Pick and pack involves selecting individual items from inventory and packing them immediately for shipment, enhancing order accuracy and reducing handling time. Batch picking groups multiple orders together, allowing workers to pick items for several orders simultaneously, improving efficiency in high-volume environments. Explore the benefits and best practices of each method to optimize your logistics operations.

Why it is important

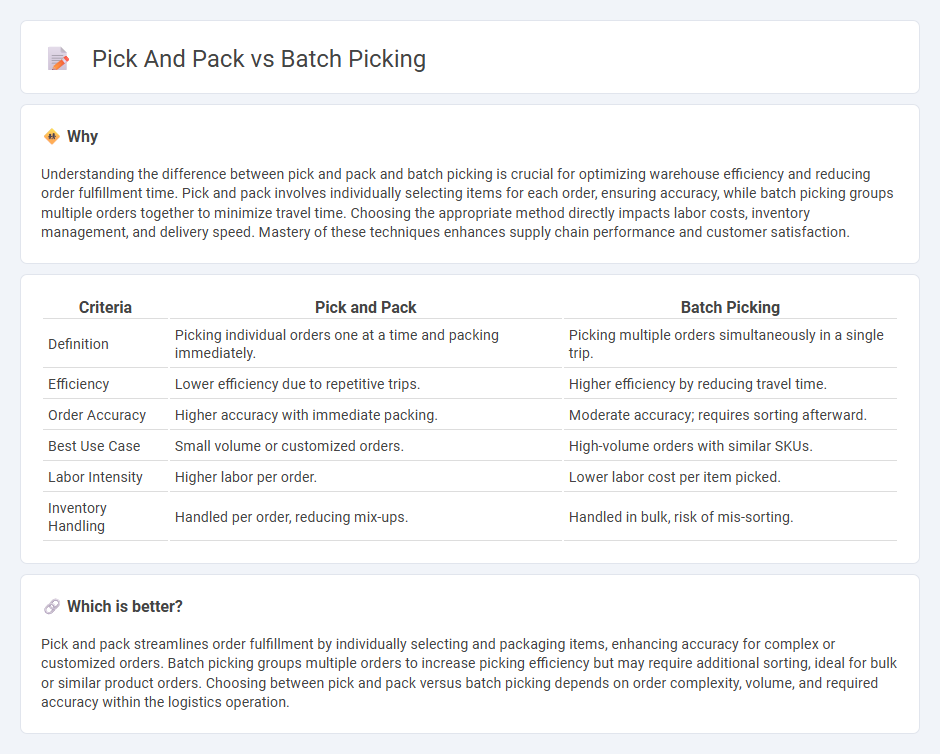

Understanding the difference between pick and pack and batch picking is crucial for optimizing warehouse efficiency and reducing order fulfillment time. Pick and pack involves individually selecting items for each order, ensuring accuracy, while batch picking groups multiple orders together to minimize travel time. Choosing the appropriate method directly impacts labor costs, inventory management, and delivery speed. Mastery of these techniques enhances supply chain performance and customer satisfaction.

Comparison Table

| Criteria | Pick and Pack | Batch Picking |

|---|---|---|

| Definition | Picking individual orders one at a time and packing immediately. | Picking multiple orders simultaneously in a single trip. |

| Efficiency | Lower efficiency due to repetitive trips. | Higher efficiency by reducing travel time. |

| Order Accuracy | Higher accuracy with immediate packing. | Moderate accuracy; requires sorting afterward. |

| Best Use Case | Small volume or customized orders. | High-volume orders with similar SKUs. |

| Labor Intensity | Higher labor per order. | Lower labor cost per item picked. |

| Inventory Handling | Handled per order, reducing mix-ups. | Handled in bulk, risk of mis-sorting. |

Which is better?

Pick and pack streamlines order fulfillment by individually selecting and packaging items, enhancing accuracy for complex or customized orders. Batch picking groups multiple orders to increase picking efficiency but may require additional sorting, ideal for bulk or similar product orders. Choosing between pick and pack versus batch picking depends on order complexity, volume, and required accuracy within the logistics operation.

Connection

Pick and pack and batch picking are interconnected logistics processes designed to enhance order fulfillment efficiency by reducing handling time and increasing accuracy. Batch picking consolidates multiple orders into a single picking session based on product similarity, which streamlines the subsequent pick and pack stage where items are sorted, packed, and prepared for shipment. This integration optimizes warehouse productivity and minimizes operational costs by leveraging coordinated picking strategies.

Key Terms

Order Consolidation

Batch picking groups multiple orders to minimize travel time and increase picking efficiency, streamlining order consolidation by collecting items in bulk before sorting. Pick and pack separates picking and packing stages, allowing precise order consolidation by assembling products individually after picking. Explore more to optimize your warehouse operations with the best order consolidation strategies.

Fulfillment Efficiency

Batch picking enhances fulfillment efficiency by consolidating multiple orders into a single picking session, reducing travel time and increasing worker productivity. Pick and pack optimizes order accuracy and packaging speed by separating the picking process from packing stages, aligning well with complex or customized orders. Explore deeper insights on how these methods can transform your fulfillment operations.

Picking Method

Batch picking consolidates multiple orders into a single picking route, enhancing efficiency by reducing travel time and increasing throughput in high-volume warehouses. Pick and pack involves picking items for one order at a time and packaging them immediately, ideal for customized orders with varied SKUs. Explore how choosing the right picking method can optimize your warehouse operations and improve fulfillment speed.

Source and External Links

Batch Picking 101: Benefits, Examples, and Best Practices - Batch picking is a method where a picker gathers multiple orders simultaneously by grouping orders with shared products and proximity in the warehouse, then picking all items in a batch before sorting them into individual orders for shipment, which improves efficiency by reducing trips around the warehouse.

Batch picking -- Odoo 18.0 documentation - Batch picking allows a single picker to handle multiple orders in one go, reducing travel time in the warehouse, best suited for businesses with few fast-moving products, but requires sorting products into orders at an output location after picking.

Unlocking Batch Picking: 7 Best Practices & Pros and Cons - Batch picking is a process in which a worker collects items for several orders simultaneously guided by a picking list and then sorts them later, increasing efficiency especially during high demand periods by cutting down the number of separate picking trips needed.

dowidth.com

dowidth.com