Cross docking minimizes storage time by directly transferring goods from inbound to outbound transportation, increasing supply chain efficiency. Warehousing involves storing inventory for longer periods, providing flexibility and buffer stock management. Explore the key differences and benefits of cross docking versus warehousing to optimize your logistics strategy.

Why it is important

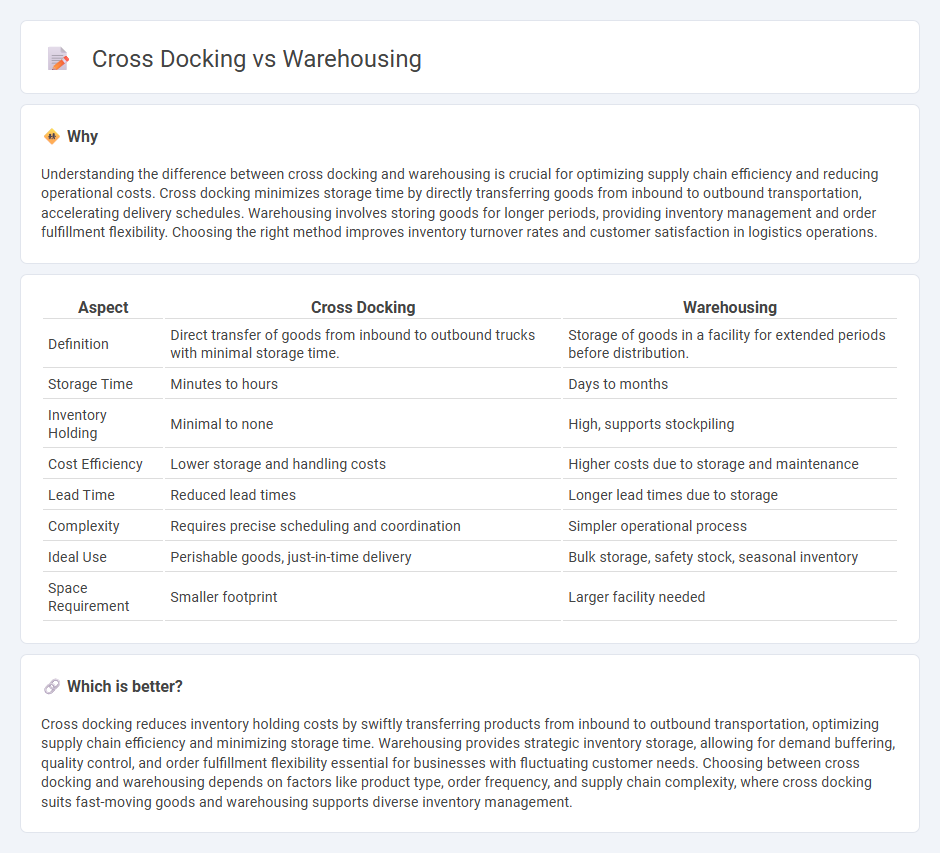

Understanding the difference between cross docking and warehousing is crucial for optimizing supply chain efficiency and reducing operational costs. Cross docking minimizes storage time by directly transferring goods from inbound to outbound transportation, accelerating delivery schedules. Warehousing involves storing goods for longer periods, providing inventory management and order fulfillment flexibility. Choosing the right method improves inventory turnover rates and customer satisfaction in logistics operations.

Comparison Table

| Aspect | Cross Docking | Warehousing |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound trucks with minimal storage time. | Storage of goods in a facility for extended periods before distribution. |

| Storage Time | Minutes to hours | Days to months |

| Inventory Holding | Minimal to none | High, supports stockpiling |

| Cost Efficiency | Lower storage and handling costs | Higher costs due to storage and maintenance |

| Lead Time | Reduced lead times | Longer lead times due to storage |

| Complexity | Requires precise scheduling and coordination | Simpler operational process |

| Ideal Use | Perishable goods, just-in-time delivery | Bulk storage, safety stock, seasonal inventory |

| Space Requirement | Smaller footprint | Larger facility needed |

Which is better?

Cross docking reduces inventory holding costs by swiftly transferring products from inbound to outbound transportation, optimizing supply chain efficiency and minimizing storage time. Warehousing provides strategic inventory storage, allowing for demand buffering, quality control, and order fulfillment flexibility essential for businesses with fluctuating customer needs. Choosing between cross docking and warehousing depends on factors like product type, order frequency, and supply chain complexity, where cross docking suits fast-moving goods and warehousing supports diverse inventory management.

Connection

Cross docking and warehousing are connected through their roles in optimizing supply chain efficiency by minimizing storage time and handling costs. Cross docking relies on strategically located warehouses to facilitate the rapid transfer of goods from inbound to outbound transportation without long-term storage. This integration reduces inventory holding expenses while improving order fulfillment speed and accuracy.

Key Terms

**Warehousing:**

Warehousing involves the storage of goods in a designated facility where inventory is managed, organized, and preserved until distribution. It plays a crucial role in supply chain efficiency by ensuring product availability, inventory accuracy, and protection against damage or theft. Explore more about warehousing strategies, technologies, and benefits to optimize your logistics operations.

Inventory Storage

Warehousing involves storing inventory for extended periods, allowing businesses to manage large stock levels and fulfill orders as needed, which enhances supply chain stability. Cross docking minimizes storage time by directly transferring products from inbound to outbound transportation, reducing inventory holding costs and accelerating delivery times. Explore more about how inventory storage strategies impact logistics efficiency and cost management.

Order Picking

Order picking in warehousing involves selecting individual items from stored inventory, optimizing accuracy and efficiency for direct shipping or assembly. Cross docking minimizes storage by immediately transferring incoming goods to outbound transportation, reducing handling times but limiting extensive order picking. Discover how these strategies impact supply chain operations and order fulfillment.

Source and External Links

What Is Warehousing? Definition, Types, and Key Features - Warehousing is the process of storing goods until they are ready for transport, involving key features like space planning, inventory management, climate control, and efficient product retrieval to optimize supply chain operations.

Warehouse - Wikipedia - A warehouse is a large building used for storing goods and is equipped with loading docks, forklifts, and sometimes automated systems like Warehouse Management Systems (WMS) to improve material handling and inventory accuracy.

Warehousing: Warehousing Functions, Importance, and Benefits - Warehousing functions include setting up warehouse space, receiving and storing goods properly (including temperature-sensitive items), picking, packing, shipping, and monitoring logistics to ensure efficient inventory management and business growth.

dowidth.com

dowidth.com