical tensions. Explore how these contrasting trends are reshaping the global economy and influencing business strategies worldwide.

Why it is important

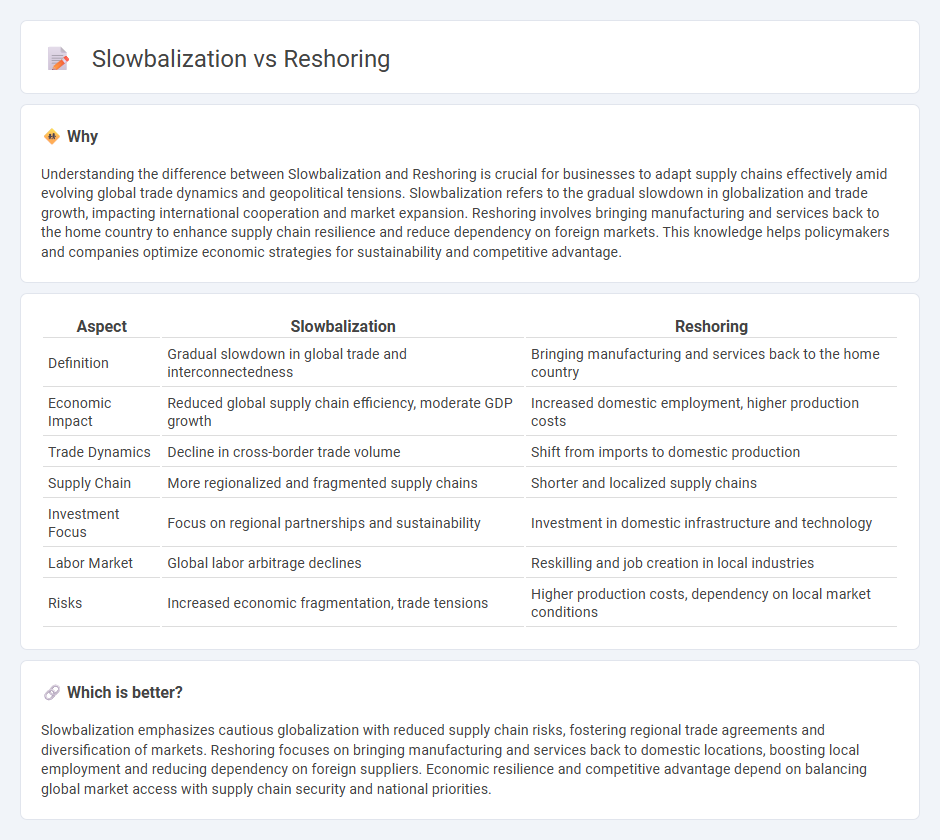

Understanding the difference between Slowbalization and Reshoring is crucial for businesses to adapt supply chains effectively amid evolving global trade dynamics and geopolitical tensions. Slowbalization refers to the gradual slowdown in globalization and trade growth, impacting international cooperation and market expansion. Reshoring involves bringing manufacturing and services back to the home country to enhance supply chain resilience and reduce dependency on foreign markets. This knowledge helps policymakers and companies optimize economic strategies for sustainability and competitive advantage.

Comparison Table

| Aspect | Slowbalization | Reshoring |

|---|---|---|

| Definition | Gradual slowdown in global trade and interconnectedness | Bringing manufacturing and services back to the home country |

| Economic Impact | Reduced global supply chain efficiency, moderate GDP growth | Increased domestic employment, higher production costs |

| Trade Dynamics | Decline in cross-border trade volume | Shift from imports to domestic production |

| Supply Chain | More regionalized and fragmented supply chains | Shorter and localized supply chains |

| Investment Focus | Focus on regional partnerships and sustainability | Investment in domestic infrastructure and technology |

| Labor Market | Global labor arbitrage declines | Reskilling and job creation in local industries |

| Risks | Increased economic fragmentation, trade tensions | Higher production costs, dependency on local market conditions |

Which is better?

Slowbalization emphasizes cautious globalization with reduced supply chain risks, fostering regional trade agreements and diversification of markets. Reshoring focuses on bringing manufacturing and services back to domestic locations, boosting local employment and reducing dependency on foreign suppliers. Economic resilience and competitive advantage depend on balancing global market access with supply chain security and national priorities.

Connection

Slowbalization, characterized by the deceleration of global trade and investment growth, drives companies to pursue reshoring to reduce supply chain vulnerabilities and increase local production resilience. Reshoring supports economic stability by creating domestic jobs and minimizing dependency on distant suppliers amid geopolitical tensions. Both phenomena highlight a strategic shift towards regionalization and supply chain diversification to enhance economic security.

Key Terms

Supply Chain

Reshoring involves bringing manufacturing and supply chain operations back to a company's home country to reduce dependency on global networks and enhance control over production quality and timing. Slowbalization reflects a trend toward reduced globalization intensity, characterized by regional supply chains and strategic diversification to mitigate risks and increase resilience amid geopolitical tensions. Explore the impact of reshoring and slowbalization on supply chain strategies and global trade dynamics to understand future operational shifts.

Trade Policy

Trade policies increasingly favor reshoring as nations aim to reduce dependency on complex global supply chains and enhance domestic manufacturing capabilities. Slowbalization, characterized by a gradual slowdown in globalization, reflects strategic adjustments to tariffs, export controls, and trade agreements that prioritize national security and economic resilience. Explore how evolving trade policies reshape the balance between global integration and supply chain localization.

Manufacturing Relocation

Reshoring involves bringing manufacturing operations back to a company's home country to reduce supply chain vulnerabilities and increase control over production quality. Slowbalization reflects a trend of moderated globalization, where firms diversify manufacturing locations but favor regional rather than global networks to balance risk and cost efficiency. Explore further to understand how reshoring and slowbalization reshape global manufacturing strategies.

Source and External Links

Reshoring - SCRG - Reshoring is the process of bringing manufacturing operations back from a foreign country to a business's home country, aimed at regaining control over quality, lead time, intellectual property, and supply chain visibility while reducing risks associated with foreign production.

What is Reshoring? - Reshoring involves bringing manufacturing and services back to the US from overseas to strengthen the economy by creating jobs, balancing trade deficits, and improving cost and innovation efficiency for companies.

Offshoring vs reshoring - The Rodon Group - Reshoring offers benefits like job creation, lower delivery costs, shorter lead times, higher product quality, better customer perception, and a smaller environmental impact by relocating manufacturing back to the company's home country.

dowidth.com

dowidth.com