Cold chain management ensures the temperature-controlled supply chain for perishable goods, maintaining product integrity from production to delivery through specialized refrigeration and monitoring systems. Order fulfillment encompasses the entire process of receiving, processing, and delivering customer orders efficiently, emphasizing accuracy and speed. Explore the key differences and best practices to optimize your logistics operations effectively.

Why it is important

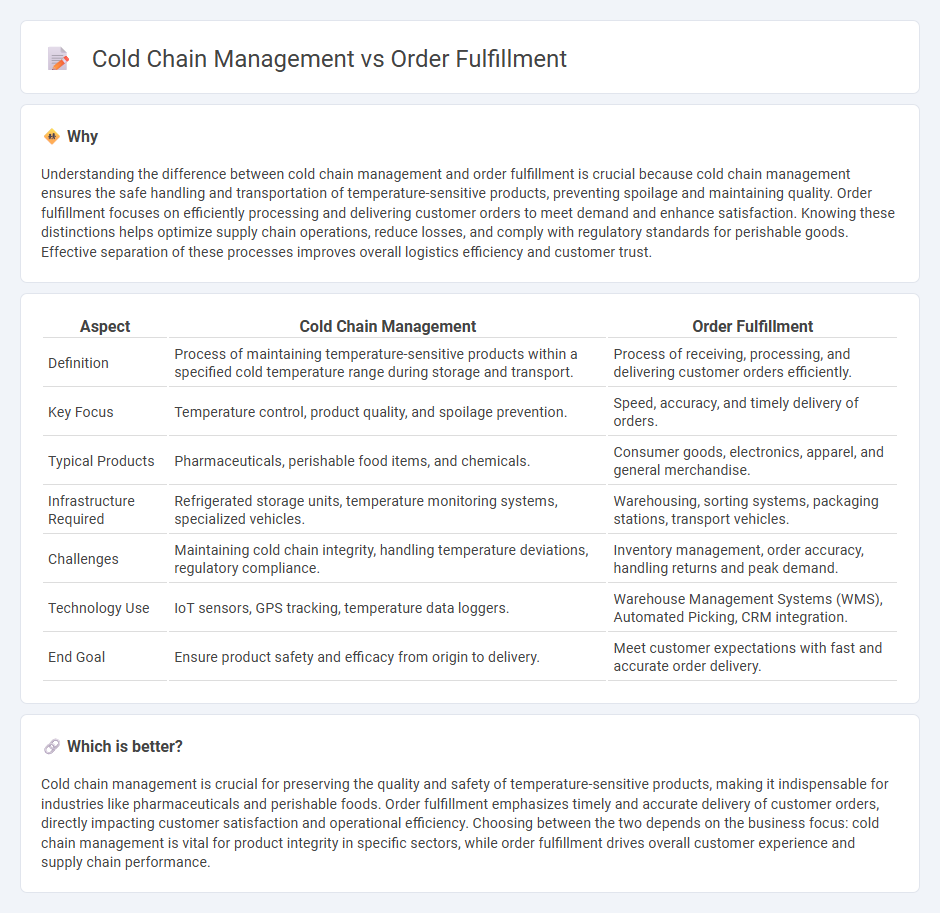

Understanding the difference between cold chain management and order fulfillment is crucial because cold chain management ensures the safe handling and transportation of temperature-sensitive products, preventing spoilage and maintaining quality. Order fulfillment focuses on efficiently processing and delivering customer orders to meet demand and enhance satisfaction. Knowing these distinctions helps optimize supply chain operations, reduce losses, and comply with regulatory standards for perishable goods. Effective separation of these processes improves overall logistics efficiency and customer trust.

Comparison Table

| Aspect | Cold Chain Management | Order Fulfillment |

|---|---|---|

| Definition | Process of maintaining temperature-sensitive products within a specified cold temperature range during storage and transport. | Process of receiving, processing, and delivering customer orders efficiently. |

| Key Focus | Temperature control, product quality, and spoilage prevention. | Speed, accuracy, and timely delivery of orders. |

| Typical Products | Pharmaceuticals, perishable food items, and chemicals. | Consumer goods, electronics, apparel, and general merchandise. |

| Infrastructure Required | Refrigerated storage units, temperature monitoring systems, specialized vehicles. | Warehousing, sorting systems, packaging stations, transport vehicles. |

| Challenges | Maintaining cold chain integrity, handling temperature deviations, regulatory compliance. | Inventory management, order accuracy, handling returns and peak demand. |

| Technology Use | IoT sensors, GPS tracking, temperature data loggers. | Warehouse Management Systems (WMS), Automated Picking, CRM integration. |

| End Goal | Ensure product safety and efficacy from origin to delivery. | Meet customer expectations with fast and accurate order delivery. |

Which is better?

Cold chain management is crucial for preserving the quality and safety of temperature-sensitive products, making it indispensable for industries like pharmaceuticals and perishable foods. Order fulfillment emphasizes timely and accurate delivery of customer orders, directly impacting customer satisfaction and operational efficiency. Choosing between the two depends on the business focus: cold chain management is vital for product integrity in specific sectors, while order fulfillment drives overall customer experience and supply chain performance.

Connection

Cold chain management ensures temperature-sensitive products maintain optimal conditions throughout storage and transportation, directly impacting order fulfillment accuracy and product quality. Efficient cold chain logistics reduce spoilage risks and delivery delays, enhancing customer satisfaction and supply chain reliability. Seamless integration of cold chain protocols with order fulfillment systems supports timely and compliant delivery of perishable goods.

Key Terms

Order Fulfillment:

Order fulfillment encompasses the entire process of receiving, processing, and delivering customer orders efficiently, aiming to maximize accuracy and speed. Key components include inventory management, picking and packing, shipping logistics, and real-time tracking to ensure timely delivery. Discover more about how optimizing order fulfillment can enhance customer satisfaction and operational efficiency.

Inventory Management

Order fulfillment centers on efficiently processing and delivering customer orders while maintaining accurate inventory levels to prevent stockouts and overstocking. Cold chain management emphasizes precise temperature-controlled inventory management to ensure product safety and quality, particularly for perishable goods like pharmaceuticals and fresh foods. Explore how integrating advanced inventory tracking systems can optimize both order fulfillment and cold chain processes for better supply chain performance.

Pick and Pack

Order fulfillment and cold chain management both emphasize the pick and pack process, but cold chain management requires specialized temperature-controlled environments during picking and packing to ensure product integrity. Efficient order fulfillment focuses on speed and accuracy, integrating real-time inventory data to optimize pick paths and packing methods. Explore the critical differences and best practices for pick and pack in each field to enhance operational efficiency and product safety.

Source and External Links

Order Fulfillment: Meaning, Process, and How To Optimize - This article provides an overview of the order fulfillment process, including receiving, storage, and order processing.

Order Fulfillment Process: Definition and 7 Key Steps - Indeed explains the order fulfillment process through seven key steps, from receiving inventory to shipping products.

What Is Order Fulfillment? Improve Your Process & Strategy - Shopify discusses the order fulfillment process, including inventory management and delivery, and provides strategies for improvement.

dowidth.com

dowidth.com