Container pooling maximizes efficiency by sharing standardized containers among multiple shippers, reducing empty container returns and cutting costs. Milk run logistics optimizes transport by consolidating multiple deliveries into a single route, minimizing travel time and fuel consumption. Explore our detailed comparison to understand which strategy best suits your supply chain needs.

Why it is important

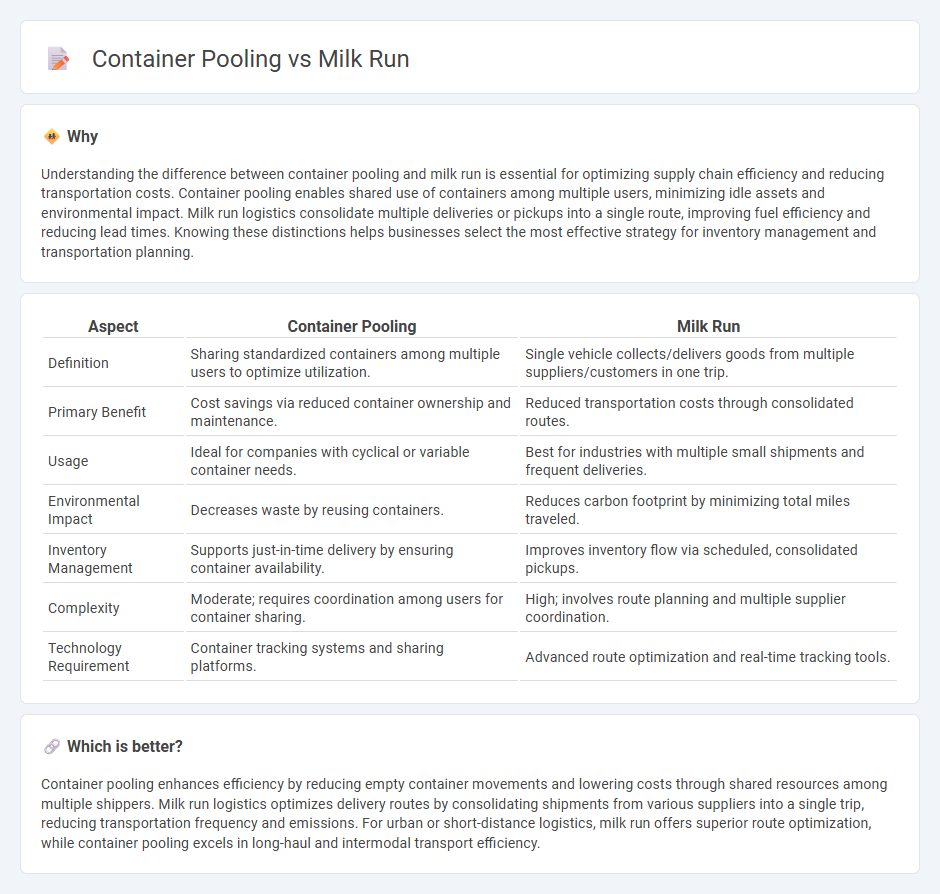

Understanding the difference between container pooling and milk run is essential for optimizing supply chain efficiency and reducing transportation costs. Container pooling enables shared use of containers among multiple users, minimizing idle assets and environmental impact. Milk run logistics consolidate multiple deliveries or pickups into a single route, improving fuel efficiency and reducing lead times. Knowing these distinctions helps businesses select the most effective strategy for inventory management and transportation planning.

Comparison Table

| Aspect | Container Pooling | Milk Run |

|---|---|---|

| Definition | Sharing standardized containers among multiple users to optimize utilization. | Single vehicle collects/delivers goods from multiple suppliers/customers in one trip. |

| Primary Benefit | Cost savings via reduced container ownership and maintenance. | Reduced transportation costs through consolidated routes. |

| Usage | Ideal for companies with cyclical or variable container needs. | Best for industries with multiple small shipments and frequent deliveries. |

| Environmental Impact | Decreases waste by reusing containers. | Reduces carbon footprint by minimizing total miles traveled. |

| Inventory Management | Supports just-in-time delivery by ensuring container availability. | Improves inventory flow via scheduled, consolidated pickups. |

| Complexity | Moderate; requires coordination among users for container sharing. | High; involves route planning and multiple supplier coordination. |

| Technology Requirement | Container tracking systems and sharing platforms. | Advanced route optimization and real-time tracking tools. |

Which is better?

Container pooling enhances efficiency by reducing empty container movements and lowering costs through shared resources among multiple shippers. Milk run logistics optimizes delivery routes by consolidating shipments from various suppliers into a single trip, reducing transportation frequency and emissions. For urban or short-distance logistics, milk run offers superior route optimization, while container pooling excels in long-haul and intermodal transport efficiency.

Connection

Container pooling streamlines logistics by enabling multiple companies to share standardized containers, reducing costs and environmental impact. Milk run transportation complements this by efficiently collecting and delivering goods through scheduled routes, minimizing empty runs and maximizing container utilization. Together, these strategies optimize supply chain efficiency and sustainability through coordinated resource sharing and route planning.

Key Terms

Milk Run:

Milk Run logistics optimize supply chain efficiency by consolidating multiple supplier shipments into a single route, reducing transportation costs and minimizing inventory levels. This method enhances delivery frequency and reliability, tailored for industries requiring just-in-time inventory management. Discover how Milk Run strategies can transform your supply chain operations.

Route Optimization

Milk run routing consolidates multiple deliveries into a single trip, significantly reducing transportation costs and improving fuel efficiency by minimizing empty runs. Container pooling, while optimizing container utilization and reducing inventory holding costs, can also enhance route planning by ensuring standardized containers are available for efficient loading and unloading. Explore detailed strategies to leverage milk run and container pooling for superior route optimization in logistics management.

Consolidation

Milk run logistics optimize consolidation by collecting smaller shipments from multiple suppliers into a single delivery, reducing transportation costs and enhancing route efficiency. Container pooling streamlines consolidation through shared use of standardized containers across multiple shippers, maximizing container utilization and minimizing empty runs. Explore how integrating these strategies can drive cost savings and sustainability in your supply chain.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - ShipBob - Milk run is a logistics strategy where a single vehicle collects goods from multiple suppliers and delivers them together to a single destination, a practice that originated from dairy milk collection routines to ensure fresh supply and avoid overstocking.

What is a milk run in logistics? | Red Stag Fulfillment - In logistics, a milk run refers to a recurring, pre-defined route to pick up and deliver goods to multiple stops, optimizing inventory replenishment and reducing transportation costs by consolidating shipments from various suppliers in one trip.

Milk Run - Lean Enterprise Institute - Milk run is a lean logistics method where vehicles make frequent multiple pick-ups and drop-offs along a route to speed the flow of materials between facilities, reduce inventory levels, and shorten response times in the supply chain.

dowidth.com

dowidth.com