Milk run logistics optimizes supply chains by using scheduled routes to pick up multiple small shipments from various suppliers, reducing transportation costs and improving delivery efficiency. Consolidation centers gather goods from different sources to combine shipments into larger loads, streamlining inventory management and decreasing overall freight expenses. Explore how these strategies can transform your logistics operations by enhancing distribution efficiency and cost savings.

Why it is important

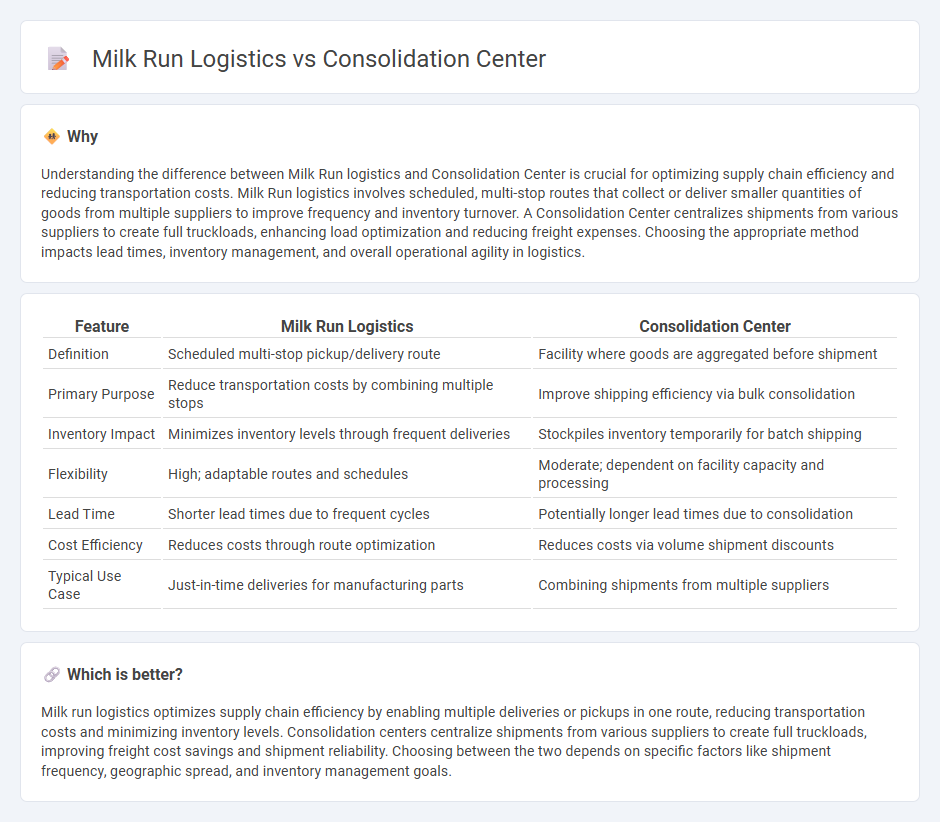

Understanding the difference between Milk Run logistics and Consolidation Center is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk Run logistics involves scheduled, multi-stop routes that collect or deliver smaller quantities of goods from multiple suppliers to improve frequency and inventory turnover. A Consolidation Center centralizes shipments from various suppliers to create full truckloads, enhancing load optimization and reducing freight expenses. Choosing the appropriate method impacts lead times, inventory management, and overall operational agility in logistics.

Comparison Table

| Feature | Milk Run Logistics | Consolidation Center |

|---|---|---|

| Definition | Scheduled multi-stop pickup/delivery route | Facility where goods are aggregated before shipment |

| Primary Purpose | Reduce transportation costs by combining multiple stops | Improve shipping efficiency via bulk consolidation |

| Inventory Impact | Minimizes inventory levels through frequent deliveries | Stockpiles inventory temporarily for batch shipping |

| Flexibility | High; adaptable routes and schedules | Moderate; dependent on facility capacity and processing |

| Lead Time | Shorter lead times due to frequent cycles | Potentially longer lead times due to consolidation |

| Cost Efficiency | Reduces costs through route optimization | Reduces costs via volume shipment discounts |

| Typical Use Case | Just-in-time deliveries for manufacturing parts | Combining shipments from multiple suppliers |

Which is better?

Milk run logistics optimizes supply chain efficiency by enabling multiple deliveries or pickups in one route, reducing transportation costs and minimizing inventory levels. Consolidation centers centralize shipments from various suppliers to create full truckloads, improving freight cost savings and shipment reliability. Choosing between the two depends on specific factors like shipment frequency, geographic spread, and inventory management goals.

Connection

Milk run logistics optimizes supply chain efficiency by coordinating multiple pickups and deliveries in a single, recurring route, minimizing transportation costs and reducing lead times. A Consolidation Center serves as a pivotal hub where goods from various suppliers are aggregated before shipment, enhancing load optimization and inventory management. Together, milk run logistics and Consolidation Centers streamline distribution by improving shipment frequency, reducing transportation expenses, and ensuring timely delivery in supply chain operations.

Key Terms

Cross-docking

Consolidation centers aggregate shipments from multiple suppliers to optimize load capacity before dispatch, reducing transportation costs and improving shipment efficiency. Milk run logistics involve a single vehicle collecting small loads from several suppliers in a scheduled routing, minimizing vehicle miles traveled and enhancing delivery frequency. Exploring how cross-docking integrates with these methods reveals opportunities to streamline supply chains and reduce inventory holding times, offering significant operational benefits--discover more insights here.

Route optimization

Route optimization in consolidation centers leverages centralized hub operations to group shipments, reducing transportation costs and improving delivery efficiency. Milk run logistics employs scheduled, multi-stop routes designed to pick up or deliver goods along a fixed loop, minimizing empty miles and enhancing vehicle utilization. Explore more to understand which method best suits your supply chain needs.

Load pooling

Load pooling enhances efficiency in logistics by combining shipments from multiple sources into consolidated loads, reducing transportation costs and minimizing empty miles. Consolidation centers serve as strategic hubs where goods are merged and redistributed, optimizing route planning and inventory management. Explore how leveraging load pooling in consolidation centers compares to milk run logistics for streamlined supply chain operations.

Source and External Links

Consolidation Center Definition and Meaning - Buske Logistics - A consolidation center is a logistics facility that gathers multiple small shipments from different suppliers, combines them into larger loads, and ships them together to reduce transportation costs and improve delivery efficiency by acting as a central hub to streamline supply chains.

How Walmart's Consolidation Centre Improves the Supply Chain - Walmart's high-tech consolidation centre consolidates smaller freight loads from suppliers into full truckloads, improving supply chain efficiency, reducing lead times, and enabling cost savings that benefit customers and suppliers alike.

Warehouse consolidation: what's its role in logistics? - Mecalux - A consolidation warehouse receives individual orders from multiple sources and groups them into larger shipments, organizing and sorting orders to facilitate transportation and optimize load consolidation in logistics operations.

dowidth.com

dowidth.com