Drop shipping allows retailers to sell products without holding inventory by directly shipping from suppliers to customers, reducing warehouse costs and minimizing upfront investment. Just-in-time (JIT) delivery focuses on receiving goods exactly when needed in the production process, optimizing inventory levels and reducing storage expenses. Explore the key differences and benefits of drop shipping versus JIT delivery to enhance your supply chain strategy.

Why it is important

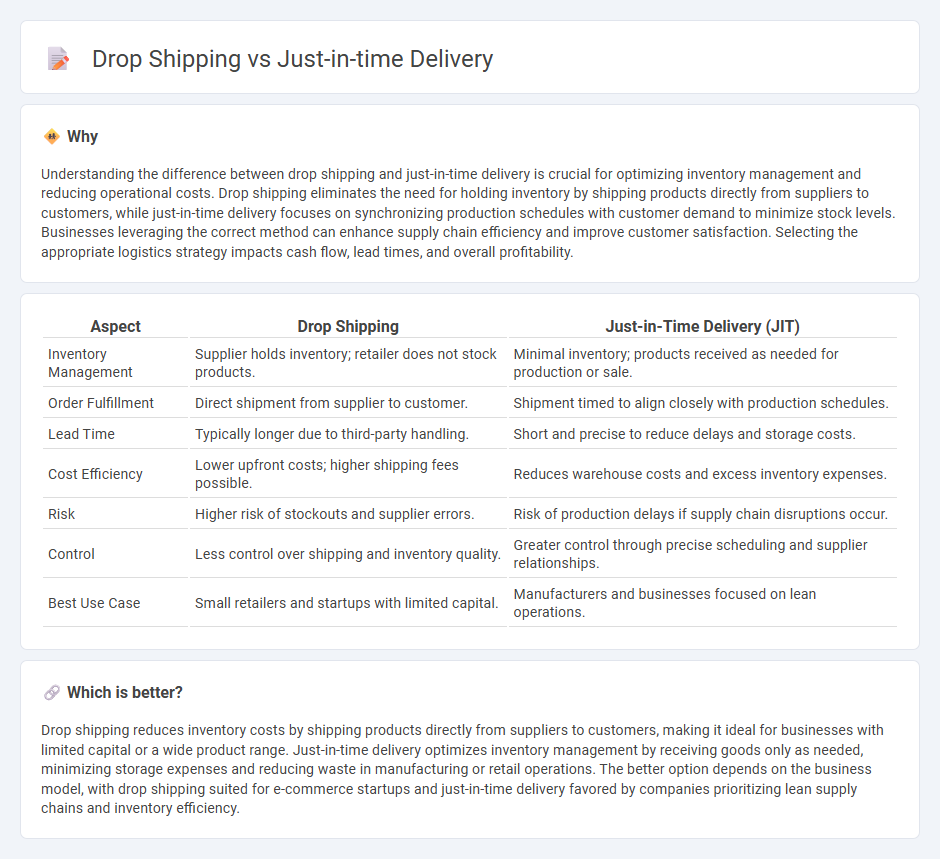

Understanding the difference between drop shipping and just-in-time delivery is crucial for optimizing inventory management and reducing operational costs. Drop shipping eliminates the need for holding inventory by shipping products directly from suppliers to customers, while just-in-time delivery focuses on synchronizing production schedules with customer demand to minimize stock levels. Businesses leveraging the correct method can enhance supply chain efficiency and improve customer satisfaction. Selecting the appropriate logistics strategy impacts cash flow, lead times, and overall profitability.

Comparison Table

| Aspect | Drop Shipping | Just-in-Time Delivery (JIT) |

|---|---|---|

| Inventory Management | Supplier holds inventory; retailer does not stock products. | Minimal inventory; products received as needed for production or sale. |

| Order Fulfillment | Direct shipment from supplier to customer. | Shipment timed to align closely with production schedules. |

| Lead Time | Typically longer due to third-party handling. | Short and precise to reduce delays and storage costs. |

| Cost Efficiency | Lower upfront costs; higher shipping fees possible. | Reduces warehouse costs and excess inventory expenses. |

| Risk | Higher risk of stockouts and supplier errors. | Risk of production delays if supply chain disruptions occur. |

| Control | Less control over shipping and inventory quality. | Greater control through precise scheduling and supplier relationships. |

| Best Use Case | Small retailers and startups with limited capital. | Manufacturers and businesses focused on lean operations. |

Which is better?

Drop shipping reduces inventory costs by shipping products directly from suppliers to customers, making it ideal for businesses with limited capital or a wide product range. Just-in-time delivery optimizes inventory management by receiving goods only as needed, minimizing storage expenses and reducing waste in manufacturing or retail operations. The better option depends on the business model, with drop shipping suited for e-commerce startups and just-in-time delivery favored by companies prioritizing lean supply chains and inventory efficiency.

Connection

Drop shipping and just-in-time delivery both aim to minimize inventory holding costs by synchronizing product arrival with customer demand, reducing warehousing needs and capital investment. Drop shipping relies on suppliers shipping products directly to customers, which complements just-in-time strategies by enabling faster, flexible fulfillment without maintaining stock. This synergy enhances supply chain efficiency and responsiveness, driving cost savings and improving customer satisfaction.

Key Terms

Inventory Management

Just-in-time delivery minimizes inventory holding by receiving goods only as they are needed in the production process, reducing storage costs and increasing cash flow efficiency. Drop shipping eliminates inventory by transferring customer orders directly to suppliers, enabling retailers to sell products without owning stock. Explore the detailed benefits and challenges of both inventory management strategies to optimize your supply chain.

Lead Time

Just-in-time delivery reduces lead time by synchronizing inventory arrival directly with production schedules, minimizing storage costs and ensuring faster order fulfillment. Drop shipping typically involves longer lead times since products are shipped from suppliers directly to customers, often resulting in variable transit durations and limited control over delivery speed. Explore detailed comparisons to understand which model better suits your supply chain efficiency needs.

Fulfillment Model

Just-in-time delivery minimizes inventory holding by synchronizing product arrival with customer demand, reducing storage costs and enhancing supply chain efficiency. Drop shipping eliminates the need for physical inventory by having suppliers ship directly to customers, offering scalability but potentially longer delivery times. Explore more to understand which fulfillment model best suits your business needs and operational goals.

Source and External Links

Just in Time Delivery: What is it, and How Does it Affect Supply - Just-in-Time delivery involves producing and delivering goods to meet immediate demand, minimizing inventory and enabling timely customer satisfaction.

Just In Time (JIT) Delivery: The Ultimate Guide - JIT delivery aims to increase efficiency by reducing inventory, producing and delivering products only when needed, thereby minimizing inventory costs.

What is JIT Delivery? - JIT delivery is a logistics strategy focused on minimizing inventory storage costs and improving efficiency by delivering goods precisely when needed.

dowidth.com

dowidth.com