Cold chain traceability ensures the continuous monitoring of temperature-sensitive products, maintaining product integrity from origin to destination through precise data logging and alerts. RFID technology enhances this process by providing real-time tracking and automated data capture, reducing human error and improving supply chain transparency. Discover how integrating these technologies can revolutionize cold chain logistics efficiency and security.

Why it is important

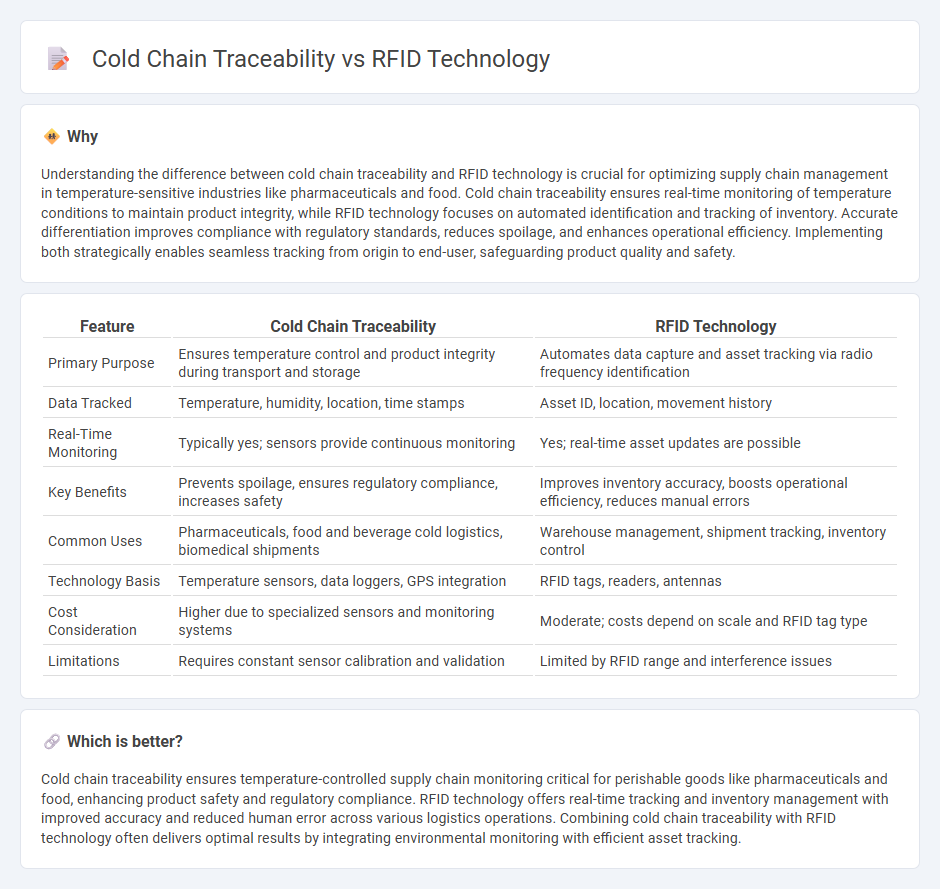

Understanding the difference between cold chain traceability and RFID technology is crucial for optimizing supply chain management in temperature-sensitive industries like pharmaceuticals and food. Cold chain traceability ensures real-time monitoring of temperature conditions to maintain product integrity, while RFID technology focuses on automated identification and tracking of inventory. Accurate differentiation improves compliance with regulatory standards, reduces spoilage, and enhances operational efficiency. Implementing both strategically enables seamless tracking from origin to end-user, safeguarding product quality and safety.

Comparison Table

| Feature | Cold Chain Traceability | RFID Technology |

|---|---|---|

| Primary Purpose | Ensures temperature control and product integrity during transport and storage | Automates data capture and asset tracking via radio frequency identification |

| Data Tracked | Temperature, humidity, location, time stamps | Asset ID, location, movement history |

| Real-Time Monitoring | Typically yes; sensors provide continuous monitoring | Yes; real-time asset updates are possible |

| Key Benefits | Prevents spoilage, ensures regulatory compliance, increases safety | Improves inventory accuracy, boosts operational efficiency, reduces manual errors |

| Common Uses | Pharmaceuticals, food and beverage cold logistics, biomedical shipments | Warehouse management, shipment tracking, inventory control |

| Technology Basis | Temperature sensors, data loggers, GPS integration | RFID tags, readers, antennas |

| Cost Consideration | Higher due to specialized sensors and monitoring systems | Moderate; costs depend on scale and RFID tag type |

| Limitations | Requires constant sensor calibration and validation | Limited by RFID range and interference issues |

Which is better?

Cold chain traceability ensures temperature-controlled supply chain monitoring critical for perishable goods like pharmaceuticals and food, enhancing product safety and regulatory compliance. RFID technology offers real-time tracking and inventory management with improved accuracy and reduced human error across various logistics operations. Combining cold chain traceability with RFID technology often delivers optimal results by integrating environmental monitoring with efficient asset tracking.

Connection

Cold chain traceability relies heavily on RFID technology to monitor temperature-sensitive goods throughout the supply chain, ensuring product integrity and regulatory compliance. RFID tags provide real-time data capture and tracking, enabling precise monitoring of environmental conditions and location during transit and storage. Integration of RFID enhances visibility, reduces spoilage, and supports efficient inventory management in cold chain logistics.

Key Terms

Radio Frequency Identification (RFID)

Radio Frequency Identification (RFID) technology enhances cold chain traceability by enabling real-time monitoring and precise tracking of temperature-sensitive products throughout the supply chain, reducing spoilage and ensuring safety compliance. RFID tags transmit critical data such as temperature, humidity, and location to centralized systems, providing accurate and automatic visibility over perishable goods during transportation and storage. Explore how RFID technology revolutionizes cold chain management with increased efficiency and reliability.

Temperature Monitoring

RFID technology enhances cold chain traceability by providing real-time temperature monitoring through embedded sensors, ensuring product integrity during transportation and storage. This system allows for accurate data collection, automated alerts for temperature deviations, and reduces the risk of spoilage in pharmaceuticals, food, and perishable goods. Explore more about how RFID-driven temperature monitoring revolutionizes cold chain management efficiency and compliance.

Real-time Tracking

RFID technology enables precise real-time tracking of products in cold chain logistics by automatically capturing temperature, location, and movement data through embedded sensors and tags. Cold chain traceability relies heavily on integrating RFID with IoT platforms to monitor perishable goods, ensuring compliance with regulatory standards and minimizing spoilage risks. Explore how combining RFID with advanced analytics enhances transparency and efficiency in cold chain management.

Source and External Links

Radio-frequency identification - RFID uses electromagnetic fields to automatically identify and track tags attached to objects, with passive tags powered by reader waves and active tags by batteries, enabling tracking without line of sight and used in diverse industries like automotive, pharmaceuticals, and livestock identification.

Radio Frequency Identification (RFID) in health care - RFID technology captures and transfers data via radio waves efficiently and automatically, widely used in healthcare for real-time tracking of patients, personnel, and assets without contact and enabling simultaneous reading of multiple tags at a distance.

What is RFID Technology and How Does It Work? (2025) - RFID technology transmits data between tags and readers using radio waves for applications including inventory and supply chain tracking, temperature monitoring of perishables, theft prevention, patient safety, and access control, providing real-time visibility and improved security.

dowidth.com

dowidth.com