Pop-up warehousing offers flexible, temporary storage solutions ideal for managing seasonal demand spikes and reducing last-mile delivery times, while fulfillment centers provide permanent, large-scale operations designed for systematic inventory management and order processing. Key differences include pop-up warehouses' quick setup and scalability compared to the established infrastructure and automation found in fulfillment centers. Explore these logistics strategies further to optimize your supply chain efficiency and customer satisfaction.

Why it is important

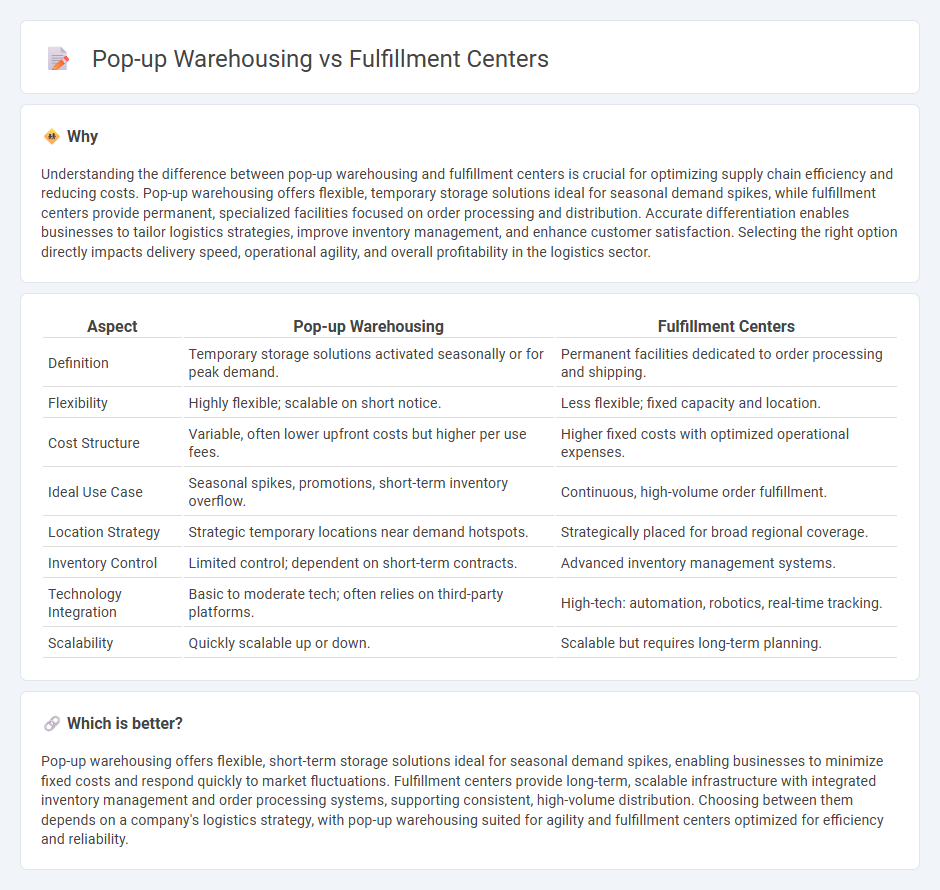

Understanding the difference between pop-up warehousing and fulfillment centers is crucial for optimizing supply chain efficiency and reducing costs. Pop-up warehousing offers flexible, temporary storage solutions ideal for seasonal demand spikes, while fulfillment centers provide permanent, specialized facilities focused on order processing and distribution. Accurate differentiation enables businesses to tailor logistics strategies, improve inventory management, and enhance customer satisfaction. Selecting the right option directly impacts delivery speed, operational agility, and overall profitability in the logistics sector.

Comparison Table

| Aspect | Pop-up Warehousing | Fulfillment Centers |

|---|---|---|

| Definition | Temporary storage solutions activated seasonally or for peak demand. | Permanent facilities dedicated to order processing and shipping. |

| Flexibility | Highly flexible; scalable on short notice. | Less flexible; fixed capacity and location. |

| Cost Structure | Variable, often lower upfront costs but higher per use fees. | Higher fixed costs with optimized operational expenses. |

| Ideal Use Case | Seasonal spikes, promotions, short-term inventory overflow. | Continuous, high-volume order fulfillment. |

| Location Strategy | Strategic temporary locations near demand hotspots. | Strategically placed for broad regional coverage. |

| Inventory Control | Limited control; dependent on short-term contracts. | Advanced inventory management systems. |

| Technology Integration | Basic to moderate tech; often relies on third-party platforms. | High-tech: automation, robotics, real-time tracking. |

| Scalability | Quickly scalable up or down. | Scalable but requires long-term planning. |

Which is better?

Pop-up warehousing offers flexible, short-term storage solutions ideal for seasonal demand spikes, enabling businesses to minimize fixed costs and respond quickly to market fluctuations. Fulfillment centers provide long-term, scalable infrastructure with integrated inventory management and order processing systems, supporting consistent, high-volume distribution. Choosing between them depends on a company's logistics strategy, with pop-up warehousing suited for agility and fulfillment centers optimized for efficiency and reliability.

Connection

Pop-up warehousing and fulfillment centers offer flexible storage and distribution solutions that optimize supply chain efficiency during peak demand periods and market fluctuations. These temporary facilities reduce last-mile delivery costs and improve order accuracy by positioning inventory closer to end consumers. Integrating pop-up warehousing with fulfillment centers enables businesses to scale operations dynamically, enhancing responsiveness and reducing delivery lead times.

Key Terms

Inventory Management

Fulfillment centers specialize in long-term inventory storage and streamlined order processing, leveraging advanced warehouse management systems (WMS) for real-time tracking and accuracy. Pop-up warehousing offers flexible, short-term storage solutions that adapt quickly to seasonal demand spikes but may lack the sophisticated inventory controls of established fulfillment centers. Explore how your business can optimize inventory management through strategic use of fulfillment centers and pop-up warehousing.

Scalability

Fulfillment centers offer long-term scalability with established infrastructure supporting high-volume order processing, while pop-up warehousing provides flexible, short-term scalability ideal for seasonal spikes and market testing. Pop-up warehouses enable rapid deployment and adaptability without the commitment to large-scale space, making them cost-effective for fluctuating inventory demands. Explore detailed comparisons to determine the best scalable solution for your logistics needs.

Distribution Speed

Fulfillment centers operate with established infrastructure and advanced inventory systems, enabling faster order processing and shipping for e-commerce and retail businesses. Pop-up warehousing offers temporary, flexible storage solutions that can strategically boost distribution speed during peak seasons or demand surges but may lack the consistency of permanent centers. Explore the advantages and use cases of each to optimize your supply chain efficiency.

Source and External Links

What is a Fulfillment Center and How Can it Help Your Ecommerce ... - A fulfillment center is a large facility where sellers or third-party logistics providers (3PLs) manage inventory, pick, pack, and ship customer orders, serving both direct-to-consumer and business-to-retail fulfillment needs, streamlining the entire shipping process and often reducing costs for sellers.

Fulfillment Centers - CDTFA - CA.gov - Fulfillment centers are warehouse facilities that handle packaging and shipping of orders to customers, allowing sellers to outsource warehousing and shipping to minimize costs and speed delivery.

Fulfillment Center & Warehouse Services: Succeed With Both - A fulfillment center functions as the logistics hub in the supply chain, receiving inventory, fulfilling ecommerce orders by picking, packing, and shipping, and can be operated by businesses themselves or third-party logistics providers to improve efficiency and customer service.

dowidth.com

dowidth.com