Cold chain traceability ensures temperature-sensitive products remain within regulated conditions through continuous monitoring and data logging. IoT integration enhances this process by enabling real-time tracking, automated alerts, and remote management of cold chain assets, improving efficiency and reducing product spoilage. Discover how combining cold chain traceability with IoT technology revolutionizes logistics management.

Why it is important

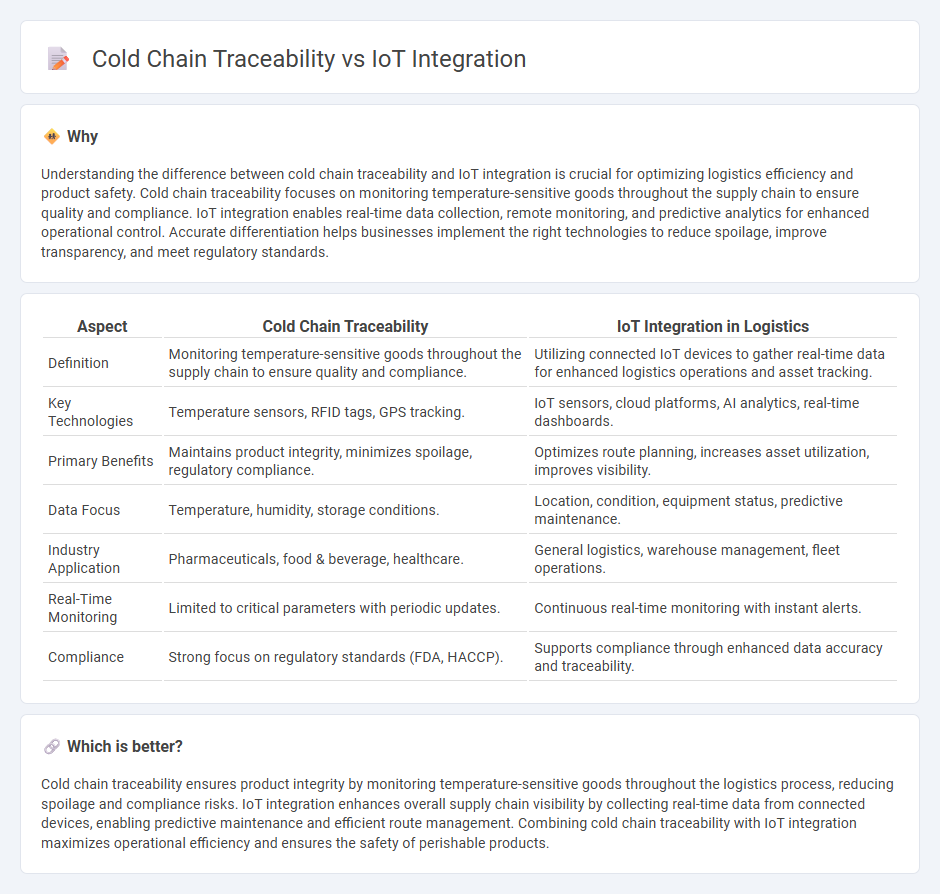

Understanding the difference between cold chain traceability and IoT integration is crucial for optimizing logistics efficiency and product safety. Cold chain traceability focuses on monitoring temperature-sensitive goods throughout the supply chain to ensure quality and compliance. IoT integration enables real-time data collection, remote monitoring, and predictive analytics for enhanced operational control. Accurate differentiation helps businesses implement the right technologies to reduce spoilage, improve transparency, and meet regulatory standards.

Comparison Table

| Aspect | Cold Chain Traceability | IoT Integration in Logistics |

|---|---|---|

| Definition | Monitoring temperature-sensitive goods throughout the supply chain to ensure quality and compliance. | Utilizing connected IoT devices to gather real-time data for enhanced logistics operations and asset tracking. |

| Key Technologies | Temperature sensors, RFID tags, GPS tracking. | IoT sensors, cloud platforms, AI analytics, real-time dashboards. |

| Primary Benefits | Maintains product integrity, minimizes spoilage, regulatory compliance. | Optimizes route planning, increases asset utilization, improves visibility. |

| Data Focus | Temperature, humidity, storage conditions. | Location, condition, equipment status, predictive maintenance. |

| Industry Application | Pharmaceuticals, food & beverage, healthcare. | General logistics, warehouse management, fleet operations. |

| Real-Time Monitoring | Limited to critical parameters with periodic updates. | Continuous real-time monitoring with instant alerts. |

| Compliance | Strong focus on regulatory standards (FDA, HACCP). | Supports compliance through enhanced data accuracy and traceability. |

Which is better?

Cold chain traceability ensures product integrity by monitoring temperature-sensitive goods throughout the logistics process, reducing spoilage and compliance risks. IoT integration enhances overall supply chain visibility by collecting real-time data from connected devices, enabling predictive maintenance and efficient route management. Combining cold chain traceability with IoT integration maximizes operational efficiency and ensures the safety of perishable products.

Connection

Cold chain traceability relies heavily on IoT integration to monitor temperature, humidity, and location in real-time, ensuring product quality and safety throughout the supply chain. IoT devices generate continuous data streams that enable precise tracking and instant alerts for deviations, minimizing spoilage and compliance risks. This technology synergy enhances transparency, operational efficiency, and regulatory compliance in perishable goods logistics.

Key Terms

Sensors

IoT integration enhances cold chain traceability by enabling real-time monitoring through advanced sensors that track temperature, humidity, and location data with high precision. These sensors facilitate immediate alerts and data analytics, reducing spoilage and ensuring compliance with regulatory standards in industries such as pharmaceuticals and food logistics. Discover how cutting-edge sensor technologies drive efficient cold chain management and improve supply chain transparency.

Real-time monitoring

Real-time monitoring in IoT integration enables continuous tracking of environmental conditions, ensuring optimal temperature and humidity levels throughout the cold chain. Advanced sensors and IoT platforms facilitate instant data transmission and analytics, reducing spoilage and enhancing compliance with regulatory standards. Explore how real-time IoT monitoring revolutionizes cold chain traceability and improves supply chain efficiency.

Temperature tracking

IoT integration in temperature tracking enables real-time monitoring and precise data collection, enhancing cold chain traceability by reducing spoilage and ensuring regulatory compliance. Sensors linked via IoT platforms provide continuous temperature updates and alerts, facilitating immediate corrective actions during transport and storage. Explore how advanced IoT solutions transform cold chain management to guarantee product quality and safety.

Source and External Links

Integration with Internet of Things (IoT): Everything You Need To Know - IoT integration is the seamless connection of IoT devices and systems for data sharing, enhanced by AI, ML, 5G, and blockchain technologies to create autonomous, efficient, and secure IoT ecosystems.

What Is IoT Integration? A Guide to Overcoming Challenges - IoT integration links smart devices, applications, and databases to enable data exchange and automated workflows, crucial for industries such as manufacturing and smart cities, with IoT gateways facilitating secure and efficient data transmission.

What Is IoT Integration? A Comprehensive Guide - Workato - IoT integration leverages real-time device data to improve operational efficiency, reduce costs, and support sustainability, involving steps like defining goals, selecting devices, using integration platforms, setting up gateways, ensuring security, and automating workflows.

dowidth.com

dowidth.com