Supply chain control towers offer centralized visibility and real-time analytics across multiple logistics functions, enhancing decision-making and operational efficiency beyond the scope of traditional Warehouse Management Systems (WMS). While WMS focuses on optimizing warehouse operations such as inventory tracking, order fulfillment, and labor management, control towers integrate end-to-end supply chain processes including transportation, procurement, and demand forecasting. Explore deeper insights to understand how combining these technologies can transform your logistics strategy.

Why it is important

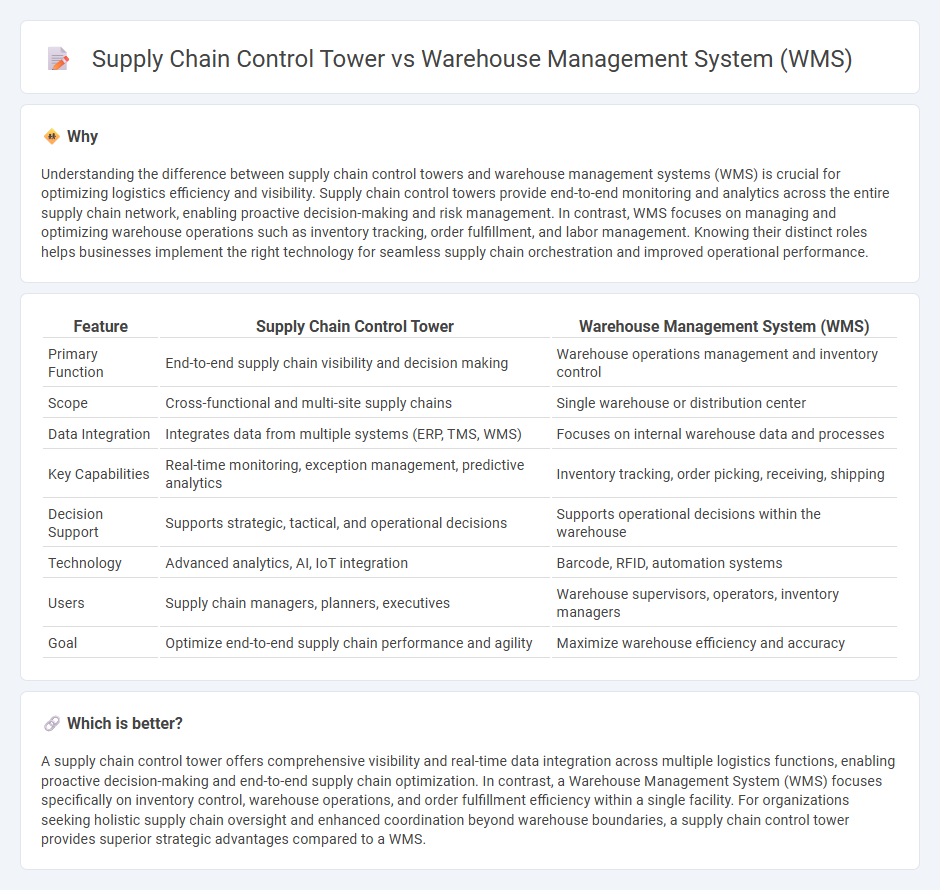

Understanding the difference between supply chain control towers and warehouse management systems (WMS) is crucial for optimizing logistics efficiency and visibility. Supply chain control towers provide end-to-end monitoring and analytics across the entire supply chain network, enabling proactive decision-making and risk management. In contrast, WMS focuses on managing and optimizing warehouse operations such as inventory tracking, order fulfillment, and labor management. Knowing their distinct roles helps businesses implement the right technology for seamless supply chain orchestration and improved operational performance.

Comparison Table

| Feature | Supply Chain Control Tower | Warehouse Management System (WMS) |

|---|---|---|

| Primary Function | End-to-end supply chain visibility and decision making | Warehouse operations management and inventory control |

| Scope | Cross-functional and multi-site supply chains | Single warehouse or distribution center |

| Data Integration | Integrates data from multiple systems (ERP, TMS, WMS) | Focuses on internal warehouse data and processes |

| Key Capabilities | Real-time monitoring, exception management, predictive analytics | Inventory tracking, order picking, receiving, shipping |

| Decision Support | Supports strategic, tactical, and operational decisions | Supports operational decisions within the warehouse |

| Technology | Advanced analytics, AI, IoT integration | Barcode, RFID, automation systems |

| Users | Supply chain managers, planners, executives | Warehouse supervisors, operators, inventory managers |

| Goal | Optimize end-to-end supply chain performance and agility | Maximize warehouse efficiency and accuracy |

Which is better?

A supply chain control tower offers comprehensive visibility and real-time data integration across multiple logistics functions, enabling proactive decision-making and end-to-end supply chain optimization. In contrast, a Warehouse Management System (WMS) focuses specifically on inventory control, warehouse operations, and order fulfillment efficiency within a single facility. For organizations seeking holistic supply chain oversight and enhanced coordination beyond warehouse boundaries, a supply chain control tower provides superior strategic advantages compared to a WMS.

Connection

Supply chain control towers integrate data from warehouse management systems (WMS) to provide real-time visibility and centralized monitoring of inventory, order status, and material flows. This connection enables synchronized decision-making by leveraging WMS data for accurate demand forecasting, route optimization, and inventory replenishment. Enhanced collaboration between supply chain control towers and WMS systems leads to improved operational efficiency, reduced lead times, and optimized resource allocation.

Key Terms

Inventory Visibility

Warehouse Management System (WMS) offers granular, real-time inventory tracking within warehouse operations, optimizing stock placement and order fulfillment. Supply Chain Control Tower provides end-to-end inventory visibility across multiple sites and transportation, enabling proactive decision-making and risk management. Discover how integrating WMS with Control Towers enhances comprehensive inventory insights and operational efficiency.

Order Fulfillment

Warehouse Management System (WMS) optimizes order fulfillment by managing inventory, picking, packing, and shipping processes within the warehouse, ensuring accuracy and efficiency on the operational level. Supply Chain Control Tower offers a broader perspective by providing real-time visibility and coordination across multiple warehouses, transportation, and suppliers to streamline end-to-end order fulfillment. Explore how integrating both solutions can maximize order fulfillment performance and supply chain responsiveness.

Real-time Analytics

Warehouse Management Systems (WMS) streamline inventory management and order fulfillment within warehouses using real-time analytics for precise stock tracking and workflow optimization. Supply Chain Control Towers provide a broader view by integrating data across the entire supply chain, enabling real-time visibility, exception management, and predictive insights to enhance decision-making across multiple nodes. Explore how leveraging real-time analytics in both systems can transform operational efficiency and responsiveness in your supply chain.

Source and External Links

What is a WMS? | Warehouse Management System - A Warehouse Management System (WMS) is software that manages all day-to-day warehouse operations, including labor management, pick efficiency, real-time inventory tracking, shipping, order fulfillment, forecasting, and reporting to optimize warehouse workflows and profitability.

What is WMS (Warehouse Management System)? - A WMS is a software solution that provides visibility into inventory and supply chain fulfillment, maximizing labor, space, and equipment utilization while optimizing global supply chain operations and meeting modern omni-channel fulfillment demands.

What is a Warehouse Management System (WMS)? | Manhattan - WMS software supports inventory, order, and labor management, warehouse optimization, and integrates with automation systems to improve efficiency, accuracy, scalability, and reduce costs in warehouse operations.

dowidth.com

dowidth.com