Liquid cooling systems use specialized fluids to efficiently transfer heat away from high-performance electronics, enhancing device reliability and performance. Ice bath cooling leverages subzero temperature immersion to rapidly dissipate heat, commonly applied in athletic recovery and experimental settings. Explore the advantages and applications of both cooling methods to understand their impact on technology and performance.

Why it is important

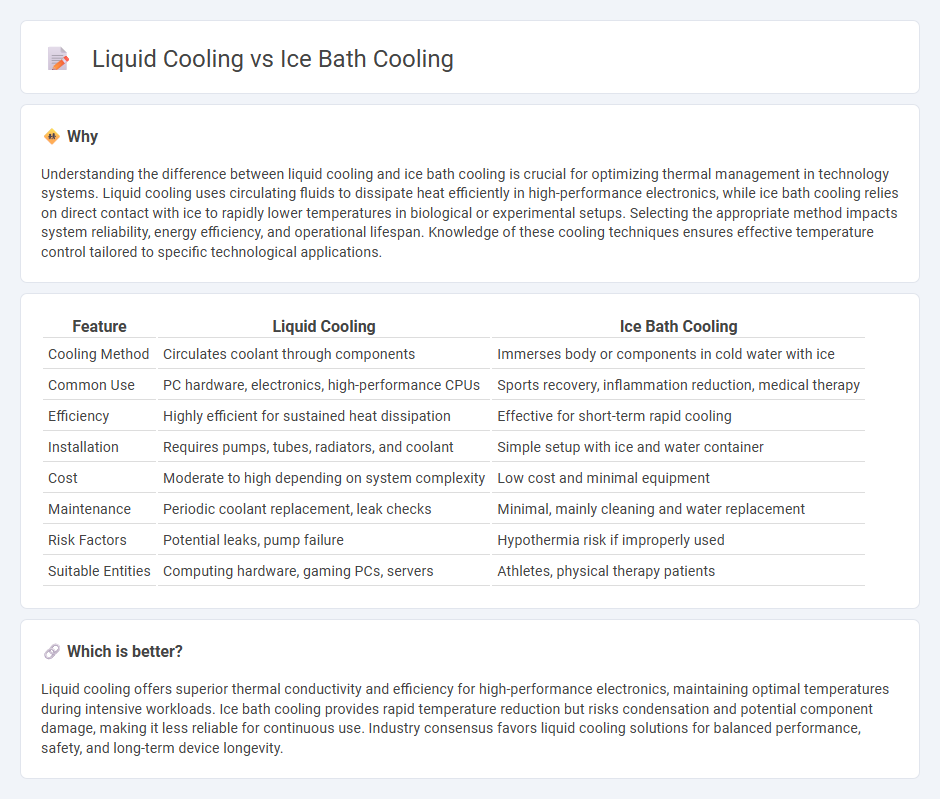

Understanding the difference between liquid cooling and ice bath cooling is crucial for optimizing thermal management in technology systems. Liquid cooling uses circulating fluids to dissipate heat efficiently in high-performance electronics, while ice bath cooling relies on direct contact with ice to rapidly lower temperatures in biological or experimental setups. Selecting the appropriate method impacts system reliability, energy efficiency, and operational lifespan. Knowledge of these cooling techniques ensures effective temperature control tailored to specific technological applications.

Comparison Table

| Feature | Liquid Cooling | Ice Bath Cooling |

|---|---|---|

| Cooling Method | Circulates coolant through components | Immerses body or components in cold water with ice |

| Common Use | PC hardware, electronics, high-performance CPUs | Sports recovery, inflammation reduction, medical therapy |

| Efficiency | Highly efficient for sustained heat dissipation | Effective for short-term rapid cooling |

| Installation | Requires pumps, tubes, radiators, and coolant | Simple setup with ice and water container |

| Cost | Moderate to high depending on system complexity | Low cost and minimal equipment |

| Maintenance | Periodic coolant replacement, leak checks | Minimal, mainly cleaning and water replacement |

| Risk Factors | Potential leaks, pump failure | Hypothermia risk if improperly used |

| Suitable Entities | Computing hardware, gaming PCs, servers | Athletes, physical therapy patients |

Which is better?

Liquid cooling offers superior thermal conductivity and efficiency for high-performance electronics, maintaining optimal temperatures during intensive workloads. Ice bath cooling provides rapid temperature reduction but risks condensation and potential component damage, making it less reliable for continuous use. Industry consensus favors liquid cooling solutions for balanced performance, safety, and long-term device longevity.

Connection

Liquid cooling in technology uses a coolant to absorb and transfer heat from electronic components, enhancing performance and longevity. Ice bath cooling applies a similar principle by using chilled water or ice to lower temperatures rapidly, often in experimental or high-performance computing settings. Both methods rely on efficient heat dissipation to maintain optimal operating conditions and prevent overheating.

Key Terms

Thermal Conductivity

Ice bath cooling leverages the high latent heat of fusion in water ice, allowing efficient thermal energy absorption and rapid temperature reduction due to water's thermal conductivity of approximately 0.6 W/m*K. Liquid cooling systems often use specially designed coolants with higher thermal conductivities, such as glycol mixtures around 0.4 W/m*K, enabling precise heat transfer in electronic and mechanical applications. Explore deeper insights into thermal management technologies to optimize cooling performance.

Heat Exchanger

Ice bath cooling leverages phase change and high thermal capacity of ice to rapidly absorb heat via the heat exchanger, providing efficient temperature control in industrial applications. Liquid cooling systems use pumps to circulate coolant through heat exchangers, enabling continuous heat transfer and precise temperature regulation critical in electronics and high-performance machinery. Explore detailed comparisons of heat exchanger designs and performance metrics to choose the optimal cooling solution for your needs.

Coolant Fluid

Ice bath cooling uses chilled water or ice as the coolant fluid to absorb and dissipate heat through phase change and thermal conduction. Liquid cooling systems often employ specialized coolants such as glycol-water mixtures or dielectric fluids to enhance heat transfer efficiency and prevent corrosion in electronic components. Explore the advantages and applications of different coolant fluids to optimize your cooling solution.

Source and External Links

Tips For How to Keep an Ice Bath Cold - Use large ice blocks, insulate your tub, prepare your bath the night before, and always keep the lid on to maintain a consistently cold ice bath with minimal ice melt.

Best Water Chillers for Ice Bath & Cold Plunge - Water chillers offer a convenient, energy-efficient solution for keeping ice baths at a precise temperature, with remote control options and various horsepower models for different tub sizes--so you never need to add ice manually.

The Pod Chiller - Water Chiller for Ice Bath - This compact, affordable chiller cools water to 41degF (5degC), operates quietly and efficiently, and is designed for both indoor and outdoor use, eliminating the need for repeated ice purchases.

dowidth.com

dowidth.com