Urban air mobility revolutionizes logistics by enabling rapid, flexible transport of goods through aerial drones and air taxis, reducing ground traffic congestion and delivery times. Warehouse automation optimizes storage and order fulfillment with robotics and AI-driven systems, increasing efficiency and accuracy on the ground. Explore how these innovations reshape supply chain dynamics and operational strategies.

Why it is important

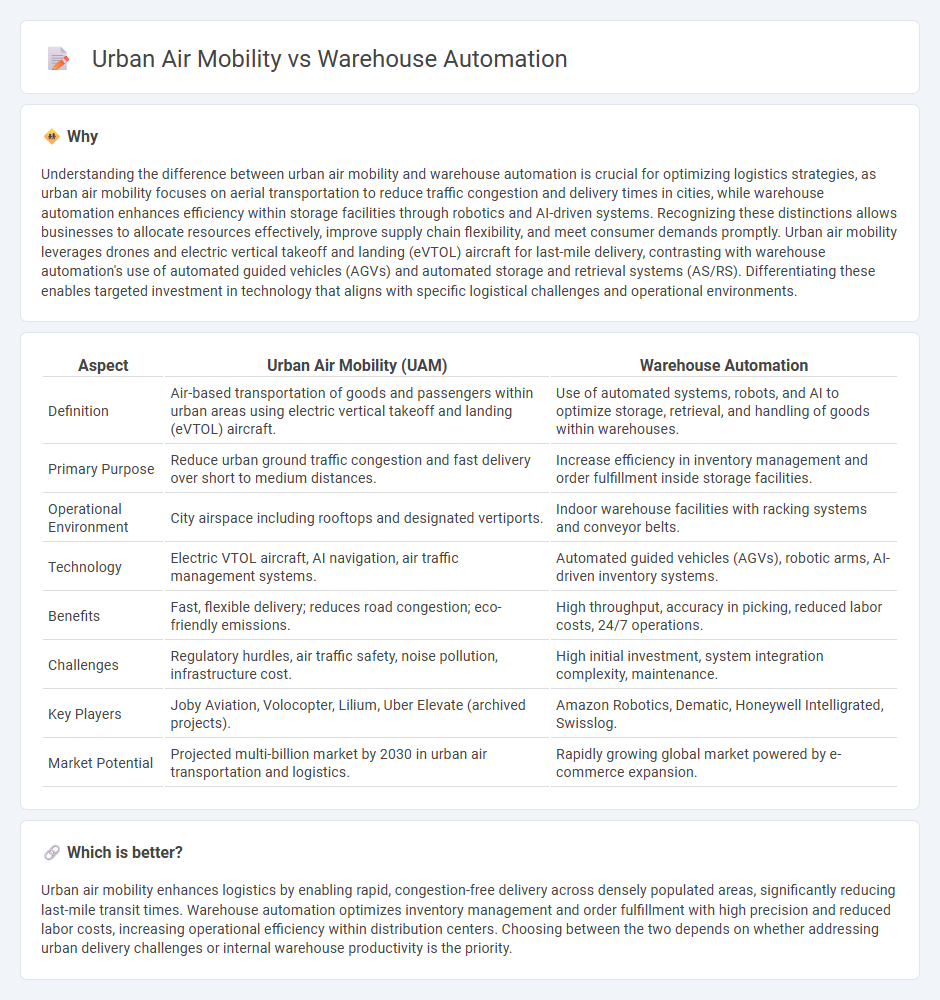

Understanding the difference between urban air mobility and warehouse automation is crucial for optimizing logistics strategies, as urban air mobility focuses on aerial transportation to reduce traffic congestion and delivery times in cities, while warehouse automation enhances efficiency within storage facilities through robotics and AI-driven systems. Recognizing these distinctions allows businesses to allocate resources effectively, improve supply chain flexibility, and meet consumer demands promptly. Urban air mobility leverages drones and electric vertical takeoff and landing (eVTOL) aircraft for last-mile delivery, contrasting with warehouse automation's use of automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS). Differentiating these enables targeted investment in technology that aligns with specific logistical challenges and operational environments.

Comparison Table

| Aspect | Urban Air Mobility (UAM) | Warehouse Automation |

|---|---|---|

| Definition | Air-based transportation of goods and passengers within urban areas using electric vertical takeoff and landing (eVTOL) aircraft. | Use of automated systems, robots, and AI to optimize storage, retrieval, and handling of goods within warehouses. |

| Primary Purpose | Reduce urban ground traffic congestion and fast delivery over short to medium distances. | Increase efficiency in inventory management and order fulfillment inside storage facilities. |

| Operational Environment | City airspace including rooftops and designated vertiports. | Indoor warehouse facilities with racking systems and conveyor belts. |

| Technology | Electric VTOL aircraft, AI navigation, air traffic management systems. | Automated guided vehicles (AGVs), robotic arms, AI-driven inventory systems. |

| Benefits | Fast, flexible delivery; reduces road congestion; eco-friendly emissions. | High throughput, accuracy in picking, reduced labor costs, 24/7 operations. |

| Challenges | Regulatory hurdles, air traffic safety, noise pollution, infrastructure cost. | High initial investment, system integration complexity, maintenance. |

| Key Players | Joby Aviation, Volocopter, Lilium, Uber Elevate (archived projects). | Amazon Robotics, Dematic, Honeywell Intelligrated, Swisslog. |

| Market Potential | Projected multi-billion market by 2030 in urban air transportation and logistics. | Rapidly growing global market powered by e-commerce expansion. |

Which is better?

Urban air mobility enhances logistics by enabling rapid, congestion-free delivery across densely populated areas, significantly reducing last-mile transit times. Warehouse automation optimizes inventory management and order fulfillment with high precision and reduced labor costs, increasing operational efficiency within distribution centers. Choosing between the two depends on whether addressing urban delivery challenges or internal warehouse productivity is the priority.

Connection

Urban air mobility integrates drone technology that enhances last-mile delivery efficiency by reducing transit times in congested urban environments, directly supporting warehouse automation systems optimized for swift inventory dispatch. Automated warehouses leverage real-time data and robotics to synchronize with aerial delivery networks, ensuring seamless coordination between inventory management and rapid aerial transport. The convergence of these technologies enables a synchronized logistics ecosystem, significantly improving supply chain responsiveness and reducing operational costs.

Key Terms

**Warehouse Automation:**

Warehouse automation streamlines operations by integrating robotics, AI-driven inventory management, and real-time data analytics to enhance efficiency, reduce errors, and lower operational costs. Advanced systems such as automated guided vehicles (AGVs) and robotic picking solutions significantly increase throughput in fulfillment centers. Explore the latest innovations in warehouse automation to boost your supply chain performance.

Robotics

Warehouse automation leverages robotics to enhance efficiency in inventory management, order fulfillment, and material handling through technologies such as autonomous mobile robots (AMRs) and robotic arm systems. Urban air mobility (UAM) integrates robotics in the form of autonomous drones and flying taxis, aiming to revolutionize urban transportation by reducing traffic congestion and shortening travel times. Explore more to understand how robotics is transforming both warehouse operations and urban air travel.

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) revolutionize warehouse automation by enhancing inventory management, reducing labor costs, and improving order accuracy through robotics and real-time data analytics. In contrast, Urban Air Mobility (UAM) focuses on transforming urban transportation with electric vertical takeoff and landing vehicles that promise faster commutes and reduced traffic congestion. Explore detailed comparisons of AS/RS innovations and UAM developments to understand their distinct impacts on logistics and urban infrastructure.

Source and External Links

Warehouse Automation Explained: Trends, Types & Best Practices - Warehouse automation automates inventory movement in and out of warehouses with minimal human help, involving steps like forming implementation committees, collecting data, evaluating inventory controls, deploying WMS platforms, and choosing the automation type aligning with goals.

13 Warehouse Automation Trends in 2025 - Conger Industries - Implementing warehouse automation requires strategic planning including feasibility studies, goal setting, budgeting, stakeholder involvement, selection of hardware like AMRs and ASRS, and seamless integration with existing systems such as WMS and ERP.

Warehouse Automation | SSI SCHAEFER - Warehouse automation involves using technologies like robotics, conveyor belts, and automated guided vehicles to optimize tasks such as storage, picking, packing, and shipping, aiming to reduce manual labor, increase accuracy, and enhance productivity with solutions like Automated Storage and Retrieval Systems (AS/RS).

dowidth.com

dowidth.com