Containerization revolutionizes logistics by standardizing cargo transport, significantly reducing handling costs and transit times compared to traditional methods. Just-in-time (JIT) logistics focuses on minimizing inventory and delivering materials precisely when needed, enhancing efficiency but requiring reliable supply chain coordination. Explore the critical differences and advantages of containerization versus JIT to optimize your logistics strategy.

Why it is important

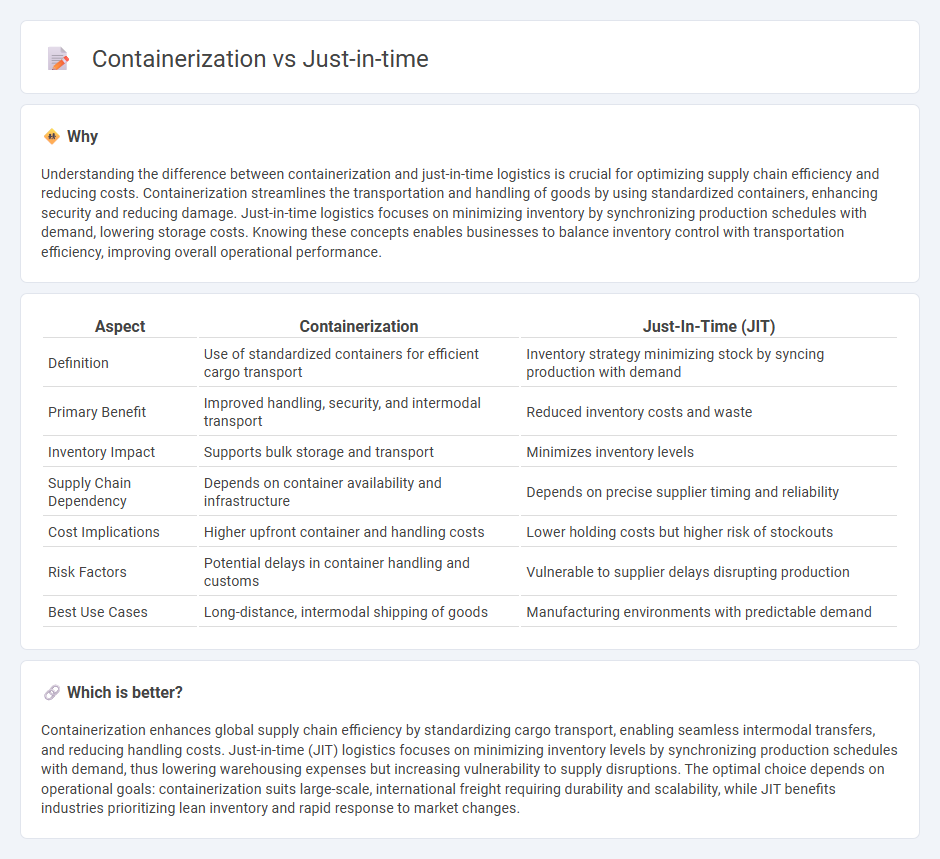

Understanding the difference between containerization and just-in-time logistics is crucial for optimizing supply chain efficiency and reducing costs. Containerization streamlines the transportation and handling of goods by using standardized containers, enhancing security and reducing damage. Just-in-time logistics focuses on minimizing inventory by synchronizing production schedules with demand, lowering storage costs. Knowing these concepts enables businesses to balance inventory control with transportation efficiency, improving overall operational performance.

Comparison Table

| Aspect | Containerization | Just-In-Time (JIT) |

|---|---|---|

| Definition | Use of standardized containers for efficient cargo transport | Inventory strategy minimizing stock by syncing production with demand |

| Primary Benefit | Improved handling, security, and intermodal transport | Reduced inventory costs and waste |

| Inventory Impact | Supports bulk storage and transport | Minimizes inventory levels |

| Supply Chain Dependency | Depends on container availability and infrastructure | Depends on precise supplier timing and reliability |

| Cost Implications | Higher upfront container and handling costs | Lower holding costs but higher risk of stockouts |

| Risk Factors | Potential delays in container handling and customs | Vulnerable to supplier delays disrupting production |

| Best Use Cases | Long-distance, intermodal shipping of goods | Manufacturing environments with predictable demand |

Which is better?

Containerization enhances global supply chain efficiency by standardizing cargo transport, enabling seamless intermodal transfers, and reducing handling costs. Just-in-time (JIT) logistics focuses on minimizing inventory levels by synchronizing production schedules with demand, thus lowering warehousing expenses but increasing vulnerability to supply disruptions. The optimal choice depends on operational goals: containerization suits large-scale, international freight requiring durability and scalability, while JIT benefits industries prioritizing lean inventory and rapid response to market changes.

Connection

Containerization streamlines the handling and transportation of goods by using standardized containers, significantly reducing loading and unloading times. Just-in-time (JIT) inventory management relies on this efficiency to minimize inventory levels and ensure timely delivery of materials to production lines. Together, they optimize supply chain performance by enhancing speed, reducing costs, and improving reliability in logistics operations.

Key Terms

Inventory Management

Just-in-time (JIT) inventory management minimizes excess stock by synchronizing material orders with production schedules, reducing carrying costs and waste. Containerization streamlines the transportation and storage of goods, enhancing visibility and protection during distribution but does not directly reduce inventory levels. Explore how integrating JIT with containerization can optimize supply chain efficiency and inventory control.

Standardization

Just-in-time (JIT) manufacturing emphasizes reducing waste by producing items only as needed, requiring precise timing and process standardization to maintain efficiency across supply chains. Containerization standardizes shipping by using uniform containers, facilitating seamless global trade and reducing handling times. Explore how these standardization approaches transform operational workflows and logistics management.

Lead Time

Just-in-time (JIT) manufacturing minimizes lead time by producing goods only as needed, reducing inventory and accelerating response to demand fluctuations. Containerization streamlines supply chains by standardizing shipment units, enabling faster loading, transportation, and unloading, thereby cutting down overall lead time. Explore in-depth strategies to optimize lead time through JIT and containerization techniques.

Source and External Links

Just-in-Time (JIT) Inventory - Just-in-time inventory is a management strategy that ensures raw materials arrive just as production begins to minimize inventory and maximize efficiency.

JIT Just-in-Time Manufacturing - JIT manufacturing is a philosophy aimed at producing goods to meet exact customer demand, focusing on eliminating waste and improving process efficiency.

What is Just-in-Time Manufacturing (JIT)? - JIT manufacturing is a workflow methodology that reduces production times and costs by streamlining processes and supplier response times.

dowidth.com

dowidth.com