Cold chain traceability ensures the complete documentation of temperature-controlled products throughout the supply chain by recording every handling and storage event. Temperature monitoring focuses on real-time sensor data to detect and alert deviations from preset temperature ranges, preventing spoilage and ensuring compliance with safety standards. Explore how integrating both systems optimizes product integrity and regulatory adherence in logistics.

Why it is important

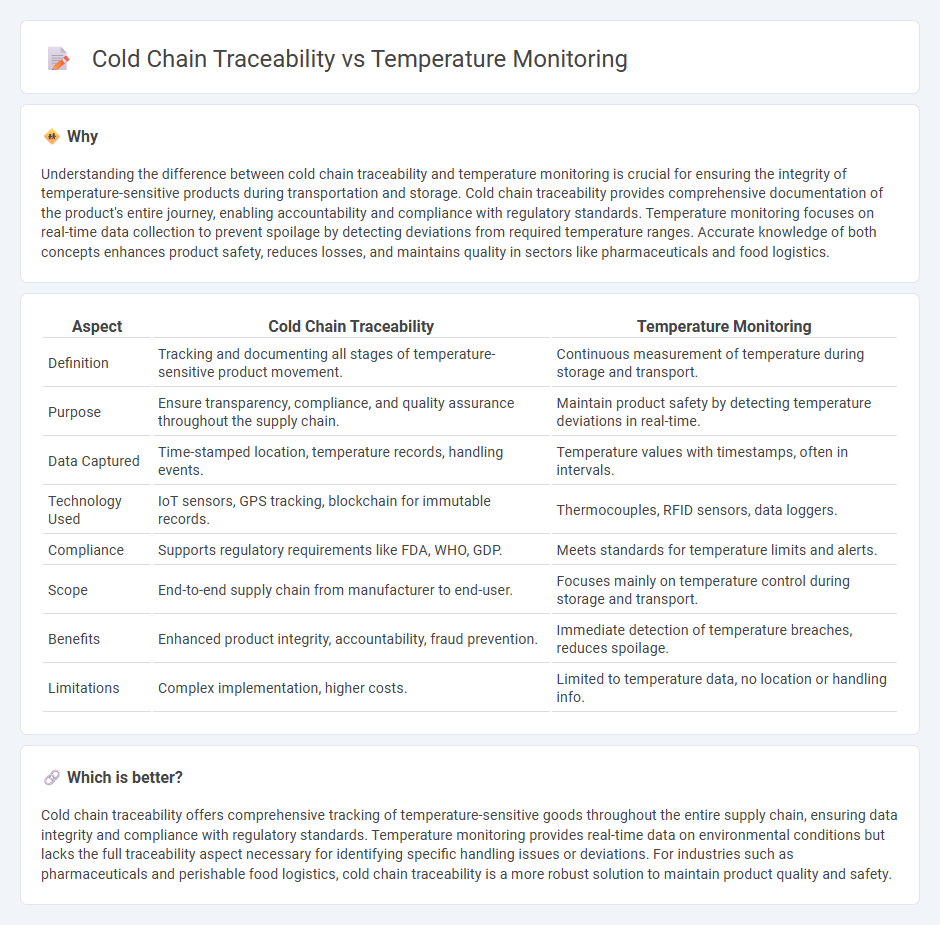

Understanding the difference between cold chain traceability and temperature monitoring is crucial for ensuring the integrity of temperature-sensitive products during transportation and storage. Cold chain traceability provides comprehensive documentation of the product's entire journey, enabling accountability and compliance with regulatory standards. Temperature monitoring focuses on real-time data collection to prevent spoilage by detecting deviations from required temperature ranges. Accurate knowledge of both concepts enhances product safety, reduces losses, and maintains quality in sectors like pharmaceuticals and food logistics.

Comparison Table

| Aspect | Cold Chain Traceability | Temperature Monitoring |

|---|---|---|

| Definition | Tracking and documenting all stages of temperature-sensitive product movement. | Continuous measurement of temperature during storage and transport. |

| Purpose | Ensure transparency, compliance, and quality assurance throughout the supply chain. | Maintain product safety by detecting temperature deviations in real-time. |

| Data Captured | Time-stamped location, temperature records, handling events. | Temperature values with timestamps, often in intervals. |

| Technology Used | IoT sensors, GPS tracking, blockchain for immutable records. | Thermocouples, RFID sensors, data loggers. |

| Compliance | Supports regulatory requirements like FDA, WHO, GDP. | Meets standards for temperature limits and alerts. |

| Scope | End-to-end supply chain from manufacturer to end-user. | Focuses mainly on temperature control during storage and transport. |

| Benefits | Enhanced product integrity, accountability, fraud prevention. | Immediate detection of temperature breaches, reduces spoilage. |

| Limitations | Complex implementation, higher costs. | Limited to temperature data, no location or handling info. |

Which is better?

Cold chain traceability offers comprehensive tracking of temperature-sensitive goods throughout the entire supply chain, ensuring data integrity and compliance with regulatory standards. Temperature monitoring provides real-time data on environmental conditions but lacks the full traceability aspect necessary for identifying specific handling issues or deviations. For industries such as pharmaceuticals and perishable food logistics, cold chain traceability is a more robust solution to maintain product quality and safety.

Connection

Cold chain traceability relies on precise temperature monitoring to ensure the integrity of perishable goods throughout transportation and storage. Real-time temperature data allows for immediate detection of deviations, minimizing spoilage risks and maintaining compliance with safety regulations. This integrated system enhances supply chain transparency and supports quality assurance from origin to destination.

Key Terms

Temperature monitoring:

Temperature monitoring involves continuous tracking of temperature data within transportation or storage environments to ensure optimal conditions for perishable goods, pharmaceuticals, and sensitive materials. It employs advanced sensors and IoT technology to provide real-time alerts and detailed logs, minimizing spoilage and regulatory risks. Explore comprehensive solutions to enhance your temperature monitoring systems and safeguard your cold chain integrity.

Data loggers

Data loggers are essential for temperature monitoring by continuously recording temperature readings to ensure product safety, especially in pharmaceuticals and food industries. Cold chain traceability involves tracking the temperature data alongside shipment and storage conditions throughout the supply chain to guarantee compliance with regulatory standards. Explore how integrating advanced data loggers enhances cold chain traceability and optimizes supply chain management.

Real-time sensors

Real-time sensors provide continuous temperature monitoring critical for maintaining cold chain integrity in pharmaceuticals and perishable goods, ensuring product safety and compliance with regulatory standards. These sensors enable immediate detection of temperature deviations, reducing spoilage risks and improving supply chain transparency compared to traditional monitoring methods. Explore advancements in real-time sensor technology to enhance your cold chain traceability and optimize product quality assurance.

Source and External Links

ThermoWorks NODE(r) | Professional Wi-Fi Temperature Monitoring - ThermoWorks NODE allows 24/7 remote temperature and humidity monitoring with instant alerts on your phone and a secure cloud dashboard for multi-channel graphing and history tracking.

Temp Stick(r) by Ideal Sciences -- Official Website - Temp Stick is a wireless WiFi temperature and humidity sensor offering real-time alerts, no subscription fees, and long battery life, designed for versatile uses like coolers, server rooms, and greenhouses.

Temperature measurement - Wikipedia - Temperature measurement involves devices such as thermometers, thermocouples, thermistors, and infrared thermometers that detect temperature by measuring physical properties that vary with temperature, ensuring accuracy despite possible heat transfer effects.

dowidth.com

dowidth.com