Modular home construction involves building sections of a home in a factory setting, which are then transported and assembled on-site, ensuring higher quality control and customization options. Manufactured homes are built entirely in factories under federal HUD standards, offering cost-effective and quicker alternatives but often with more limitations on design and durability. Explore the key differences to determine the best choice for your housing needs.

Why it is important

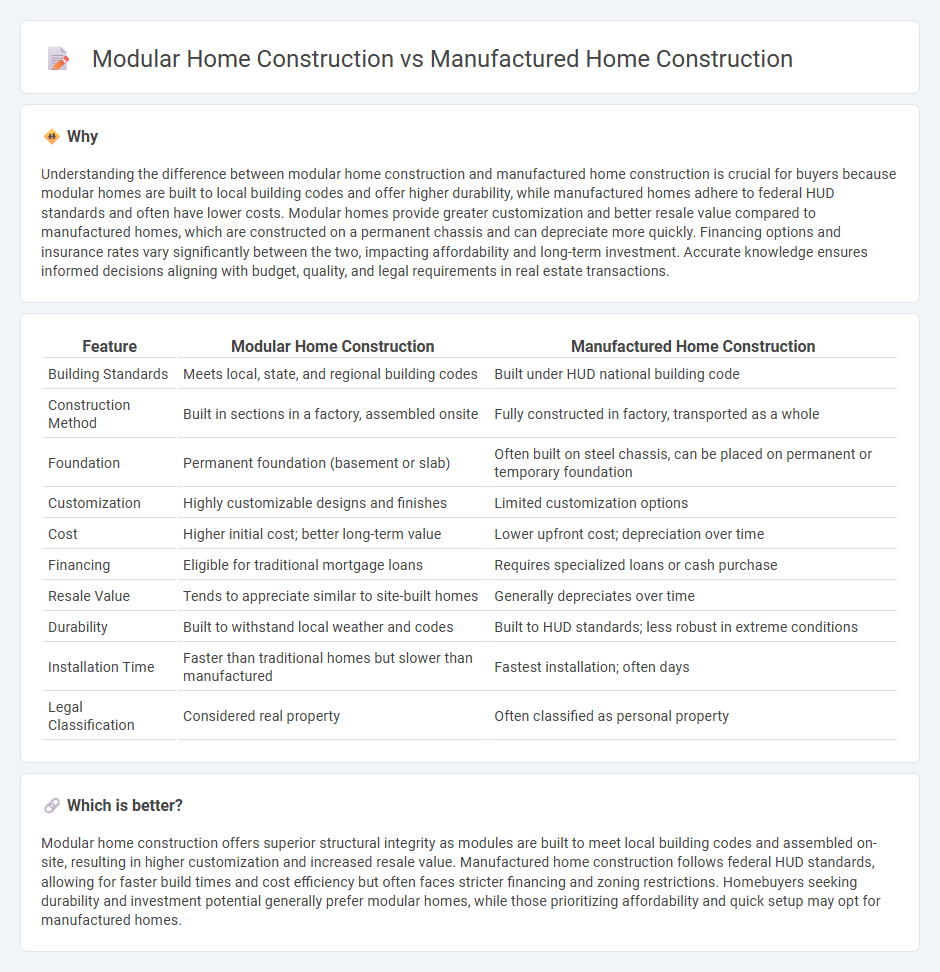

Understanding the difference between modular home construction and manufactured home construction is crucial for buyers because modular homes are built to local building codes and offer higher durability, while manufactured homes adhere to federal HUD standards and often have lower costs. Modular homes provide greater customization and better resale value compared to manufactured homes, which are constructed on a permanent chassis and can depreciate more quickly. Financing options and insurance rates vary significantly between the two, impacting affordability and long-term investment. Accurate knowledge ensures informed decisions aligning with budget, quality, and legal requirements in real estate transactions.

Comparison Table

| Feature | Modular Home Construction | Manufactured Home Construction |

|---|---|---|

| Building Standards | Meets local, state, and regional building codes | Built under HUD national building code |

| Construction Method | Built in sections in a factory, assembled onsite | Fully constructed in factory, transported as a whole |

| Foundation | Permanent foundation (basement or slab) | Often built on steel chassis, can be placed on permanent or temporary foundation |

| Customization | Highly customizable designs and finishes | Limited customization options |

| Cost | Higher initial cost; better long-term value | Lower upfront cost; depreciation over time |

| Financing | Eligible for traditional mortgage loans | Requires specialized loans or cash purchase |

| Resale Value | Tends to appreciate similar to site-built homes | Generally depreciates over time |

| Durability | Built to withstand local weather and codes | Built to HUD standards; less robust in extreme conditions |

| Installation Time | Faster than traditional homes but slower than manufactured | Fastest installation; often days |

| Legal Classification | Considered real property | Often classified as personal property |

Which is better?

Modular home construction offers superior structural integrity as modules are built to meet local building codes and assembled on-site, resulting in higher customization and increased resale value. Manufactured home construction follows federal HUD standards, allowing for faster build times and cost efficiency but often faces stricter financing and zoning restrictions. Homebuyers seeking durability and investment potential generally prefer modular homes, while those prioritizing affordability and quick setup may opt for manufactured homes.

Connection

Modular home construction and manufactured home construction both involve building homes in controlled factory environments, which improves quality control and reduces construction time. Modular homes are built to local building codes and assembled on-site, while manufactured homes adhere to federal HUD standards and are transported as complete units. Both methods offer cost-effective, efficient alternatives to traditional on-site construction, making housing more accessible and flexible.

Key Terms

Building Codes

Manufactured home construction adheres to the HUD Code, ensuring federally regulated standards for safety, durability, and energy efficiency, while modular home construction complies with local and state building codes identical to site-built homes. Manufactured homes are built entirely in factories and transported as complete units, whereas modular homes are constructed in sections and assembled on-site to meet specific regional regulations. Explore in-depth differences to understand which building code framework suits your housing needs best.

On-site Assembly

Manufactured home construction involves building sections entirely within a factory and transporting them to the site for quick on-site assembly, typically designed to meet HUD codes. Modular home construction also occurs off-site but features larger, pre-fabricated modules that are assembled on-site and adhere to local building codes, providing greater flexibility in design. Explore the differences in on-site assembly techniques and construction standards to determine which option suits your housing needs best.

Permanent Foundation

Manufactured home construction involves building homes on a steel chassis, designed for transport and placement without requiring a permanent foundation, often resting on piers or blocks. Modular home construction assembles prefabricated modules in a factory setting, which are then transported and permanently affixed to a foundation onsite, complying with local building codes. Discover more about the structural and regulatory differences ensuring durability and investment security.

Source and External Links

How Manufactured Homes are Built l Clayton Studio - Manufactured homes are built step-by-step in a factory, starting with a steel frame, followed by insulation, flooring, plumbing, wall construction, appliance installation, and finally roofing, all before being transported to their final site.

How are manufactured homes built? | Rocket Mortgage - Manufactured homes are prefabricated structures constructed in a controlled factory environment by skilled workers, then transported to a permanent location, with quality and safety ensured by federal HUD code standards that differ from traditional site-built homes.

About Manufactured Homes - MHI - Today's manufactured homes offer customizable floor plans, quality construction, and amenities comparable to site-built homes, all built to a single federal standard for safety, durability, and energy efficiency, making them a significant source of affordable, unsubsidized housing in the U.S..

dowidth.com

dowidth.com