Collaborative logistics focuses on multiple organizations sharing resources and information to improve efficiency and reduce costs, often leveraging technology platforms for real-time coordination. Integrated logistics, on the other hand, involves the seamless management of the entire supply chain within a single company, ensuring synchronization of procurement, warehousing, transportation, and distribution activities. Explore further to understand how these approaches optimize supply chain performance and drive competitive advantage.

Why it is important

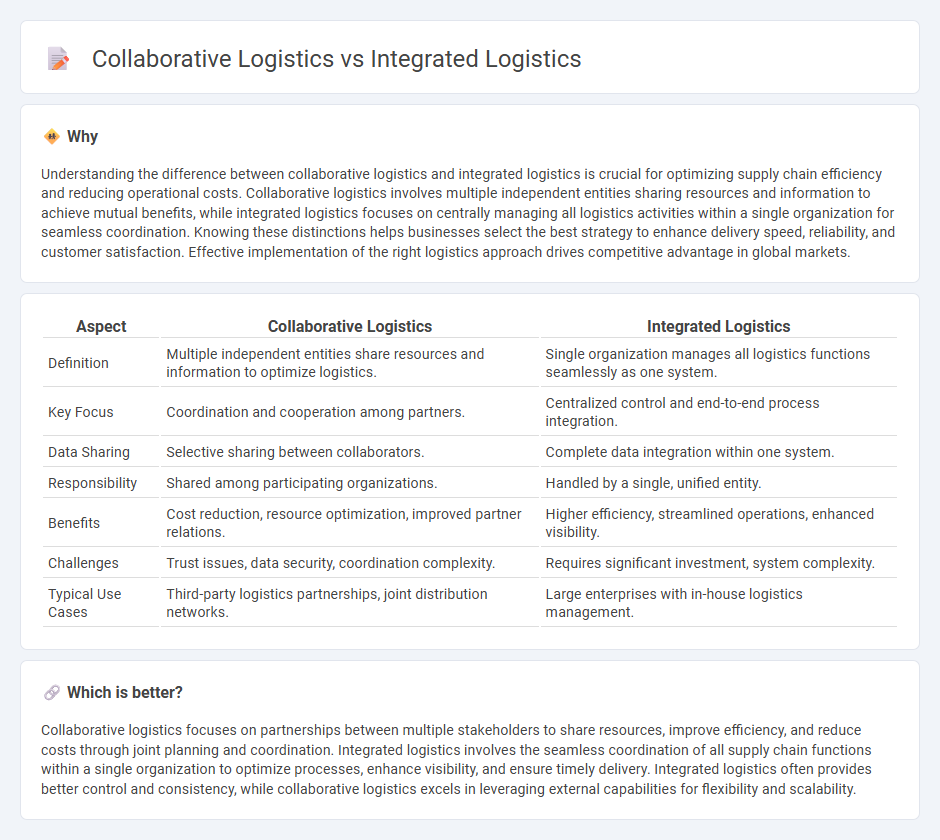

Understanding the difference between collaborative logistics and integrated logistics is crucial for optimizing supply chain efficiency and reducing operational costs. Collaborative logistics involves multiple independent entities sharing resources and information to achieve mutual benefits, while integrated logistics focuses on centrally managing all logistics activities within a single organization for seamless coordination. Knowing these distinctions helps businesses select the best strategy to enhance delivery speed, reliability, and customer satisfaction. Effective implementation of the right logistics approach drives competitive advantage in global markets.

Comparison Table

| Aspect | Collaborative Logistics | Integrated Logistics |

|---|---|---|

| Definition | Multiple independent entities share resources and information to optimize logistics. | Single organization manages all logistics functions seamlessly as one system. |

| Key Focus | Coordination and cooperation among partners. | Centralized control and end-to-end process integration. |

| Data Sharing | Selective sharing between collaborators. | Complete data integration within one system. |

| Responsibility | Shared among participating organizations. | Handled by a single, unified entity. |

| Benefits | Cost reduction, resource optimization, improved partner relations. | Higher efficiency, streamlined operations, enhanced visibility. |

| Challenges | Trust issues, data security, coordination complexity. | Requires significant investment, system complexity. |

| Typical Use Cases | Third-party logistics partnerships, joint distribution networks. | Large enterprises with in-house logistics management. |

Which is better?

Collaborative logistics focuses on partnerships between multiple stakeholders to share resources, improve efficiency, and reduce costs through joint planning and coordination. Integrated logistics involves the seamless coordination of all supply chain functions within a single organization to optimize processes, enhance visibility, and ensure timely delivery. Integrated logistics often provides better control and consistency, while collaborative logistics excels in leveraging external capabilities for flexibility and scalability.

Connection

Collaborative logistics enhances supply chain efficiency by enabling multiple stakeholders to share resources, information, and transportation networks, which directly supports integrated logistics systems that unify various logistics functions under a coordinated management approach. Integrated logistics relies on collaborative practices to synchronize procurement, inventory management, and distribution activities, reducing redundancies and lowering operational costs. The synergy between collaborative logistics and integrated logistics drives improved visibility, real-time communication, and agile decision-making across the entire supply chain.

Key Terms

**Integrated Logistics:**

Integrated logistics streamlines supply chain operations by unifying transportation, warehousing, inventory management, and information systems into a single cohesive framework to enhance efficiency and reduce costs. This approach facilitates real-time data sharing, seamless communication, and synchronized processes across all logistics functions, leading to improved delivery reliability and customer satisfaction. Discover more on how integrated logistics transforms supply chain management for businesses seeking competitive advantages.

Supply Chain Integration

Integrated logistics centralizes supply chain functions to enhance efficiency by unifying transportation, warehousing, and inventory management under a single management system. Collaborative logistics emphasizes partnerships among multiple supply chain stakeholders to share resources and information, boosting responsiveness and flexibility. Explore deeper insights to understand how these logistics strategies transform supply chain integration.

Process Optimization

Integrated logistics centralizes supply chain activities to streamline transportation, warehousing, and inventory management, leading to significant cost reductions and enhanced operational efficiency. Collaborative logistics emphasizes partnership and information-sharing among multiple stakeholders to synchronize processes and improve overall supply chain visibility and responsiveness. Explore deeper insights into how these logistics strategies drive process optimization and business performance.

Source and External Links

Integrated Logistics - time:matters - Integrated logistics involves coordinating all supply chain entities, including data, processes, and people, to ensure smooth shipment transport across supply, production, marketing, and delivery stages.

Integrated Logistics Transformation - Turvo - Integrated logistics is a holistic approach that breaks down silos and coordinates all supply chain activities to optimize efficiency, reduce costs, and improve customer service.

Integrated Logistics - SafetyCulture - Integrated logistics combines transportation, warehousing, inventory management, and order processing to create a unified system that enhances speed, agility, cost efficiency, and customer service.

dowidth.com

dowidth.com