Freight visibility enhances supply chain transparency by providing real-time data on shipment status, enabling companies to track goods accurately and anticipate potential delays. Demand forecasting leverages historical data and predictive analytics to estimate future customer demand, helping optimize inventory and reduce costs. Explore how integrating freight visibility with demand forecasting can revolutionize logistics efficiency and responsiveness.

Why it is important

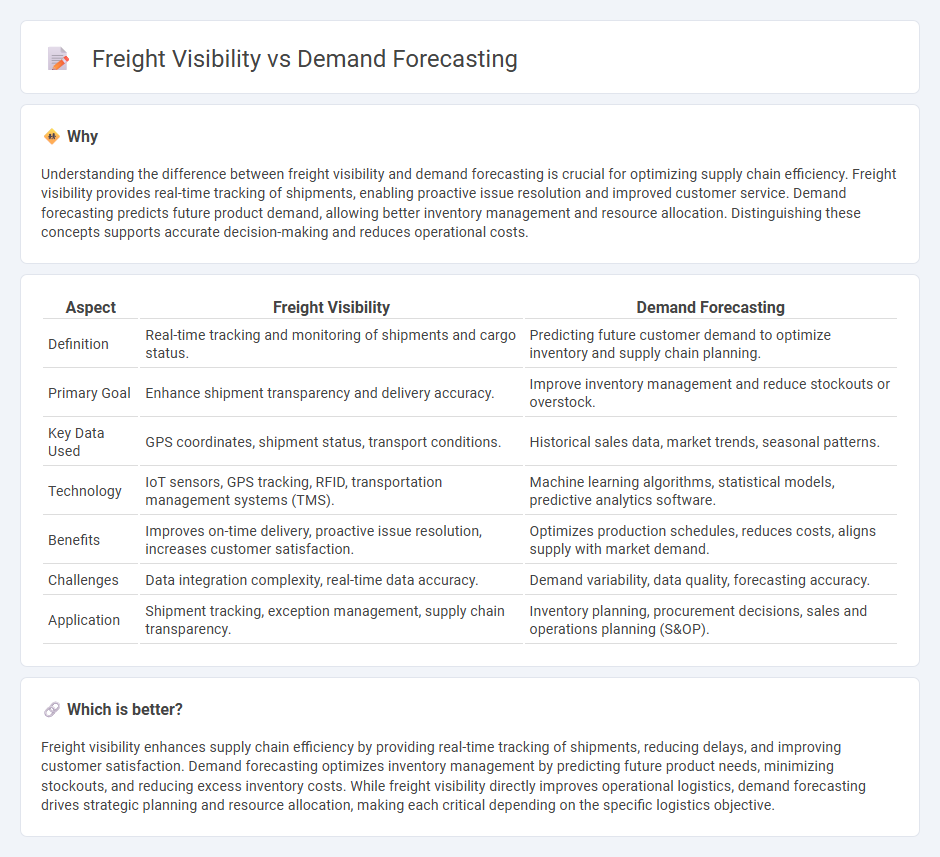

Understanding the difference between freight visibility and demand forecasting is crucial for optimizing supply chain efficiency. Freight visibility provides real-time tracking of shipments, enabling proactive issue resolution and improved customer service. Demand forecasting predicts future product demand, allowing better inventory management and resource allocation. Distinguishing these concepts supports accurate decision-making and reduces operational costs.

Comparison Table

| Aspect | Freight Visibility | Demand Forecasting |

|---|---|---|

| Definition | Real-time tracking and monitoring of shipments and cargo status. | Predicting future customer demand to optimize inventory and supply chain planning. |

| Primary Goal | Enhance shipment transparency and delivery accuracy. | Improve inventory management and reduce stockouts or overstock. |

| Key Data Used | GPS coordinates, shipment status, transport conditions. | Historical sales data, market trends, seasonal patterns. |

| Technology | IoT sensors, GPS tracking, RFID, transportation management systems (TMS). | Machine learning algorithms, statistical models, predictive analytics software. |

| Benefits | Improves on-time delivery, proactive issue resolution, increases customer satisfaction. | Optimizes production schedules, reduces costs, aligns supply with market demand. |

| Challenges | Data integration complexity, real-time data accuracy. | Demand variability, data quality, forecasting accuracy. |

| Application | Shipment tracking, exception management, supply chain transparency. | Inventory planning, procurement decisions, sales and operations planning (S&OP). |

Which is better?

Freight visibility enhances supply chain efficiency by providing real-time tracking of shipments, reducing delays, and improving customer satisfaction. Demand forecasting optimizes inventory management by predicting future product needs, minimizing stockouts, and reducing excess inventory costs. While freight visibility directly improves operational logistics, demand forecasting drives strategic planning and resource allocation, making each critical depending on the specific logistics objective.

Connection

Freight visibility enhances demand forecasting accuracy by providing real-time data on shipment locations, transit times, and delivery statuses, enabling more precise predictions of inventory needs. Advanced tracking systems integrate with demand forecasting algorithms to adjust supply chain operations dynamically based on actual freight movement patterns. This connectivity reduces stockouts, optimizes warehouse management, and improves overall logistics efficiency through data-driven decision-making.

Key Terms

Demand Forecasting:

Demand forecasting uses historical sales data, market trends, and statistical models to predict future customer demand, enabling businesses to optimize inventory and production planning. Accurate demand forecasting reduces stockouts, minimizes excess inventory, and enhances supply chain efficiency by aligning resources with anticipated market needs. Discover how advanced demand forecasting tools can transform your operational strategy today.

Historical Data Analysis

Demand forecasting leverages historical data analysis to predict future customer demand patterns, optimizing inventory management and supply chain planning. Freight visibility uses historical shipment data to track and monitor goods in transit, enhancing logistics efficiency and reducing delivery uncertainties. Explore how integrating historical data analysis can improve both demand forecasting and freight visibility accuracy.

Predictive Analytics

Demand forecasting leverages predictive analytics to estimate future customer requirements by analyzing historical sales data, market trends, and seasonal patterns, enhancing inventory management and reducing stockouts. Freight visibility uses predictive analytics to track shipment status in real-time, forecast delivery times, and predict potential disruptions, improving supply chain transparency and operational efficiency. Explore how integrating predictive analytics in these domains can revolutionize your logistics strategy.

Source and External Links

Demand forecasting - Wikipedia - Demand forecasting, also known as demand planning and sales forecasting, is the process of predicting future consumer or business demand for goods and services using qualitative methods based on expert opinions and quantitative methods based on available data and analytics, helping optimize supply chain and business decisions.

Demand Forecasting Guide: Definition, Types, Methods, Examples - Demand forecasting estimates future product demand to guide production and inventory, using methods like trend projection, market research, and sales force composite to create accurate forecasts based on historical data and customer insights.

Types of Demand Forecast - GeeksforGeeks - Demand forecasting involves predictive analysis of past data to anticipate future customer demand, with various approaches including active demand forecasting, external macro forecasting, Delphi method, econometrics, and micro-level forecasting, aiding in inventory and production optimization.

dowidth.com

dowidth.com