Cross docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing supply chain efficiency. Milk run optimizes delivery routes by consolidating shipments from multiple suppliers into a single trip, reducing transportation costs and environmental impact. Explore how these logistics strategies can transform your operations and boost overall productivity.

Why it is important

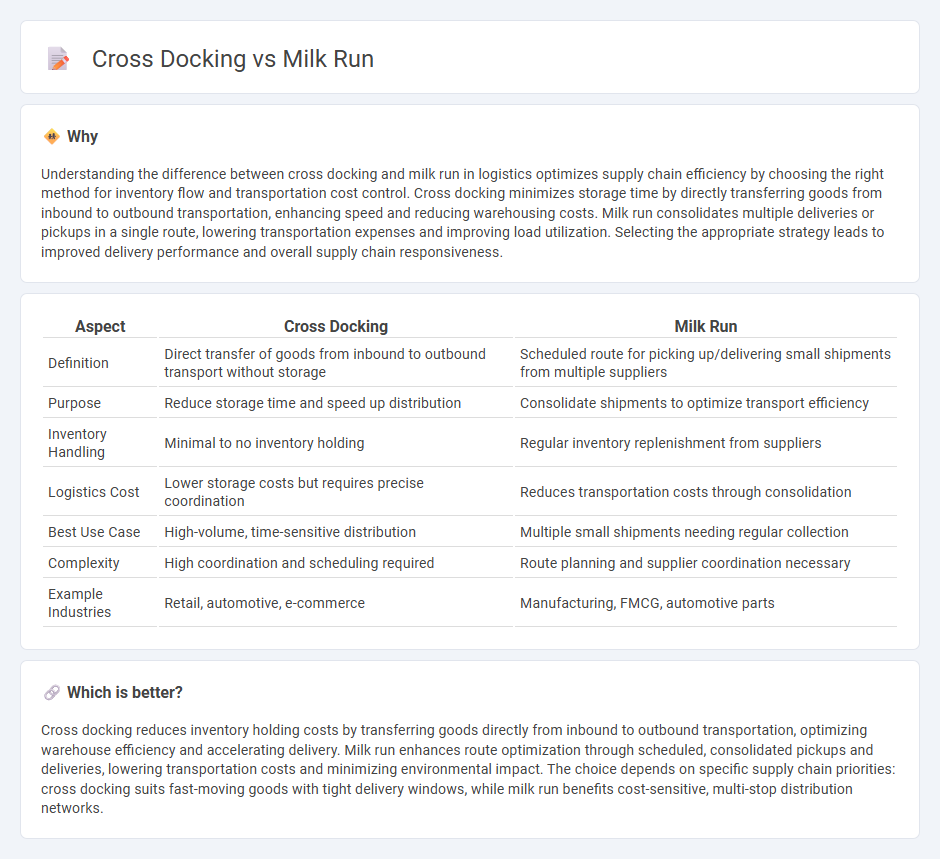

Understanding the difference between cross docking and milk run in logistics optimizes supply chain efficiency by choosing the right method for inventory flow and transportation cost control. Cross docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing speed and reducing warehousing costs. Milk run consolidates multiple deliveries or pickups in a single route, lowering transportation expenses and improving load utilization. Selecting the appropriate strategy leads to improved delivery performance and overall supply chain responsiveness.

Comparison Table

| Aspect | Cross Docking | Milk Run |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound transport without storage | Scheduled route for picking up/delivering small shipments from multiple suppliers |

| Purpose | Reduce storage time and speed up distribution | Consolidate shipments to optimize transport efficiency |

| Inventory Handling | Minimal to no inventory holding | Regular inventory replenishment from suppliers |

| Logistics Cost | Lower storage costs but requires precise coordination | Reduces transportation costs through consolidation |

| Best Use Case | High-volume, time-sensitive distribution | Multiple small shipments needing regular collection |

| Complexity | High coordination and scheduling required | Route planning and supplier coordination necessary |

| Example Industries | Retail, automotive, e-commerce | Manufacturing, FMCG, automotive parts |

Which is better?

Cross docking reduces inventory holding costs by transferring goods directly from inbound to outbound transportation, optimizing warehouse efficiency and accelerating delivery. Milk run enhances route optimization through scheduled, consolidated pickups and deliveries, lowering transportation costs and minimizing environmental impact. The choice depends on specific supply chain priorities: cross docking suits fast-moving goods with tight delivery windows, while milk run benefits cost-sensitive, multi-stop distribution networks.

Connection

Cross docking and milk run strategies enhance supply chain efficiency by minimizing storage time and optimizing transportation routes. Cross docking facilitates direct transfer of goods from inbound to outbound shipments, while milk runs consolidate deliveries from multiple suppliers into a single route to reduce transportation costs. Together, these methods streamline inventory flow, improve delivery speed, and lower operational expenses in logistics management.

Key Terms

Route Optimization

Milk run route optimization minimizes transportation costs by consolidating multiple deliveries into a single trip, improving efficiency through predictable, recurring routes. Cross docking route optimization emphasizes rapid transfer and sorting of goods at centralized hubs, reducing storage time and accelerating delivery schedules. Explore further to understand how these logistics strategies enhance supply chain performance.

Consolidation

Milk run consolidates shipments by collecting goods from multiple suppliers into a single, efficient delivery route, minimizing transportation costs and reducing carbon footprint. Cross docking focuses on immediate consolidation and redistribution of inbound goods directly to outbound shipments, eliminating storage time and speeding up delivery. Explore how these consolidation strategies optimize supply chain efficiency and meet diverse logistical needs.

Transshipment

Milk run focuses on consolidating shipments from multiple suppliers into a single transportation trip, reducing costs and improving efficiency by minimizing empty miles during transshipment. Cross docking emphasizes the rapid transfer of goods directly from inbound to outbound transportation without long-term storage, streamlining the transshipment process to accelerate delivery times. Discover more about how these logistics strategies optimize transshipment for supply chain success.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - ShipBob - Milk run is a logistics approach where one vehicle collects goods from multiple suppliers and delivers them in a single shipment to one destination, originating from the dairy industry practice of collecting milk from various farms to a processing plant.

What is a milk run in logistics? | Red Stag Fulfillment - In logistics, a milk run is a recurring, predefined route used for picking up and dropping off items at multiple stops, helping reduce costs by eliminating partial truckloads and minimizing inventory overstocking.

What is Milk Run in Logistics? - FlexQube - Milk run in lean manufacturing delivers materials more frequently to various assembly areas within a facility, optimizing production flow and reducing downtime by preventing overstock and ensuring timely restocking.

dowidth.com

dowidth.com