Containerization revolutionizes logistics by enabling standardized, secure transport of goods across global supply chains, reducing handling times and minimizing damage. Milk run logistics optimizes delivery routes by consolidating multiple shipments into a single trip, enhancing efficiency and lowering transportation costs. Explore how containerization compares to milk run strategies to optimize your supply chain performance.

Why it is important

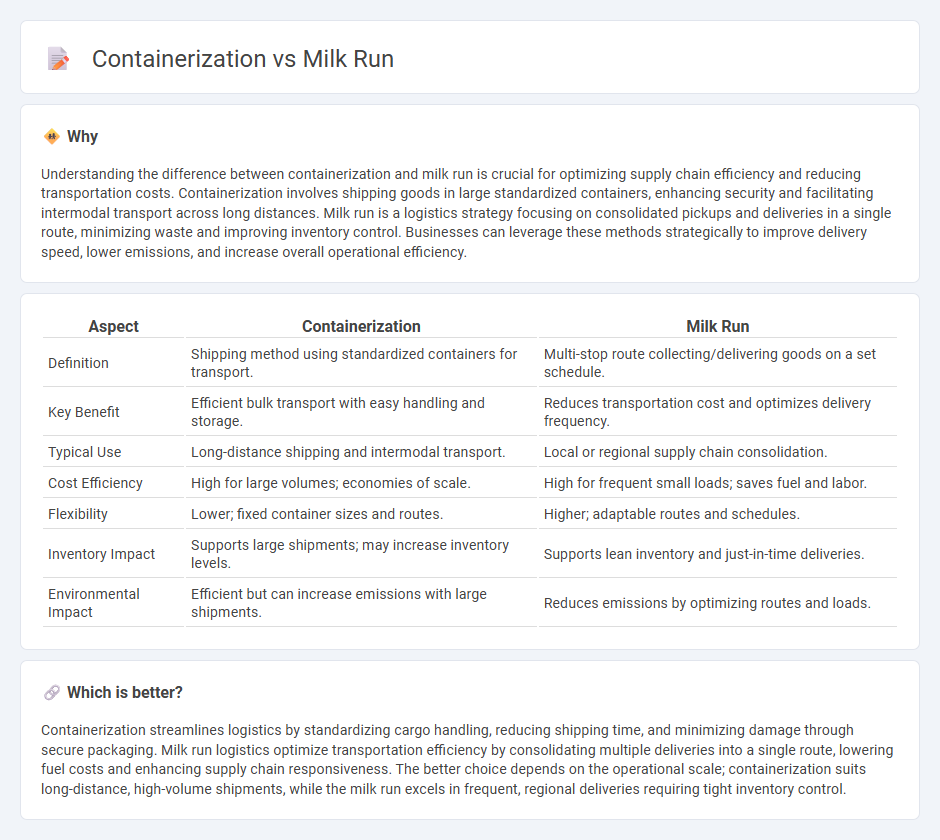

Understanding the difference between containerization and milk run is crucial for optimizing supply chain efficiency and reducing transportation costs. Containerization involves shipping goods in large standardized containers, enhancing security and facilitating intermodal transport across long distances. Milk run is a logistics strategy focusing on consolidated pickups and deliveries in a single route, minimizing waste and improving inventory control. Businesses can leverage these methods strategically to improve delivery speed, lower emissions, and increase overall operational efficiency.

Comparison Table

| Aspect | Containerization | Milk Run |

|---|---|---|

| Definition | Shipping method using standardized containers for transport. | Multi-stop route collecting/delivering goods on a set schedule. |

| Key Benefit | Efficient bulk transport with easy handling and storage. | Reduces transportation cost and optimizes delivery frequency. |

| Typical Use | Long-distance shipping and intermodal transport. | Local or regional supply chain consolidation. |

| Cost Efficiency | High for large volumes; economies of scale. | High for frequent small loads; saves fuel and labor. |

| Flexibility | Lower; fixed container sizes and routes. | Higher; adaptable routes and schedules. |

| Inventory Impact | Supports large shipments; may increase inventory levels. | Supports lean inventory and just-in-time deliveries. |

| Environmental Impact | Efficient but can increase emissions with large shipments. | Reduces emissions by optimizing routes and loads. |

Which is better?

Containerization streamlines logistics by standardizing cargo handling, reducing shipping time, and minimizing damage through secure packaging. Milk run logistics optimize transportation efficiency by consolidating multiple deliveries into a single route, lowering fuel costs and enhancing supply chain responsiveness. The better choice depends on the operational scale; containerization suits long-distance, high-volume shipments, while the milk run excels in frequent, regional deliveries requiring tight inventory control.

Connection

Containerization enhances the efficiency of milk run logistics by standardizing cargo units, enabling seamless loading, unloading, and transfer across multiple stops. Milk run operations optimize supply chain routes for frequent, consolidated deliveries, reducing transportation costs and lead times. The integration of containerization within milk runs streamlines material flow, improves inventory management, and supports just-in-time (JIT) delivery systems.

Key Terms

Route Optimization

Milk run logistics maximizes route efficiency by consolidating multiple deliveries into a single trip, reducing transportation costs and minimizing empty miles. Containerization streamlines cargo handling and secures goods but may involve less flexible routing due to fixed container schedules and volumes. Explore how combining milk run strategies with containerization can unlock superior route optimization benefits.

Load Consolidation

Milk run optimizes load consolidation by combining multiple small shipments from various suppliers into a single delivery route, reducing transportation costs and increasing efficiency. Containerization focuses on maximizing container space utilization by consolidating goods into standardized containers, facilitating easier handling and minimizing cargo damage. Explore more to understand the operational advantages and strategic applications of each method.

Packaging Standardization

Milk run logistics minimizes packaging waste by utilizing standardized containers for frequent, consolidated shipments, improving load efficiency and reducing handling. Containerization emphasizes global shipping efficiency through uniform packaging standards, facilitating intermodal transport and reducing damage risks during transit. Explore detailed comparisons to understand how packaging standardization impacts supply chain optimization.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - Explains the concept of milk run logistics, its origins, and its application in modern supply chain management.

What is a milk run in logistics? - Defines milk run in logistics and its benefits, such as eliminating partial truckloads and optimizing real-time inventory use.

What Is a Milk Run? - Describes the milk run as a delivery method transporting mixed loads from multiple suppliers to one customer, highlighting its use in supply chains.

dowidth.com

dowidth.com