Robotic Process Automation (RPA) in logistics streamlines repetitive tasks such as order processing, inventory management, and shipment tracking, enhancing operational efficiency and reducing human error. Predictive analytics uses historical data and machine learning algorithms to forecast demand, optimize routing, and improve supply chain decision-making. Explore the advantages and applications of RPA versus predictive analytics to transform your logistics operations.

Why it is important

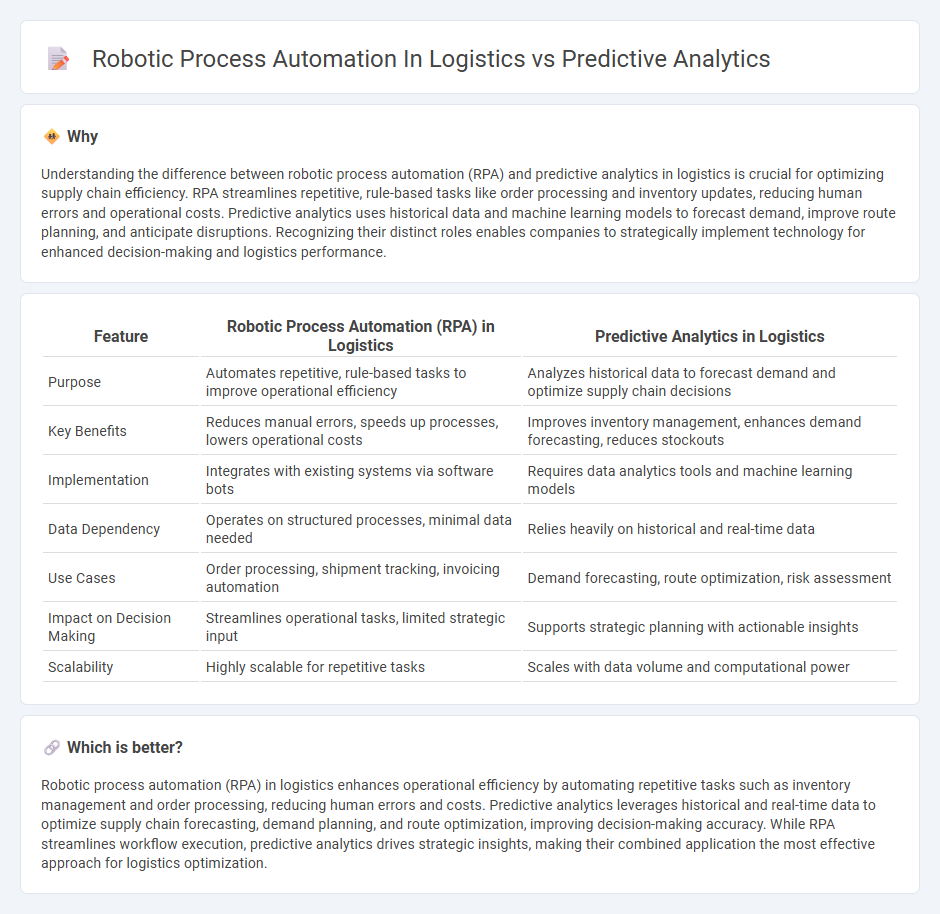

Understanding the difference between robotic process automation (RPA) and predictive analytics in logistics is crucial for optimizing supply chain efficiency. RPA streamlines repetitive, rule-based tasks like order processing and inventory updates, reducing human errors and operational costs. Predictive analytics uses historical data and machine learning models to forecast demand, improve route planning, and anticipate disruptions. Recognizing their distinct roles enables companies to strategically implement technology for enhanced decision-making and logistics performance.

Comparison Table

| Feature | Robotic Process Automation (RPA) in Logistics | Predictive Analytics in Logistics |

|---|---|---|

| Purpose | Automates repetitive, rule-based tasks to improve operational efficiency | Analyzes historical data to forecast demand and optimize supply chain decisions |

| Key Benefits | Reduces manual errors, speeds up processes, lowers operational costs | Improves inventory management, enhances demand forecasting, reduces stockouts |

| Implementation | Integrates with existing systems via software bots | Requires data analytics tools and machine learning models |

| Data Dependency | Operates on structured processes, minimal data needed | Relies heavily on historical and real-time data |

| Use Cases | Order processing, shipment tracking, invoicing automation | Demand forecasting, route optimization, risk assessment |

| Impact on Decision Making | Streamlines operational tasks, limited strategic input | Supports strategic planning with actionable insights |

| Scalability | Highly scalable for repetitive tasks | Scales with data volume and computational power |

Which is better?

Robotic process automation (RPA) in logistics enhances operational efficiency by automating repetitive tasks such as inventory management and order processing, reducing human errors and costs. Predictive analytics leverages historical and real-time data to optimize supply chain forecasting, demand planning, and route optimization, improving decision-making accuracy. While RPA streamlines workflow execution, predictive analytics drives strategic insights, making their combined application the most effective approach for logistics optimization.

Connection

Robotic process automation (RPA) in logistics streamlines repetitive tasks such as inventory management, shipment tracking, and order processing, increasing efficiency and reducing human error. Predictive analytics leverages historical data and machine learning algorithms to forecast demand, optimize routes, and anticipate supply chain disruptions, enabling proactive decision-making. The integration of RPA with predictive analytics enhances real-time responsiveness by automating data-driven actions, thereby improving overall logistics performance and operational agility.

Key Terms

**Predictive Analytics in Logistics:**

Predictive analytics in logistics leverages historical data, machine learning algorithms, and statistical models to forecast demand, optimize inventory levels, and improve route planning, enhancing supply chain efficiency. By analyzing patterns such as delivery times, weather conditions, and shipment statuses, predictive analytics reduces operational costs and mitigates risks like delays or stockouts. Discover how integrating predictive analytics transforms logistics operations for smarter decision-making and competitive advantage.

Demand Forecasting

Demand forecasting in logistics leverages predictive analytics by analyzing historical data and market trends to accurately estimate future product demand, optimizing inventory levels and reducing stockouts. Robotic Process Automation (RPA) enhances logistics efficiency by automating repetitive tasks such as data entry and report generation but relies on predefined rules rather than predictive insights. Explore how integrating predictive analytics and RPA can revolutionize demand forecasting and supply chain management.

Route Optimization

Predictive analytics uses historical data and machine learning algorithms to forecast demand patterns and optimize delivery routes by anticipating traffic conditions and potential delays. Robotic process automation (RPA) streamlines repetitive logistics tasks such as data entry and shipment tracking but lacks the predictive capabilities crucial for dynamic route optimization. Explore more about how predictive analytics enhances logistics efficiency beyond traditional automation techniques.

Source and External Links

What is Predictive Analytics? | IBM - Predictive analytics uses historical data, statistical modeling, machine learning, and data mining to identify patterns and forecast future outcomes, helping companies find risks and opportunities in big data.

What is predictive analytics and how does it work? | Google Cloud - Predictive analytics forecasts future events by using data analysis, machine learning, AI, and statistical models, typically using classification and regression models to predict customer behavior or continuous values.

A Guide To Predictive Analytics | Tableau - Predictive analytics leverages data mining, statistics, AI, and machine learning to analyze historical data for anticipating outcomes, making businesses more proactive by spotting risks and opportunities early.

dowidth.com

dowidth.com