Cold chain management ensures the integrity of temperature-sensitive products throughout the supply chain, minimizing spoilage and maintaining quality. Procurement focuses on sourcing the right goods and services at optimal costs to support logistics operations efficiently. Discover how integrating cold chain management and procurement enhances supply chain performance.

Why it is important

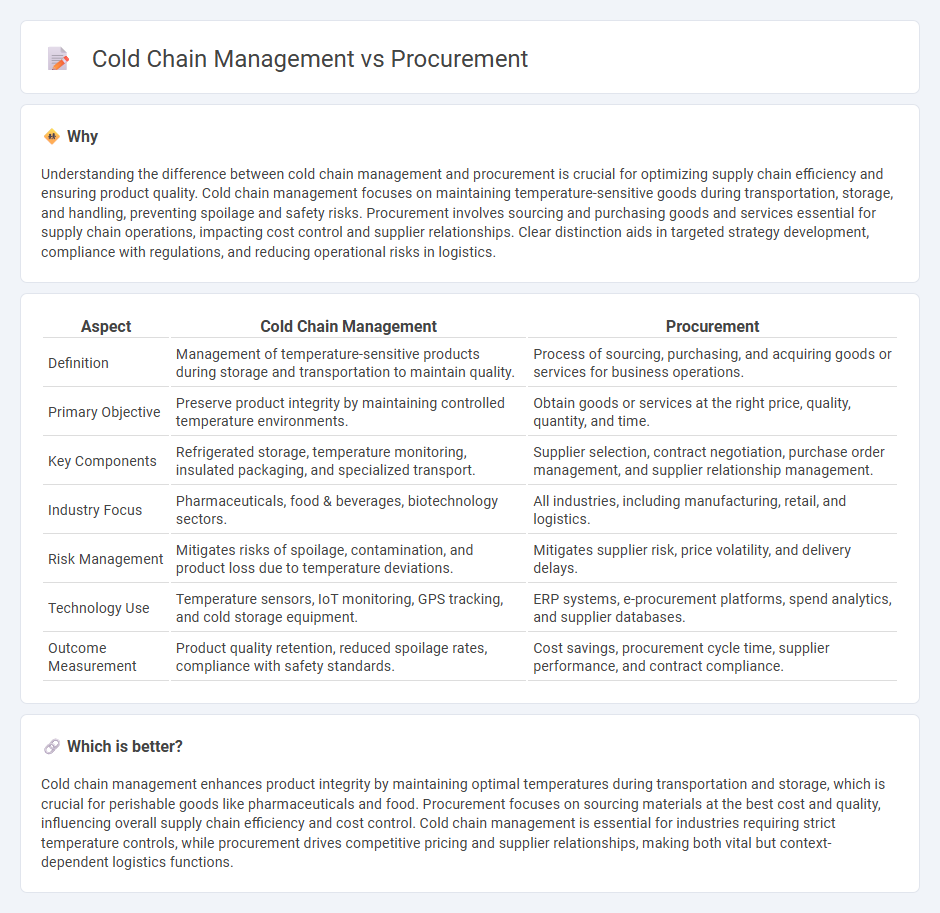

Understanding the difference between cold chain management and procurement is crucial for optimizing supply chain efficiency and ensuring product quality. Cold chain management focuses on maintaining temperature-sensitive goods during transportation, storage, and handling, preventing spoilage and safety risks. Procurement involves sourcing and purchasing goods and services essential for supply chain operations, impacting cost control and supplier relationships. Clear distinction aids in targeted strategy development, compliance with regulations, and reducing operational risks in logistics.

Comparison Table

| Aspect | Cold Chain Management | Procurement |

|---|---|---|

| Definition | Management of temperature-sensitive products during storage and transportation to maintain quality. | Process of sourcing, purchasing, and acquiring goods or services for business operations. |

| Primary Objective | Preserve product integrity by maintaining controlled temperature environments. | Obtain goods or services at the right price, quality, quantity, and time. |

| Key Components | Refrigerated storage, temperature monitoring, insulated packaging, and specialized transport. | Supplier selection, contract negotiation, purchase order management, and supplier relationship management. |

| Industry Focus | Pharmaceuticals, food & beverages, biotechnology sectors. | All industries, including manufacturing, retail, and logistics. |

| Risk Management | Mitigates risks of spoilage, contamination, and product loss due to temperature deviations. | Mitigates supplier risk, price volatility, and delivery delays. |

| Technology Use | Temperature sensors, IoT monitoring, GPS tracking, and cold storage equipment. | ERP systems, e-procurement platforms, spend analytics, and supplier databases. |

| Outcome Measurement | Product quality retention, reduced spoilage rates, compliance with safety standards. | Cost savings, procurement cycle time, supplier performance, and contract compliance. |

Which is better?

Cold chain management enhances product integrity by maintaining optimal temperatures during transportation and storage, which is crucial for perishable goods like pharmaceuticals and food. Procurement focuses on sourcing materials at the best cost and quality, influencing overall supply chain efficiency and cost control. Cold chain management is essential for industries requiring strict temperature controls, while procurement drives competitive pricing and supplier relationships, making both vital but context-dependent logistics functions.

Connection

Cold chain management ensures the integrity of temperature-sensitive products throughout the supply chain, making it critical for procurement strategies that prioritize quality and compliance. Procurement teams collaborate closely with cold chain logistics providers to select reliable vendors capable of maintaining stringent temperature controls during transportation and storage. Integrating cold chain requirements into procurement processes reduces spoilage risks and supports regulatory adherence in industries like pharmaceuticals and perishable foods.

Key Terms

Procurement:

Procurement involves the strategic sourcing, negotiation, and acquisition of goods and services essential for business operations, with a strong emphasis on cost efficiency, supplier reliability, and quality assurance. In contrast, cold chain management focuses on maintaining temperature-controlled supply chains to preserve the integrity of perishable products, particularly in pharmaceuticals and food industries. Explore comprehensive insights to understand how procurement strategies optimize supply chain performance and drive operational excellence.

Supplier Selection

Supplier selection in procurement emphasizes evaluating vendors based on price, quality, reliability, and delivery timelines to ensure cost-effective sourcing. Cold chain management prioritizes selecting suppliers with expertise in temperature-controlled logistics, certifications, and robust tracking systems to maintain product integrity from origin to destination. Explore detailed strategies to optimize supplier selection in both procurement and cold chain management.

Purchase Order

Procurement and cold chain management both involve purchase orders, but procurement centers on acquiring goods and services efficiently across industries, while cold chain management focuses on purchasing temperature-sensitive products and specialized equipment to maintain product integrity. A precise purchase order in cold chain management includes detailed specifications on temperature requirements, packaging, and delivery schedules to ensure compliance with safety standards. Explore how optimized purchase order processes enhance reliability across both procurement and cold chain operations.

Source and External Links

Procurement - Procurement is a strategic process for ethically purchasing quality goods and services, involving steps like identifying needs and managing purchase orders.

What is Procurement? - Procurement involves acquiring goods and services for business operations, focusing on efficiency and value while maintaining relationships with suppliers.

What Is Procurement? - Procurement is the end-to-end process of obtaining goods or services needed for day-to-day business operations, ensuring cost efficiency and supply consistency.

dowidth.com

dowidth.com