Collaborative logistics emphasizes partnerships and shared resources among companies to optimize supply chain efficiency and reduce costs, while lean logistics focuses on minimizing waste and streamlining processes within a single organization to enhance operational performance. Both strategies aim to improve delivery speed and customer satisfaction but differ in scope and approach. Explore how integrating collaborative and lean logistics can transform your supply chain management.

Why it is important

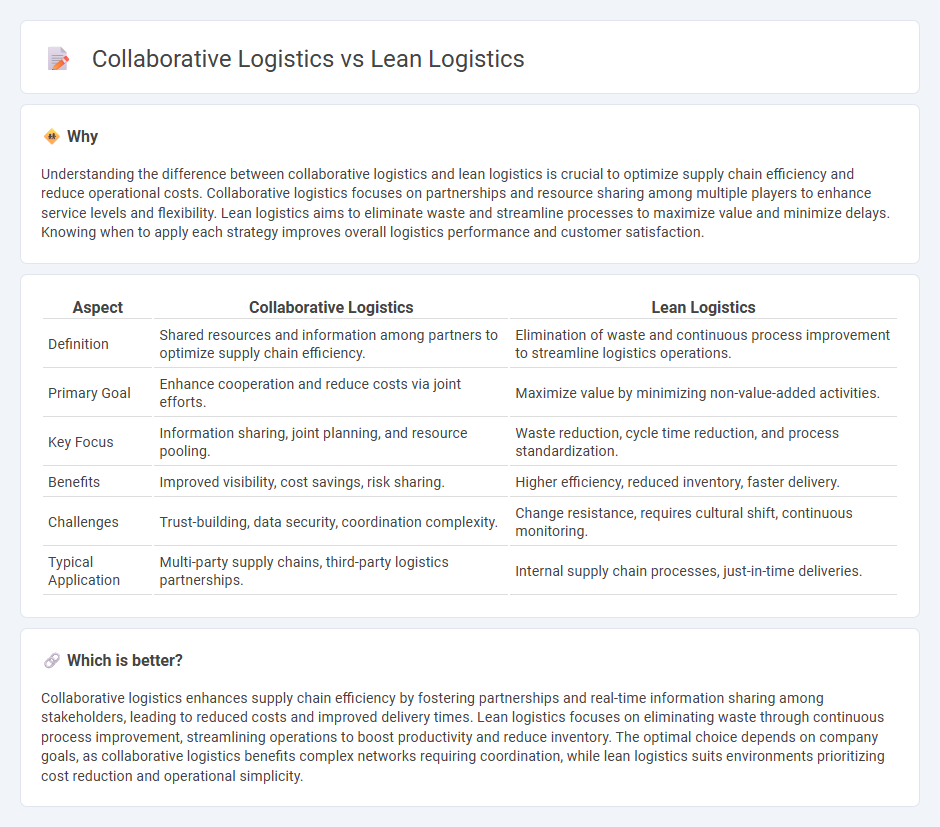

Understanding the difference between collaborative logistics and lean logistics is crucial to optimize supply chain efficiency and reduce operational costs. Collaborative logistics focuses on partnerships and resource sharing among multiple players to enhance service levels and flexibility. Lean logistics aims to eliminate waste and streamline processes to maximize value and minimize delays. Knowing when to apply each strategy improves overall logistics performance and customer satisfaction.

Comparison Table

| Aspect | Collaborative Logistics | Lean Logistics |

|---|---|---|

| Definition | Shared resources and information among partners to optimize supply chain efficiency. | Elimination of waste and continuous process improvement to streamline logistics operations. |

| Primary Goal | Enhance cooperation and reduce costs via joint efforts. | Maximize value by minimizing non-value-added activities. |

| Key Focus | Information sharing, joint planning, and resource pooling. | Waste reduction, cycle time reduction, and process standardization. |

| Benefits | Improved visibility, cost savings, risk sharing. | Higher efficiency, reduced inventory, faster delivery. |

| Challenges | Trust-building, data security, coordination complexity. | Change resistance, requires cultural shift, continuous monitoring. |

| Typical Application | Multi-party supply chains, third-party logistics partnerships. | Internal supply chain processes, just-in-time deliveries. |

Which is better?

Collaborative logistics enhances supply chain efficiency by fostering partnerships and real-time information sharing among stakeholders, leading to reduced costs and improved delivery times. Lean logistics focuses on eliminating waste through continuous process improvement, streamlining operations to boost productivity and reduce inventory. The optimal choice depends on company goals, as collaborative logistics benefits complex networks requiring coordination, while lean logistics suits environments prioritizing cost reduction and operational simplicity.

Connection

Collaborative logistics enhances lean logistics by promoting shared resources, information, and processes among supply chain partners to reduce waste and improve efficiency. Lean logistics focuses on minimizing non-value-added activities, while collaborative logistics enables real-time coordination and joint problem-solving that support lean principles. Together, they optimize inventory levels, transportation costs, and delivery times through synchronized efforts across multiple stakeholders.

Key Terms

**Lean Logistics:**

Lean logistics streamlines supply chain processes by minimizing waste, reducing inventory costs, and enhancing overall efficiency through Just-In-Time (JIT) delivery and continuous improvement methodologies. It emphasizes value creation by eliminating non-value-added activities, optimizing transportation routes, and improving warehouse management to accelerate product flow. Explore more to understand how lean logistics can transform operational performance and reduce costs effectively.

Waste Reduction

Lean logistics emphasizes minimizing waste by streamlining processes, eliminating non-value-added activities, and improving inventory management to reduce excess stock and lead times. Collaborative logistics leverages partnerships and shared resources among multiple stakeholders to optimize routes, consolidate shipments, and reduce overall carbon footprint and operational costs. Explore how integrating lean and collaborative strategies can enhance waste reduction in supply chain management.

Just-in-Time (JIT)

Lean logistics emphasizes minimizing waste and optimizing inventory flow to support Just-in-Time (JIT) production, reducing holding costs and enhancing efficiency. Collaborative logistics, on the other hand, leverages partnerships and information sharing across the supply chain to synchronize deliveries and resources, facilitating precise JIT operations. Discover more about how these approaches transform supply chain management for JIT success.

Source and External Links

Lean Logistics: Streamlining Your Supply Chain for Efficiency and ... - Lean logistics focuses on identifying and eliminating waste in the supply chain to improve efficiency, reduce costs, and ensure a seamless flow of goods by removing unnecessary processes and activities that do not add value.

Lean logistics: lean into efficiency - Lean logistics is a management philosophy that aims to reduce logistics costs by identifying and cutting out non-value-adding activities, thereby shortening order cycle times and increasing overall supply chain efficiency.

Lean Logistics: Improving Efficiency in the Supply Chain - Lean logistics optimizes supply chain efficiency by eliminating wasteful activities at every stage, maximizing customer value, and using the minimum necessary resources, inspired by the principles of Lean Thinking.

dowidth.com

dowidth.com