White glove delivery specializes in high-value, fragile, or complex shipments, offering services such as inside delivery, assembly, and installation to ensure a premium customer experience. Reverse logistics focuses on the efficient handling of returns, recycling, and disposal of products, optimizing supply chain sustainability and cost-effectiveness. Discover how these logistics strategies can enhance your business operations and customer satisfaction.

Why it is important

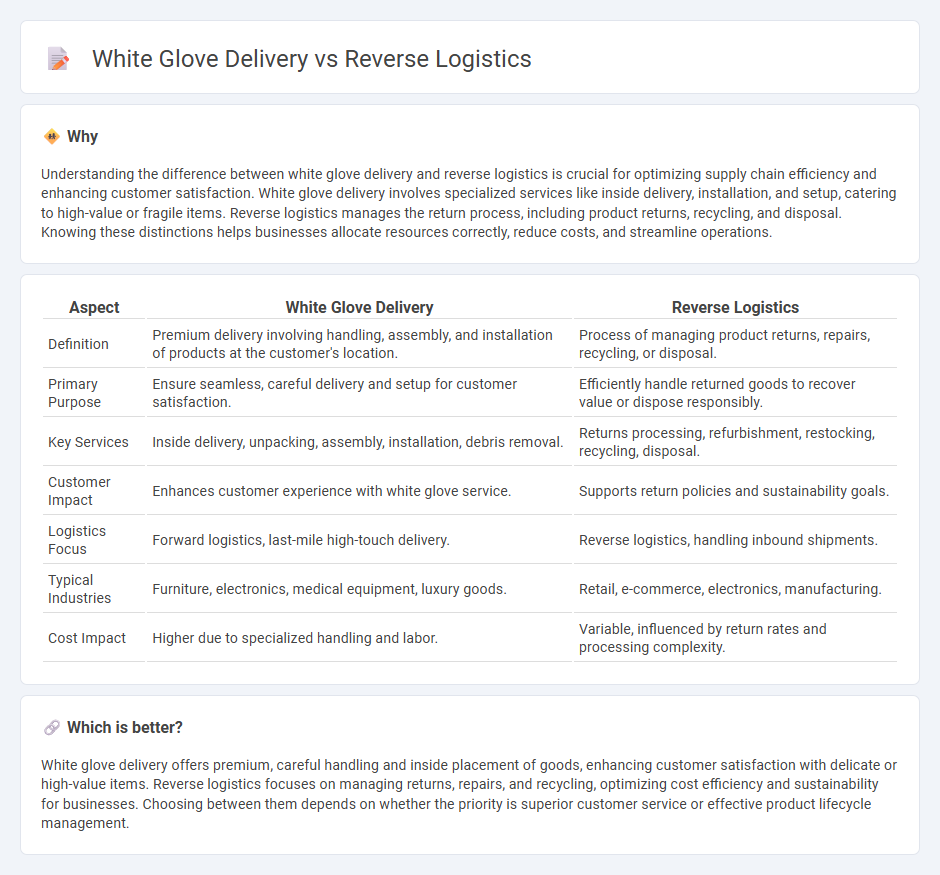

Understanding the difference between white glove delivery and reverse logistics is crucial for optimizing supply chain efficiency and enhancing customer satisfaction. White glove delivery involves specialized services like inside delivery, installation, and setup, catering to high-value or fragile items. Reverse logistics manages the return process, including product returns, recycling, and disposal. Knowing these distinctions helps businesses allocate resources correctly, reduce costs, and streamline operations.

Comparison Table

| Aspect | White Glove Delivery | Reverse Logistics |

|---|---|---|

| Definition | Premium delivery involving handling, assembly, and installation of products at the customer's location. | Process of managing product returns, repairs, recycling, or disposal. |

| Primary Purpose | Ensure seamless, careful delivery and setup for customer satisfaction. | Efficiently handle returned goods to recover value or dispose responsibly. |

| Key Services | Inside delivery, unpacking, assembly, installation, debris removal. | Returns processing, refurbishment, restocking, recycling, disposal. |

| Customer Impact | Enhances customer experience with white glove service. | Supports return policies and sustainability goals. |

| Logistics Focus | Forward logistics, last-mile high-touch delivery. | Reverse logistics, handling inbound shipments. |

| Typical Industries | Furniture, electronics, medical equipment, luxury goods. | Retail, e-commerce, electronics, manufacturing. |

| Cost Impact | Higher due to specialized handling and labor. | Variable, influenced by return rates and processing complexity. |

Which is better?

White glove delivery offers premium, careful handling and inside placement of goods, enhancing customer satisfaction with delicate or high-value items. Reverse logistics focuses on managing returns, repairs, and recycling, optimizing cost efficiency and sustainability for businesses. Choosing between them depends on whether the priority is superior customer service or effective product lifecycle management.

Connection

White glove delivery and reverse logistics intersect through their focus on enhanced customer experience and efficient handling of goods during both final delivery and product returns. White glove delivery provides specialized services such as careful product installation, assembly, and debris removal, which seamlessly integrate with reverse logistics processes that manage return shipments, refurbishment, and restocking. This connectivity ensures reduced damage, improved service quality, and optimized supply chain efficiency throughout product lifecycle management.

Key Terms

Reverse Logistics:

Reverse logistics involves the process of returning goods from customers to the manufacturer or warehouse for repair, recycling, or disposal, enhancing sustainability and reducing waste. It includes activities like product returns management, remanufacturing, and refurbishing, which optimize supply chain efficiency and customer satisfaction. Discover more about how reverse logistics can streamline your operations and boost profitability.

Returns Management

Reverse logistics centers on efficiently managing product returns, including inspection, refurbishing, and restocking to optimize supply chain sustainability and reduce costs. White glove delivery emphasizes premium, in-home services such as setup, assembly, and careful handling during the return process to enhance customer experience. Explore detailed strategies to improve your returns management and discover how combining these approaches benefits your business.

Asset Recovery

Reverse logistics involves the process of returning products from customers to manufacturers for refurbishment, recycling, or disposal, playing a critical role in asset recovery by minimizing waste and recovering value from used goods. White glove delivery enhances customer experience through premium handling services like in-home delivery, installation, and packaging removal but focuses less on the asset recovery aspect and more on service quality. Explore how integrating reverse logistics with white glove services can optimize asset recovery strategies and improve overall lifecycle management.

Source and External Links

What is Reverse Logistics? - c3controls - Reverse logistics is the process of moving goods from the customer back to the manufacturer or distributor for return, repair, remanufacture, recycling, or disposal, aimed at cost-effective management while supporting sustainability and efficiency in the supply chain.

A Guide to Reverse Logistics: How It Works, Types and Strategies - Reverse logistics manages returns, surplus goods, and refurbishments by moving products back from customers to sellers or manufacturers, adapting across industries to reduce waste and recapture value.

Reverse logistics - Wikipedia - Reverse logistics involves moving goods from their final destination upstream in the supply chain for value recovery or proper disposal, including remanufacturing and refurbishing, and has grown in importance with green supply chain practices.

dowidth.com

dowidth.com