Quantum sensing harnesses quantum phenomena such as superposition and entanglement to achieve unparalleled sensitivity and precision in detecting physical quantities, outperforming conventional sensors. MEMS sensing employs microelectromechanical systems to measure parameters like acceleration, pressure, and temperature with compact size and low power consumption, making it ideal for consumer electronics and industrial applications. Explore the distinctions and advancements of quantum sensing versus MEMS sensing to understand their transformative impact on technology.

Why it is important

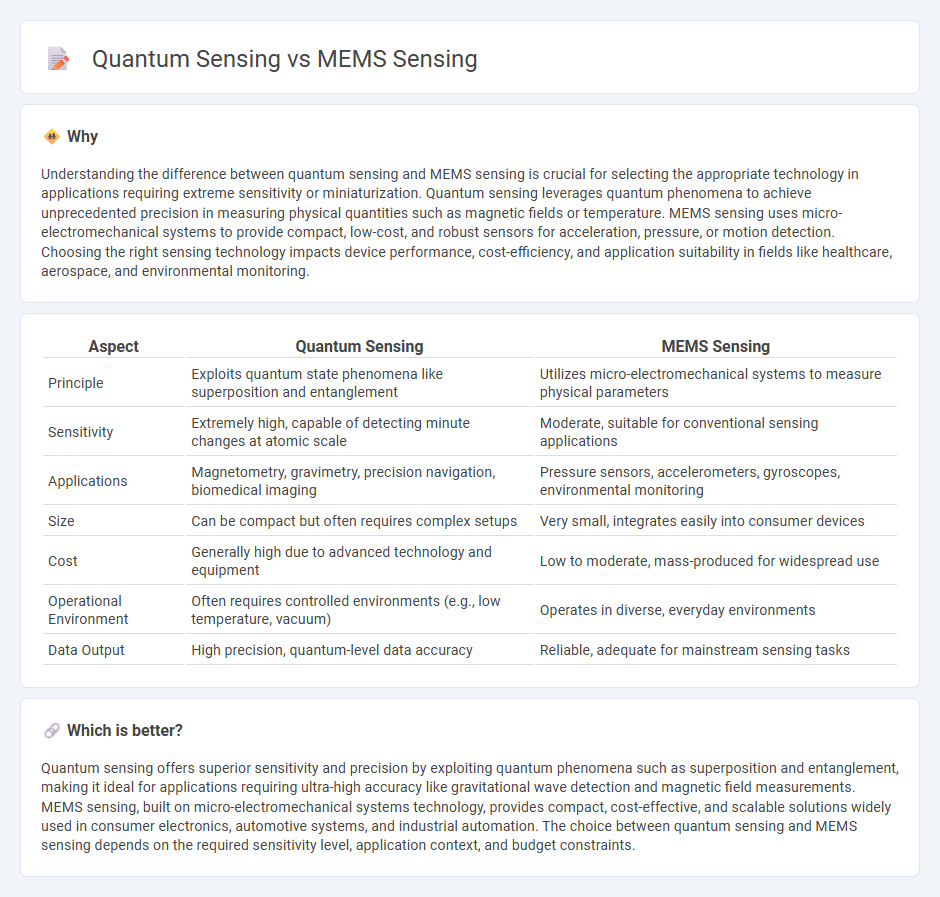

Understanding the difference between quantum sensing and MEMS sensing is crucial for selecting the appropriate technology in applications requiring extreme sensitivity or miniaturization. Quantum sensing leverages quantum phenomena to achieve unprecedented precision in measuring physical quantities such as magnetic fields or temperature. MEMS sensing uses micro-electromechanical systems to provide compact, low-cost, and robust sensors for acceleration, pressure, or motion detection. Choosing the right sensing technology impacts device performance, cost-efficiency, and application suitability in fields like healthcare, aerospace, and environmental monitoring.

Comparison Table

| Aspect | Quantum Sensing | MEMS Sensing |

|---|---|---|

| Principle | Exploits quantum state phenomena like superposition and entanglement | Utilizes micro-electromechanical systems to measure physical parameters |

| Sensitivity | Extremely high, capable of detecting minute changes at atomic scale | Moderate, suitable for conventional sensing applications |

| Applications | Magnetometry, gravimetry, precision navigation, biomedical imaging | Pressure sensors, accelerometers, gyroscopes, environmental monitoring |

| Size | Can be compact but often requires complex setups | Very small, integrates easily into consumer devices |

| Cost | Generally high due to advanced technology and equipment | Low to moderate, mass-produced for widespread use |

| Operational Environment | Often requires controlled environments (e.g., low temperature, vacuum) | Operates in diverse, everyday environments |

| Data Output | High precision, quantum-level data accuracy | Reliable, adequate for mainstream sensing tasks |

Which is better?

Quantum sensing offers superior sensitivity and precision by exploiting quantum phenomena such as superposition and entanglement, making it ideal for applications requiring ultra-high accuracy like gravitational wave detection and magnetic field measurements. MEMS sensing, built on micro-electromechanical systems technology, provides compact, cost-effective, and scalable solutions widely used in consumer electronics, automotive systems, and industrial automation. The choice between quantum sensing and MEMS sensing depends on the required sensitivity level, application context, and budget constraints.

Connection

Quantum sensing and MEMS sensing are connected through their shared goal of enhancing measurement precision by exploiting unique physical properties at micro and nanoscale levels. Quantum sensors utilize principles such as superposition and entanglement to detect minute changes in physical quantities, while MEMS sensors rely on microscale mechanical components to measure variables like acceleration and pressure with high sensitivity. Integrating quantum sensing techniques with MEMS technology enables the development of compact, ultra-sensitive devices capable of unprecedented accuracy in applications ranging from medical diagnostics to navigation systems.

Key Terms

Miniaturization

MEMS sensing leverages microfabrication to create compact, low-power sensors ideal for widespread applications, while quantum sensing exploits quantum states to achieve exceptional precision at nanoscale dimensions. Both technologies prioritize miniaturization but differ in operational principles--MEMS utilizes mechanical components, whereas quantum sensors rely on quantum phenomena such as superposition and entanglement. Explore further to understand how miniaturization drives innovation in sensor technologies.

Sensitivity

MEMS sensing technology enables detecting physical parameters with micro-scale mechanical components, offering moderate sensitivity suitable for various industrial applications. Quantum sensing utilizes quantum phenomena such as superposition and entanglement to achieve ultra-high sensitivity, surpassing classical limits in detecting magnetic fields, temperature, and acceleration. Explore the advancements in these sensing technologies to understand their impact on precision measurement and emerging technologies.

Measurement Principle

MEMS sensing utilizes micro-scale mechanical elements that detect physical changes through variations in capacitance, piezoresistivity, or resonance frequency shifts, enabling precise measurements of acceleration, pressure, and strain. Quantum sensing exploits phenomena like superposition and entanglement within quantum systems to achieve ultra-high sensitivity and accuracy in detecting magnetic fields, temperature, or gravitational forces. Explore the fundamental differences in these measurement principles to understand their distinct applications and advantages.

Source and External Links

MEMS sensors | Bosch Sensortec - MEMS sensors are tiny microelectromechanical systems that detect mechanical, magnetic, or chemical changes and convert them into electrical signals, enabling functions like motion detection, pressure, temperature, and gas sensing with high accuracy and low power consumption in consumer electronics.

How Does a MEMS Sensor Work? - Jewell Instruments - MEMS sensors operate by having a suspended mass between capacitive plates; changes in tilt cause changes in capacitance, which correspond to differential electrical signals used for precise sensing in industrial and aerospace applications.

A Comprehensive guide to MEMS sensors - ES Systems - MEMS sensors detect changes in resistance or capacitance caused by physical forces, converting these variations into electrical signals for accurate measurement of pressure, motion, gas, or sound, widely used in industrial, automotive, and environmental monitoring.

dowidth.com

dowidth.com