Pick and pack and sortation are critical processes in modern logistics, directly impacting efficiency and order accuracy. Pick and pack focuses on selecting individual items and packaging them for shipment, optimizing warehouse operations for speed and precision. Explore in-depth differences and best practices to enhance your supply chain performance.

Why it is important

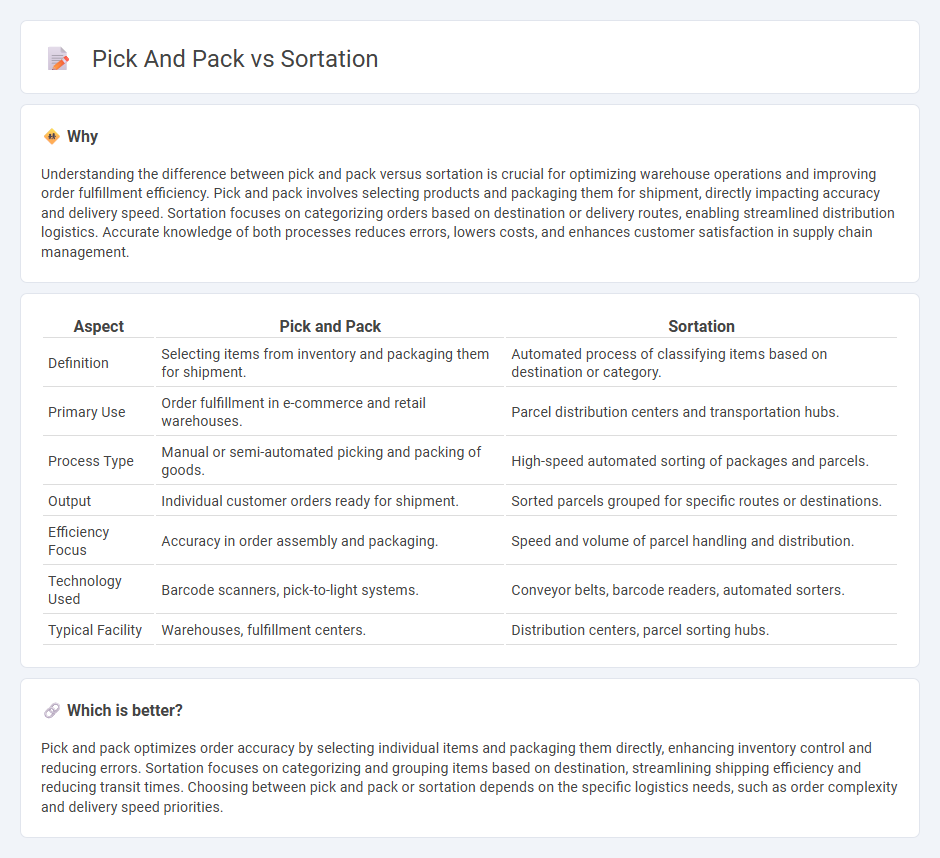

Understanding the difference between pick and pack versus sortation is crucial for optimizing warehouse operations and improving order fulfillment efficiency. Pick and pack involves selecting products and packaging them for shipment, directly impacting accuracy and delivery speed. Sortation focuses on categorizing orders based on destination or delivery routes, enabling streamlined distribution logistics. Accurate knowledge of both processes reduces errors, lowers costs, and enhances customer satisfaction in supply chain management.

Comparison Table

| Aspect | Pick and Pack | Sortation |

|---|---|---|

| Definition | Selecting items from inventory and packaging them for shipment. | Automated process of classifying items based on destination or category. |

| Primary Use | Order fulfillment in e-commerce and retail warehouses. | Parcel distribution centers and transportation hubs. |

| Process Type | Manual or semi-automated picking and packing of goods. | High-speed automated sorting of packages and parcels. |

| Output | Individual customer orders ready for shipment. | Sorted parcels grouped for specific routes or destinations. |

| Efficiency Focus | Accuracy in order assembly and packaging. | Speed and volume of parcel handling and distribution. |

| Technology Used | Barcode scanners, pick-to-light systems. | Conveyor belts, barcode readers, automated sorters. |

| Typical Facility | Warehouses, fulfillment centers. | Distribution centers, parcel sorting hubs. |

Which is better?

Pick and pack optimizes order accuracy by selecting individual items and packaging them directly, enhancing inventory control and reducing errors. Sortation focuses on categorizing and grouping items based on destination, streamlining shipping efficiency and reducing transit times. Choosing between pick and pack or sortation depends on the specific logistics needs, such as order complexity and delivery speed priorities.

Connection

Pick and pack and sortation are integral processes in logistics, directly influencing order fulfillment efficiency. Pick and pack involves selecting products from inventory and packaging them for shipment, while sortation arranges these packages based on destination or delivery routes. Synchronizing these functions reduces errors, accelerates distribution, and optimizes warehouse workflow.

Key Terms

Automation

Sortation systems automate the process of categorizing and directing packages to specific destinations, significantly increasing throughput and accuracy in warehouses. Pick and pack automation employs robotic arms and conveyor systems to retrieve items and prepare shipments, reducing labor costs and minimizing errors. Explore how integrating advanced automation in both sortation and pick and pack can revolutionize your logistics operations.

Order fulfillment

Sortation streamlines order fulfillment by organizing items based on their destination, enhancing efficiency in distribution centers. Pick and pack involves selecting ordered products from inventory and packaging them for shipment, directly impacting delivery speed and accuracy. Explore detailed insights to optimize your order fulfillment strategy.

Throughput

Sortation systems optimize throughput by rapidly categorizing and directing items to designated locations, significantly reducing manual handling time. Pick and pack operations focus on accuracy and order completeness, often resulting in slower throughput due to individualized item retrieval and packing. Explore detailed comparisons and best practices to maximize throughput efficiency in your warehouse.

Source and External Links

Sortation Systems | Automated Material Handling Technologies - Sortation solutions automatically identify and transport products within a facility to appropriate destinations, streamlining sorting and distribution tasks with scalable robotic and conveyor systems for high efficiency and flexibility in order fulfillment operations.

What is a Sortation System? - Burwell Material Handling - A sortation system is an automated solution that uses conveyors, diverters, sensors, and control systems to rapidly sort and direct high volumes of items or packages to designated locations or next processing steps in warehouses and distribution centers.

SORTATION definition in American English - Collins Dictionary - Sortation is defined as the process of sorting items into groups based on a shared distinguishing quality or characteristic.

dowidth.com

dowidth.com