Robotic Process Automation (RPA) in logistics streamlines repetitive tasks such as inventory tracking and shipment scheduling, significantly reducing human error and operational costs. Order Management Systems (OMS) focus on coordinating order processing from sales through delivery, integrating order data across multiple channels for real-time visibility and customer satisfaction. Explore how the synergy between RPA and OMS transforms logistics efficiency and accuracy.

Why it is important

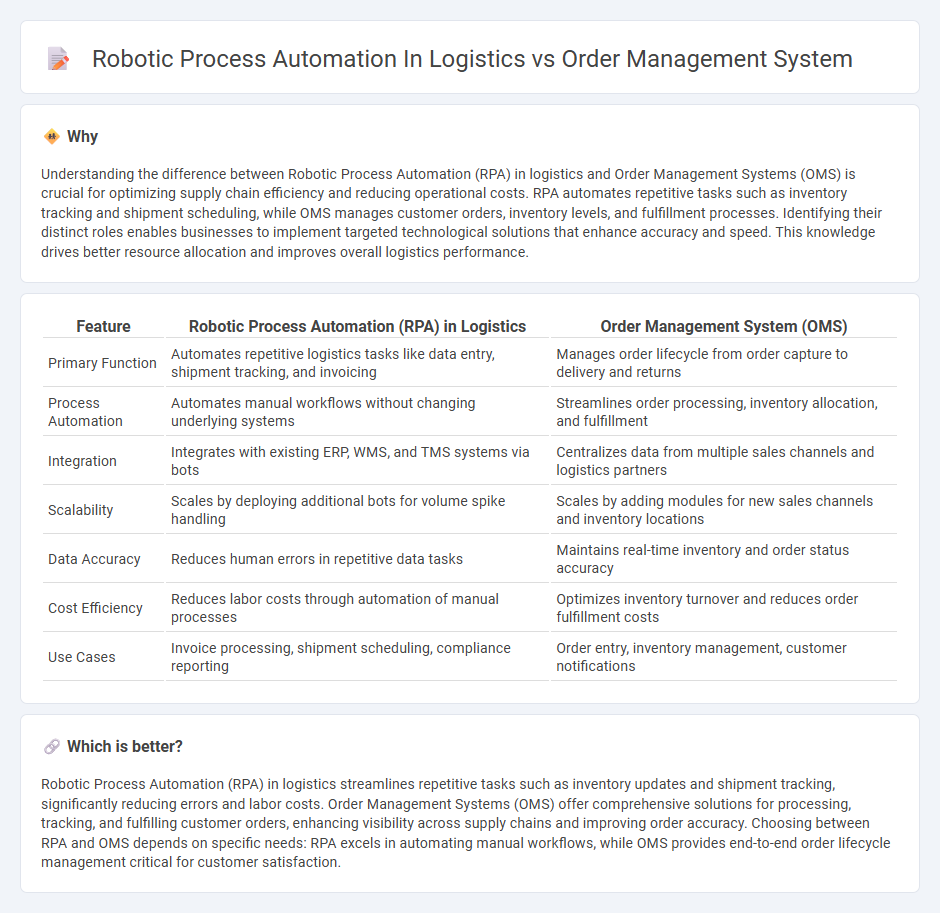

Understanding the difference between Robotic Process Automation (RPA) in logistics and Order Management Systems (OMS) is crucial for optimizing supply chain efficiency and reducing operational costs. RPA automates repetitive tasks such as inventory tracking and shipment scheduling, while OMS manages customer orders, inventory levels, and fulfillment processes. Identifying their distinct roles enables businesses to implement targeted technological solutions that enhance accuracy and speed. This knowledge drives better resource allocation and improves overall logistics performance.

Comparison Table

| Feature | Robotic Process Automation (RPA) in Logistics | Order Management System (OMS) |

|---|---|---|

| Primary Function | Automates repetitive logistics tasks like data entry, shipment tracking, and invoicing | Manages order lifecycle from order capture to delivery and returns |

| Process Automation | Automates manual workflows without changing underlying systems | Streamlines order processing, inventory allocation, and fulfillment |

| Integration | Integrates with existing ERP, WMS, and TMS systems via bots | Centralizes data from multiple sales channels and logistics partners |

| Scalability | Scales by deploying additional bots for volume spike handling | Scales by adding modules for new sales channels and inventory locations |

| Data Accuracy | Reduces human errors in repetitive data tasks | Maintains real-time inventory and order status accuracy |

| Cost Efficiency | Reduces labor costs through automation of manual processes | Optimizes inventory turnover and reduces order fulfillment costs |

| Use Cases | Invoice processing, shipment scheduling, compliance reporting | Order entry, inventory management, customer notifications |

Which is better?

Robotic Process Automation (RPA) in logistics streamlines repetitive tasks such as inventory updates and shipment tracking, significantly reducing errors and labor costs. Order Management Systems (OMS) offer comprehensive solutions for processing, tracking, and fulfilling customer orders, enhancing visibility across supply chains and improving order accuracy. Choosing between RPA and OMS depends on specific needs: RPA excels in automating manual workflows, while OMS provides end-to-end order lifecycle management critical for customer satisfaction.

Connection

Robotic Process Automation (RPA) enhances logistics and order management systems by automating repetitive tasks such as inventory tracking, shipment scheduling, and order processing, increasing operational efficiency and reducing human error. Integration of RPA with Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) allows real-time data synchronization, improving accuracy in demand forecasting and delivery timelines. The use of RPA in logistics streamlines supply chain workflows, optimizes resource allocation, and accelerates customer response times, providing a competitive advantage in fast-paced markets.

Key Terms

Order Management System (OMS):

Order Management System (OMS) streamlines end-to-end order processing by integrating inventory, warehouse, and customer data to improve accuracy and reduce fulfillment time. OMS enhances supply chain visibility, optimizes order tracking, and supports multi-channel sales environments, ensuring timely and precise delivery. Discover how implementing an advanced OMS can transform logistics efficiency and customer satisfaction.

Order Fulfillment

Order Management Systems (OMS) streamline order processing by centralizing order data, inventory, and customer information to enhance accuracy and speed in logistics order fulfillment. Robotic Process Automation (RPA) complements OMS by automating repetitive tasks such as data entry, shipment tracking, and invoice processing, reducing human error and operational costs. Explore how integrating OMS and RPA can revolutionize your logistics order fulfillment for increased efficiency and customer satisfaction.

Inventory Tracking

Order management systems (OMS) streamline inventory tracking by providing real-time stock updates, order status, and demand forecasting to optimize warehouse operations. Robotic Process Automation (RPA) enhances inventory accuracy through automated data entry, error reduction, and seamless integration across multiple logistics platforms. Explore how combining OMS and RPA can revolutionize inventory tracking in logistics.

Source and External Links

What is Order Management? | IBM - An order management system (OMS) is a digital platform that tracks orders from inception to fulfillment, managing people, processes, and data to provide real-time visibility and automate manual tasks, improving supply chain efficiency and customer experience.

What is an Order Management System? | Salesforce US - An OMS is software that allows sellers to track sales, process and fulfill orders, manage inventory, and provide full transparency and fast delivery to customers, streamlining all steps of the order lifecycle from purchase to delivery.

Order management system - Wikipedia - An OMS is a computer software system used in many industries to handle order entry, processing, inventory management, and customer service functions, integrating multiple modules like product info, vendor management, and financial processing to automate and coordinate order fulfillment workflows.

dowidth.com

dowidth.com