Quick commerce revolutionizes last-mile delivery through rapid order fulfillment enabled by proximity-based micro-fulfillment centers. Warehouse automation integrates robotics, AI, and IoT systems to enhance inventory management, reduce errors, and accelerate order processing. Explore how combining these innovations can optimize supply chains and meet evolving consumer demands.

Why it is important

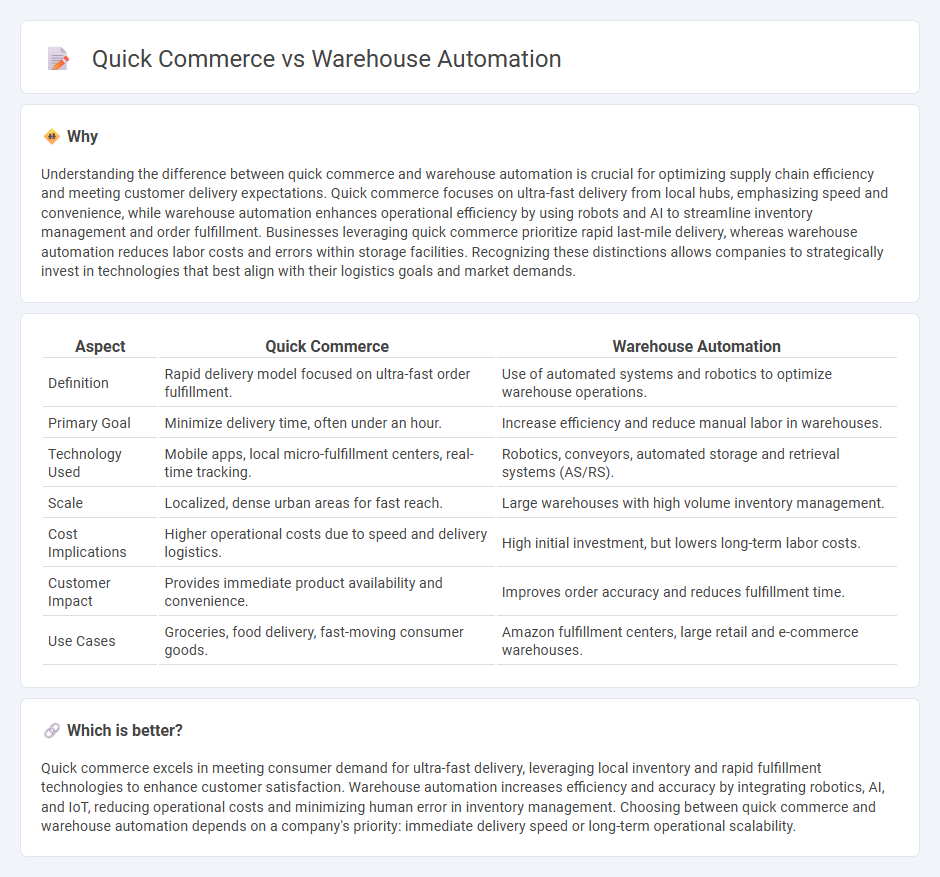

Understanding the difference between quick commerce and warehouse automation is crucial for optimizing supply chain efficiency and meeting customer delivery expectations. Quick commerce focuses on ultra-fast delivery from local hubs, emphasizing speed and convenience, while warehouse automation enhances operational efficiency by using robots and AI to streamline inventory management and order fulfillment. Businesses leveraging quick commerce prioritize rapid last-mile delivery, whereas warehouse automation reduces labor costs and errors within storage facilities. Recognizing these distinctions allows companies to strategically invest in technologies that best align with their logistics goals and market demands.

Comparison Table

| Aspect | Quick Commerce | Warehouse Automation |

|---|---|---|

| Definition | Rapid delivery model focused on ultra-fast order fulfillment. | Use of automated systems and robotics to optimize warehouse operations. |

| Primary Goal | Minimize delivery time, often under an hour. | Increase efficiency and reduce manual labor in warehouses. |

| Technology Used | Mobile apps, local micro-fulfillment centers, real-time tracking. | Robotics, conveyors, automated storage and retrieval systems (AS/RS). |

| Scale | Localized, dense urban areas for fast reach. | Large warehouses with high volume inventory management. |

| Cost Implications | Higher operational costs due to speed and delivery logistics. | High initial investment, but lowers long-term labor costs. |

| Customer Impact | Provides immediate product availability and convenience. | Improves order accuracy and reduces fulfillment time. |

| Use Cases | Groceries, food delivery, fast-moving consumer goods. | Amazon fulfillment centers, large retail and e-commerce warehouses. |

Which is better?

Quick commerce excels in meeting consumer demand for ultra-fast delivery, leveraging local inventory and rapid fulfillment technologies to enhance customer satisfaction. Warehouse automation increases efficiency and accuracy by integrating robotics, AI, and IoT, reducing operational costs and minimizing human error in inventory management. Choosing between quick commerce and warehouse automation depends on a company's priority: immediate delivery speed or long-term operational scalability.

Connection

Quick commerce relies heavily on warehouse automation to accelerate order fulfillment and reduce delivery times by utilizing robotics, automated sorting systems, and real-time inventory management. Advanced warehouse automation enhances operational efficiency, enabling rapid picking, packing, and dispatching processes essential for meeting the immediate demands of quick commerce. Integration of automated warehouses with digital platforms ensures seamless synchronization between inventory levels and customer orders, driving faster and more accurate logistics performance.

Key Terms

Robotics

Warehouse automation leverages advanced robotics to enhance inventory handling, order picking, and packing efficiency, drastically reducing human error and labor costs. Quick commerce relies on robotic systems for ultra-fast fulfillment, optimizing last-mile delivery by integrating AI-driven robots that navigate tight urban environments. Explore the transformative impact of robotics on supply chain speed and accuracy to understand the future of both warehouse automation and quick commerce.

Last-mile Delivery

Warehouse automation enhances last-mile delivery efficiency by streamlining inventory management and reducing order processing times with robotics and AI-driven systems. Quick commerce prioritizes ultra-fast delivery within minutes by leveraging localized micro-fulfillment centers and intelligent routing algorithms. Explore how integrating these technologies can revolutionize last-mile logistics and boost customer satisfaction.

Inventory Turnover

Warehouse automation significantly enhances inventory turnover by streamlining stock handling, reducing errors, and accelerating order fulfillment processes. Quick commerce depends on rapid inventory replenishment and immediate stock availability, making high turnover rates essential to meet customer expectations for fast delivery. Explore effective strategies to optimize inventory turnover by balancing warehouse automation with quick commerce demands.

Source and External Links

Warehouse Automation Explained: Trends, Types & Best Practices - Warehouse automation automates inventory movement with minimal human help, involving steps like forming expert committees, collecting essential data, refining inventory controls, implementing warehouse management systems (WMS), and choosing automation types based on goals.

13 Warehouse Automation Trends in 2025 - Conger Industries - Key steps for warehouse automation include feasibility studies, defining goals, budget planning, stakeholder involvement, and choosing hardware like automated storage systems and autonomous robots, along with software integration to existing enterprise systems.

Warehouse Automation Solutions | Maveneer - Modern warehouse automation integrates software (WMS, TMS, ERP) and hardware (robots, conveyors, AMRs) with real-time data visibility to create intelligent, connected ecosystems that optimize goods movement and inventory management.

dowidth.com

dowidth.com