Milk run logistics optimize supply chain efficiency by consolidating multiple deliveries into a single route, reducing transportation costs and minimizing inventory levels. Drop-shipping eliminates the need for warehousing by directly shipping products from suppliers to customers, accelerating order fulfillment and lowering overhead expenses. Discover the best strategy to streamline your supply chain and boost operational agility.

Why it is important

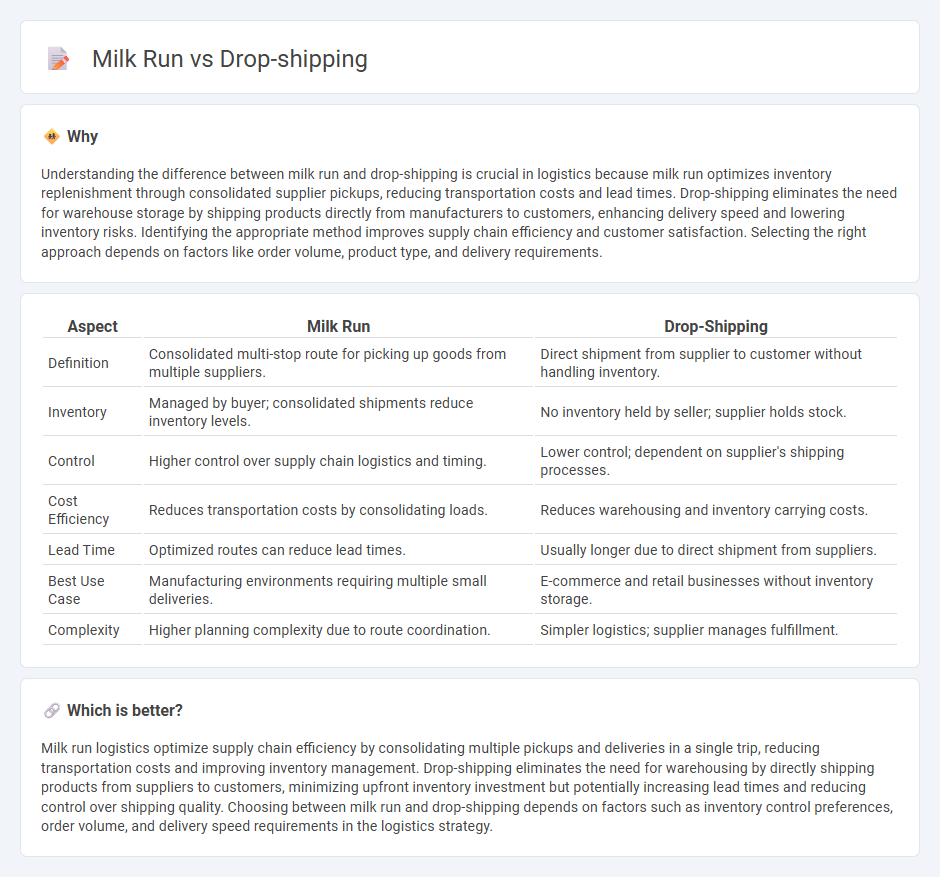

Understanding the difference between milk run and drop-shipping is crucial in logistics because milk run optimizes inventory replenishment through consolidated supplier pickups, reducing transportation costs and lead times. Drop-shipping eliminates the need for warehouse storage by shipping products directly from manufacturers to customers, enhancing delivery speed and lowering inventory risks. Identifying the appropriate method improves supply chain efficiency and customer satisfaction. Selecting the right approach depends on factors like order volume, product type, and delivery requirements.

Comparison Table

| Aspect | Milk Run | Drop-Shipping |

|---|---|---|

| Definition | Consolidated multi-stop route for picking up goods from multiple suppliers. | Direct shipment from supplier to customer without handling inventory. |

| Inventory | Managed by buyer; consolidated shipments reduce inventory levels. | No inventory held by seller; supplier holds stock. |

| Control | Higher control over supply chain logistics and timing. | Lower control; dependent on supplier's shipping processes. |

| Cost Efficiency | Reduces transportation costs by consolidating loads. | Reduces warehousing and inventory carrying costs. |

| Lead Time | Optimized routes can reduce lead times. | Usually longer due to direct shipment from suppliers. |

| Best Use Case | Manufacturing environments requiring multiple small deliveries. | E-commerce and retail businesses without inventory storage. |

| Complexity | Higher planning complexity due to route coordination. | Simpler logistics; supplier manages fulfillment. |

Which is better?

Milk run logistics optimize supply chain efficiency by consolidating multiple pickups and deliveries in a single trip, reducing transportation costs and improving inventory management. Drop-shipping eliminates the need for warehousing by directly shipping products from suppliers to customers, minimizing upfront inventory investment but potentially increasing lead times and reducing control over shipping quality. Choosing between milk run and drop-shipping depends on factors such as inventory control preferences, order volume, and delivery speed requirements in the logistics strategy.

Connection

Milk run and drop-shipping both optimize supply chain efficiency by minimizing inventory costs and reducing transportation waste. Milk run consolidates shipments by collecting goods from multiple suppliers in a single trip, while drop-shipping involves direct delivery from supplier to end customer without holding inventory. Integrating these methods enhances just-in-time delivery and lowers overall logistics expenses.

Key Terms

Inventory Ownership

Drop-shipping minimizes inventory ownership by allowing retailers to fulfill orders directly from suppliers, reducing storage costs and financial risk. Milk run logistics consolidates shipments by picking up inventory from multiple suppliers, maintaining ownership while optimizing transportation efficiency and inventory control. Discover how choosing between drop-shipping and milk run impacts your supply chain strategy and inventory management.

Routing Efficiency

Drop-shipping eliminates intermediary storage by shipping products directly from suppliers to customers, streamlining supply chain steps and reducing overall transit time. Milk run routes optimize delivery by combining multiple shipments into a single trip, minimizing transportation costs and improving load utilization. Explore the benefits of each method to enhance your logistics and routing efficiency strategies.

Order Fulfillment

Drop-shipping streamlines order fulfillment by directly shipping products from suppliers to customers, reducing inventory holding costs and enabling faster delivery times. Milk run logistics optimize order fulfillment through scheduled multi-stop routes, consolidating shipments to lower transportation expenses and improve supply chain efficiency. Explore comprehensive strategies to determine the best order fulfillment model for your business needs.

Source and External Links

Drop shipping - Wikipedia - Drop shipping is a retail business model where the seller accepts orders but does not keep stock; instead, the order and shipment details are sent to a supplier who ships directly to the customer, minimizing overhead costs but reducing control over product quality and delivery.

What Is Dropshipping and How Does It Work? (2025) - Shopify - Dropshipping involves partnering with suppliers who store and ship products directly to customers from your online store, where you handle marketing and sales while order forwarding to suppliers is often automated via apps.

Drop-Shipping: What you Need to Know Before You Buy or Sell Online - Drop-shipping occurs when a seller offers products without stocking them, forwarding customer orders to a wholesaler or manufacturer who ships directly to buyers; although legal, it can present risks in the buyer-seller relationship.

dowidth.com

dowidth.com