Empty miles reduction in logistics focuses on minimizing the distance trucks travel without cargo, enhancing fuel efficiency and lowering operational costs. Drop-and-hook operations optimize asset utilization by allowing drivers to drop off a loaded trailer and immediately pick up another, reducing wait times and improving delivery speed. Explore effective strategies to balance these approaches and boost logistics performance.

Why it is important

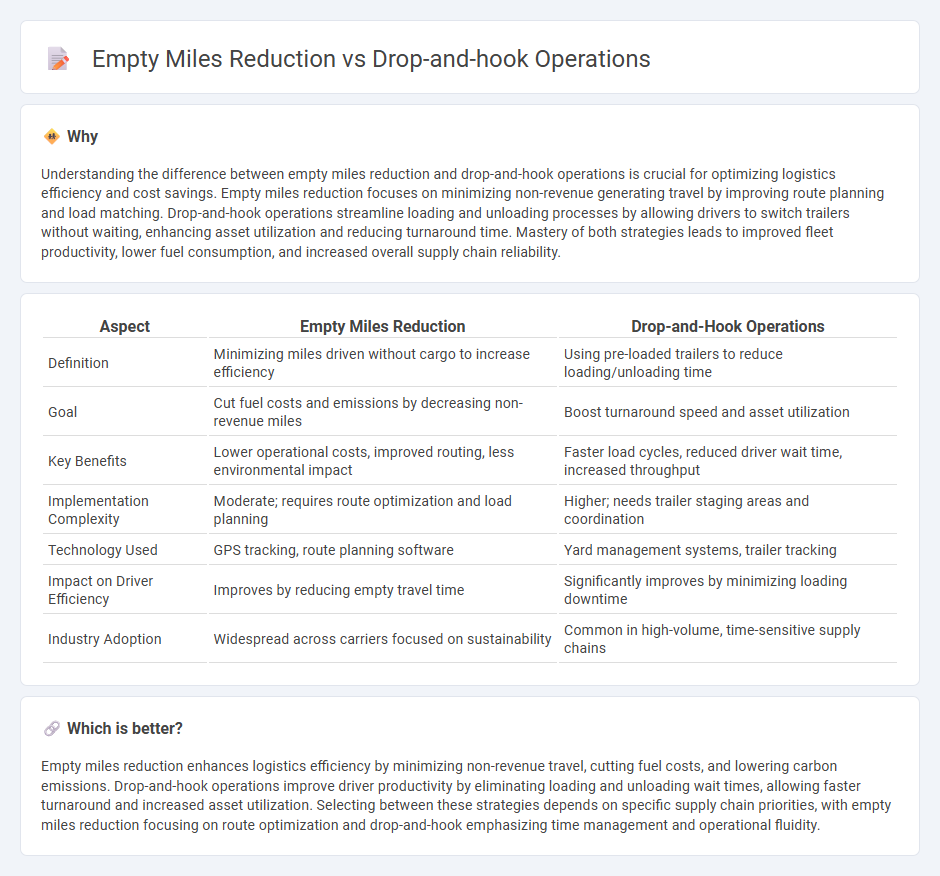

Understanding the difference between empty miles reduction and drop-and-hook operations is crucial for optimizing logistics efficiency and cost savings. Empty miles reduction focuses on minimizing non-revenue generating travel by improving route planning and load matching. Drop-and-hook operations streamline loading and unloading processes by allowing drivers to switch trailers without waiting, enhancing asset utilization and reducing turnaround time. Mastery of both strategies leads to improved fleet productivity, lower fuel consumption, and increased overall supply chain reliability.

Comparison Table

| Aspect | Empty Miles Reduction | Drop-and-Hook Operations |

|---|---|---|

| Definition | Minimizing miles driven without cargo to increase efficiency | Using pre-loaded trailers to reduce loading/unloading time |

| Goal | Cut fuel costs and emissions by decreasing non-revenue miles | Boost turnaround speed and asset utilization |

| Key Benefits | Lower operational costs, improved routing, less environmental impact | Faster load cycles, reduced driver wait time, increased throughput |

| Implementation Complexity | Moderate; requires route optimization and load planning | Higher; needs trailer staging areas and coordination |

| Technology Used | GPS tracking, route planning software | Yard management systems, trailer tracking |

| Impact on Driver Efficiency | Improves by reducing empty travel time | Significantly improves by minimizing loading downtime |

| Industry Adoption | Widespread across carriers focused on sustainability | Common in high-volume, time-sensitive supply chains |

Which is better?

Empty miles reduction enhances logistics efficiency by minimizing non-revenue travel, cutting fuel costs, and lowering carbon emissions. Drop-and-hook operations improve driver productivity by eliminating loading and unloading wait times, allowing faster turnaround and increased asset utilization. Selecting between these strategies depends on specific supply chain priorities, with empty miles reduction focusing on route optimization and drop-and-hook emphasizing time management and operational fluidity.

Connection

Empty miles reduction directly enhances the efficiency of drop-and-hook operations by minimizing non-revenue generating travel and maximizing load opportunities. Drop-and-hook logistics streamline freight handling by allowing drivers to leave an empty trailer at a location and immediately pick up a full one, reducing idle time and increasing asset utilization. This synergy lowers transportation costs and boosts overall supply chain productivity.

Key Terms

**Drop-and-Hook Operations:**

Drop-and-hook operations streamline freight logistics by allowing drivers to quickly swap trailers without waiting for loading or unloading, significantly boosting fleet efficiency. This method reduces detention times and maximizes driver productivity, providing a strategic advantage over conventional freight handling. Explore how drop-and-hook operations can transform your supply chain efficiency and driver utilization.

Trailer Pools

Drop-and-hook operations streamline freight logistics by allowing tractors to quickly switch trailers without waiting for loading or unloading, significantly enhancing fleet productivity. Trailer pools reduce empty miles by strategically positioning trailers where demand is highest, minimizing non-revenue travel and increasing asset utilization. Explore how integrating drop-and-hook strategies with trailer pools can optimize supply chain efficiency and reduce operational costs.

Turnaround Time

Drop-and-hook operations streamline logistics by enabling drivers to leave loaded trailers and pick up preloaded ones, significantly minimizing idle time during deliveries and reducing turnaround time. Empty miles reduction further accelerates turnaround by cutting unnecessary travel without cargo, optimizing route efficiency and fuel consumption. Discover more about how these strategies enhance supply chain performance and operational efficiency.

Source and External Links

What is Drop and Hook Trucking? - FCCR.co - Drop and hook trucking is a method where drivers avoid unloading/loading by dropping a full trailer and hooking up a pre-loaded one at the same facility, increasing efficiency and reducing transportation costs.

What Is Drop and Hook Freight in Logistics? - Prime, Inc. - Drop and hook freight eliminates wait times by letting drivers swap trailers with pre-loaded containers, so drivers do not handle materials and save significant time.

Why carriers, shippers use drop and hook in good times and bad - Drop and hook is widely used for its efficiency in reducing dwell time by dropping off one trailer and attaching a pre-loaded one, favored by carriers and shippers alike.

dowidth.com

dowidth.com