Onshoring and backshoring focus on relocating production processes closer to a company's home country to reduce costs, improve supply chain resilience, and enhance quality control. These strategic moves address global economic challenges such as rising labor costs abroad and disruptions caused by geopolitical tensions. Explore the benefits and risks associated with onshoring and backshoring to understand their impact on modern economic landscapes.

Why it is important

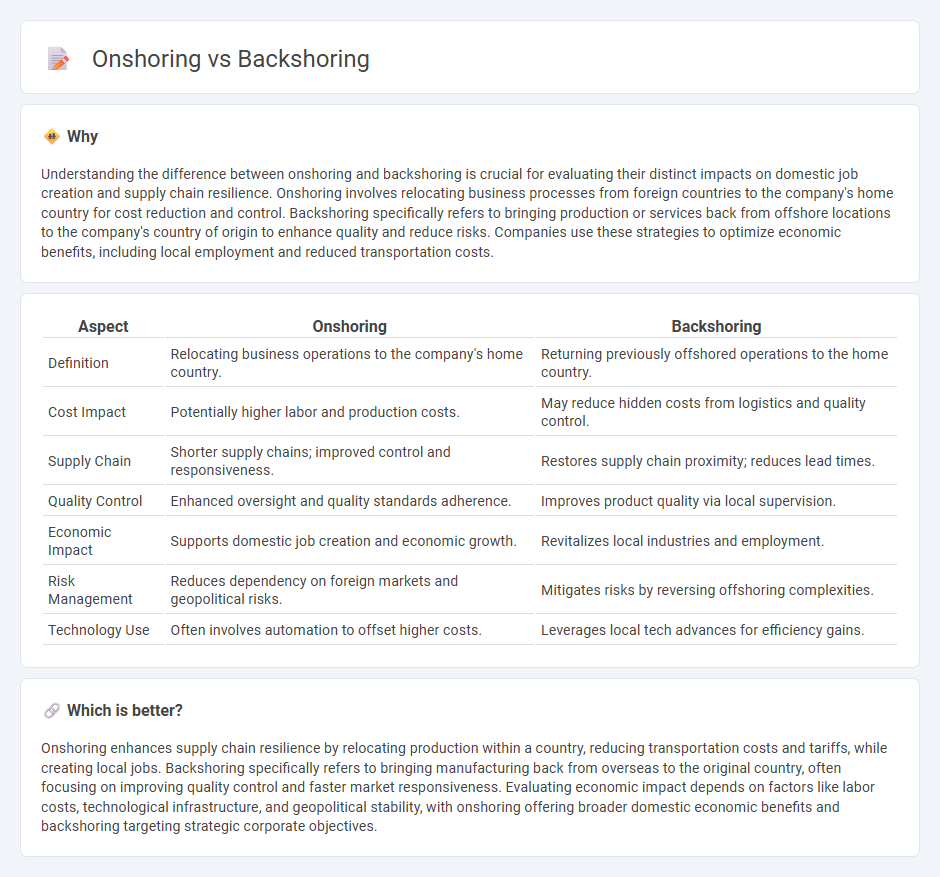

Understanding the difference between onshoring and backshoring is crucial for evaluating their distinct impacts on domestic job creation and supply chain resilience. Onshoring involves relocating business processes from foreign countries to the company's home country for cost reduction and control. Backshoring specifically refers to bringing production or services back from offshore locations to the company's country of origin to enhance quality and reduce risks. Companies use these strategies to optimize economic benefits, including local employment and reduced transportation costs.

Comparison Table

| Aspect | Onshoring | Backshoring |

|---|---|---|

| Definition | Relocating business operations to the company's home country. | Returning previously offshored operations to the home country. |

| Cost Impact | Potentially higher labor and production costs. | May reduce hidden costs from logistics and quality control. |

| Supply Chain | Shorter supply chains; improved control and responsiveness. | Restores supply chain proximity; reduces lead times. |

| Quality Control | Enhanced oversight and quality standards adherence. | Improves product quality via local supervision. |

| Economic Impact | Supports domestic job creation and economic growth. | Revitalizes local industries and employment. |

| Risk Management | Reduces dependency on foreign markets and geopolitical risks. | Mitigates risks by reversing offshoring complexities. |

| Technology Use | Often involves automation to offset higher costs. | Leverages local tech advances for efficiency gains. |

Which is better?

Onshoring enhances supply chain resilience by relocating production within a country, reducing transportation costs and tariffs, while creating local jobs. Backshoring specifically refers to bringing manufacturing back from overseas to the original country, often focusing on improving quality control and faster market responsiveness. Evaluating economic impact depends on factors like labor costs, technological infrastructure, and geopolitical stability, with onshoring offering broader domestic economic benefits and backshoring targeting strategic corporate objectives.

Connection

Onshoring and backshoring both involve relocating production or services closer to a company's home country to enhance control over supply chains and reduce transportation costs. These strategies mitigate risks associated with global disruptions, such as tariffs or political instability, by fostering domestic manufacturing capabilities. Businesses adopt onshoring and backshoring to leverage local labor markets, improve quality standards, and boost economic growth within their home economy.

Key Terms

Supply Chain

Backshoring brings manufacturing closer to home by relocating production facilities from overseas to the company's original country, enhancing supply chain responsiveness and reducing lead times. Onshoring refers to producing goods domestically from the outset, ensuring greater control over quality, compliance, and logistics within the supply chain. Explore detailed insights on how backshoring and onshoring strategies optimize supply chain efficiency and resilience.

Cost Structure

Backshoring often reduces long-term operational costs by eliminating overseas shipping fees, tariffs, and currency exchange risks, improving supply chain reliability. Onshoring emphasizes leveraging local labor markets and infrastructure, potentially increasing upfront expenses but benefiting from closer oversight and faster turnaround times. Explore detailed cost analysis and strategic considerations to determine the optimal approach for your business.

Domestic Production

Backshoring involves relocating manufacturing or services from overseas back to the company's home country to boost domestic production and reduce supply chain risks. Onshoring refers to shifting operations to local facilities within the same country, enhancing control over production quality and lead times. Explore the advantages and economic impacts of backshoring and onshoring techniques to optimize your domestic production strategy.

Source and External Links

Nearshoring Vs. Reshoring Vs. Backshoring: What Are They? - Backshoring is a form of reshoring that involves bringing production back entirely in-house, meaning the company not only returns production to its home country but also internalizes all manufacturing functions instead of outsourcing them.

Backshoring and nearshoring: An overview - Wiley Online Library - Backshoring is part of a trend where developed economies relocate manufacturing activities back home, driven by the loss of strategic advantages in traditional offshoring locations.

Backshoring vs. reshoring in drop head slab formwork systems - In construction, backshoring refers to a system where temporary post shores support a concrete slab to prevent deflection, distinct from business backshoring but sharing the terminology.

dowidth.com

dowidth.com