Modular home construction involves building fully assembled sections in a factory before transporting them to the site, ensuring speed and quality control. Panelized home construction uses pre-cut wall panels shipped to the location for on-site assembly, offering design flexibility and reduced construction time. Discover detailed comparisons to determine which method suits your real estate investment needs.

Why it is important

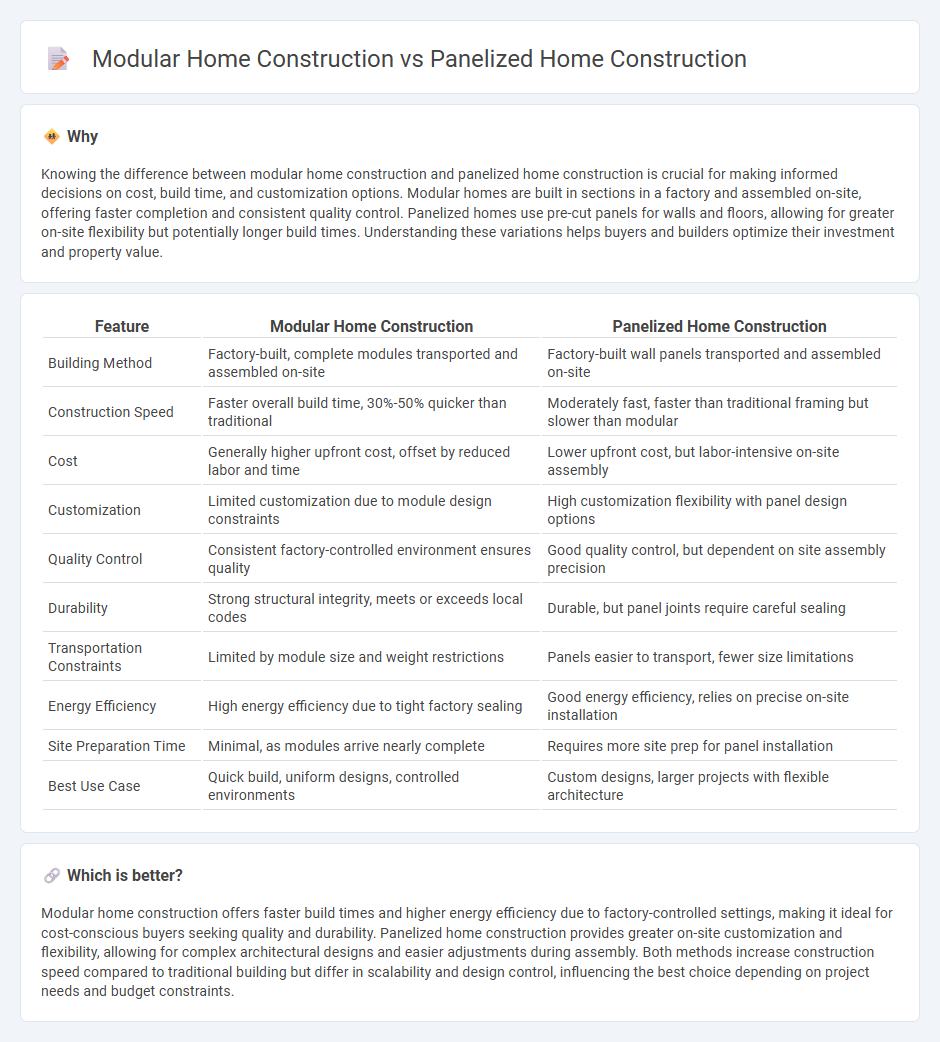

Knowing the difference between modular home construction and panelized home construction is crucial for making informed decisions on cost, build time, and customization options. Modular homes are built in sections in a factory and assembled on-site, offering faster completion and consistent quality control. Panelized homes use pre-cut panels for walls and floors, allowing for greater on-site flexibility but potentially longer build times. Understanding these variations helps buyers and builders optimize their investment and property value.

Comparison Table

| Feature | Modular Home Construction | Panelized Home Construction |

|---|---|---|

| Building Method | Factory-built, complete modules transported and assembled on-site | Factory-built wall panels transported and assembled on-site |

| Construction Speed | Faster overall build time, 30%-50% quicker than traditional | Moderately fast, faster than traditional framing but slower than modular |

| Cost | Generally higher upfront cost, offset by reduced labor and time | Lower upfront cost, but labor-intensive on-site assembly |

| Customization | Limited customization due to module design constraints | High customization flexibility with panel design options |

| Quality Control | Consistent factory-controlled environment ensures quality | Good quality control, but dependent on site assembly precision |

| Durability | Strong structural integrity, meets or exceeds local codes | Durable, but panel joints require careful sealing |

| Transportation Constraints | Limited by module size and weight restrictions | Panels easier to transport, fewer size limitations |

| Energy Efficiency | High energy efficiency due to tight factory sealing | Good energy efficiency, relies on precise on-site installation |

| Site Preparation Time | Minimal, as modules arrive nearly complete | Requires more site prep for panel installation |

| Best Use Case | Quick build, uniform designs, controlled environments | Custom designs, larger projects with flexible architecture |

Which is better?

Modular home construction offers faster build times and higher energy efficiency due to factory-controlled settings, making it ideal for cost-conscious buyers seeking quality and durability. Panelized home construction provides greater on-site customization and flexibility, allowing for complex architectural designs and easier adjustments during assembly. Both methods increase construction speed compared to traditional building but differ in scalability and design control, influencing the best choice depending on project needs and budget constraints.

Connection

Modular home construction and panelized home construction both utilize prefabricated components to streamline building processes and reduce onsite labor costs. Modular homes are built in sections or modules within a factory setting, while panelized homes use pre-cut panels for walls, floors, and roofs, allowing faster assembly and improved quality control. Both methods enhance construction efficiency, minimize waste, and offer customizable design options tailored to various real estate developments.

Key Terms

Prefabrication

Panelized home construction uses factory-built wall panels, floors, and roof sections shipped to the site for quick assembly, improving efficiency and reducing onsite labor. Modular home construction involves building entire sections or modules in a factory, which are then transported and assembled onsite, offering higher consistency and faster build times. Explore the details of both prefabrication methods to determine which suits your construction needs best.

On-site Assembly

Panelized home construction involves building wall panels, floors, and roof sections in a factory and then transporting them to the site for assembly, significantly reducing on-site labor and time. Modular home construction, however, delivers fully finished modules or sections that are craned into place and require minimal on-site assembly, leading to faster project completion and less weather-related delays. Explore the detailed differences in on-site assembly processes to determine the best construction method for your project.

Building Codes

Panelized home construction adheres strictly to local building codes by producing pre-cut wall panels in a factory that comply with regional standards before on-site assembly, ensuring structural integrity and energy efficiency. Modular home construction involves building entire sections or modules off-site, which must meet the same rigorous local and national building codes as site-built homes, including fire safety, plumbing, and electrical regulations. Explore the specifics of building code requirements and compliance processes to choose the best option for your construction project.

Source and External Links

Panelized Construction - Momo Homes - This webpage explains the process and benefits of panelized home construction, including pre-construction planning, manufacturing in a controlled environment, and on-site assembly.

Panelized Homes: Your Questions Answered - Yankee Barn Homes - This article provides an overview of panelized homes, highlighting better quality and cost-effectiveness compared to traditional stick framing, with features like factory-installed windows.

Overview of Panelized Construction - GreenBuildingAdvisor - This webpage offers an overview of panelized construction, detailing the process of factory-built walls, floors, and roofs being transported to the construction site for assembly.

dowidth.com

dowidth.com