Cold chain logistics involves the temperature-controlled supply chain processes essential for preserving perishable goods such as pharmaceuticals, food, and chemicals during storage and transportation. Just-in-time (JIT) logistics focuses on minimizing inventory by synchronizing supply delivery precisely with production schedules, enhancing efficiency and reducing storage costs. Explore further to understand which logistics strategy aligns best with your business needs and operational goals.

Why it is important

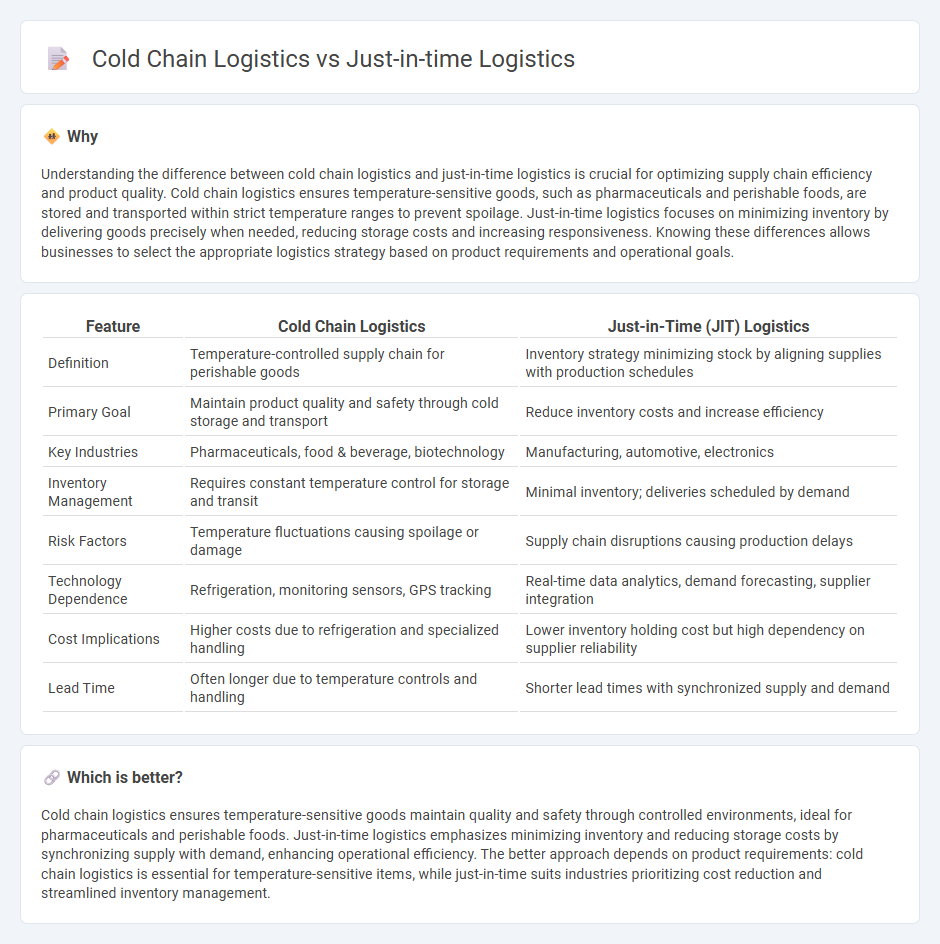

Understanding the difference between cold chain logistics and just-in-time logistics is crucial for optimizing supply chain efficiency and product quality. Cold chain logistics ensures temperature-sensitive goods, such as pharmaceuticals and perishable foods, are stored and transported within strict temperature ranges to prevent spoilage. Just-in-time logistics focuses on minimizing inventory by delivering goods precisely when needed, reducing storage costs and increasing responsiveness. Knowing these differences allows businesses to select the appropriate logistics strategy based on product requirements and operational goals.

Comparison Table

| Feature | Cold Chain Logistics | Just-in-Time (JIT) Logistics |

|---|---|---|

| Definition | Temperature-controlled supply chain for perishable goods | Inventory strategy minimizing stock by aligning supplies with production schedules |

| Primary Goal | Maintain product quality and safety through cold storage and transport | Reduce inventory costs and increase efficiency |

| Key Industries | Pharmaceuticals, food & beverage, biotechnology | Manufacturing, automotive, electronics |

| Inventory Management | Requires constant temperature control for storage and transit | Minimal inventory; deliveries scheduled by demand |

| Risk Factors | Temperature fluctuations causing spoilage or damage | Supply chain disruptions causing production delays |

| Technology Dependence | Refrigeration, monitoring sensors, GPS tracking | Real-time data analytics, demand forecasting, supplier integration |

| Cost Implications | Higher costs due to refrigeration and specialized handling | Lower inventory holding cost but high dependency on supplier reliability |

| Lead Time | Often longer due to temperature controls and handling | Shorter lead times with synchronized supply and demand |

Which is better?

Cold chain logistics ensures temperature-sensitive goods maintain quality and safety through controlled environments, ideal for pharmaceuticals and perishable foods. Just-in-time logistics emphasizes minimizing inventory and reducing storage costs by synchronizing supply with demand, enhancing operational efficiency. The better approach depends on product requirements: cold chain logistics is essential for temperature-sensitive items, while just-in-time suits industries prioritizing cost reduction and streamlined inventory management.

Connection

Cold chain logistics ensures the efficient transportation and storage of temperature-sensitive goods, maintaining product integrity from origin to destination. Just-in-time logistics minimizes inventory by synchronizing deliveries exactly when needed, reducing storage costs and waste. Integrating cold chain with just-in-time logistics optimizes supply chains for perishable products, enhancing freshness while cutting errors and delays.

Key Terms

Just-in-Time Logistics:

Just-in-Time (JIT) Logistics emphasizes minimizing inventory holding costs by synchronizing delivery schedules with production processes, ensuring materials arrive exactly when needed to reduce waste and improve efficiency. It relies heavily on precise demand forecasting, real-time tracking, and strong supplier relationships to avoid production delays and excess stock. Explore deeper insights into how JIT logistics transforms supply chain management and boosts operational agility.

Inventory Reduction

Just-in-time logistics emphasizes minimizing inventory levels by synchronizing supply with production schedules, thereby reducing holding costs and waste. Cold chain logistics focuses on preserving temperature-sensitive products through controlled environments, often requiring specialized storage and transport that can increase inventory complexity and costs. Explore how these logistics strategies balance inventory reduction with operational efficiency.

Lead Time

Just-in-time logistics emphasizes minimizing lead time by synchronizing inventory delivery precisely with production schedules to reduce storage costs and increase efficiency. Cold chain logistics, however, prioritizes maintaining temperature-controlled environments throughout transportation, which can extend lead times due to specialized handling and compliance requirements. Explore how optimizing lead time in both logistics types can enhance supply chain performance and product quality.

Source and External Links

Just-in-Time (JIT) Logistics Strategy - JIT logistics is a strategy that delivers goods exactly when needed to reduce inventory costs, improve efficiency, and require precise coordination among suppliers, manufacturers, and carriers to minimize waste and maintain smooth production flow.

Just-in-Time Logistics & Distribution: Meaning & Examples - JIT logistics synchronizes material arrivals with production schedules to minimize inventory and storage costs, relying on accurate demand forecasting and strong collaboration across the supply chain for efficient, responsive operations.

What is Just-in-Time (JIT) Logistics? Principles and Benefits - JIT logistics focuses on aligning deliveries with production needs to improve efficiency, reduce waste, and shorten production cycles, achieved through precise demand planning, supplier relationships, and optimized transport time.

dowidth.com

dowidth.com