Ghost warehousing optimizes inventory management by utilizing multiple hidden storage locations that reduce handling costs and improve order fulfillment speed. Cross-docking streamlines supply chains through direct transfer of products from inbound to outbound transport, minimizing storage time and accelerating delivery. Explore these logistics strategies to determine the best fit for your supply chain efficiency.

Why it is important

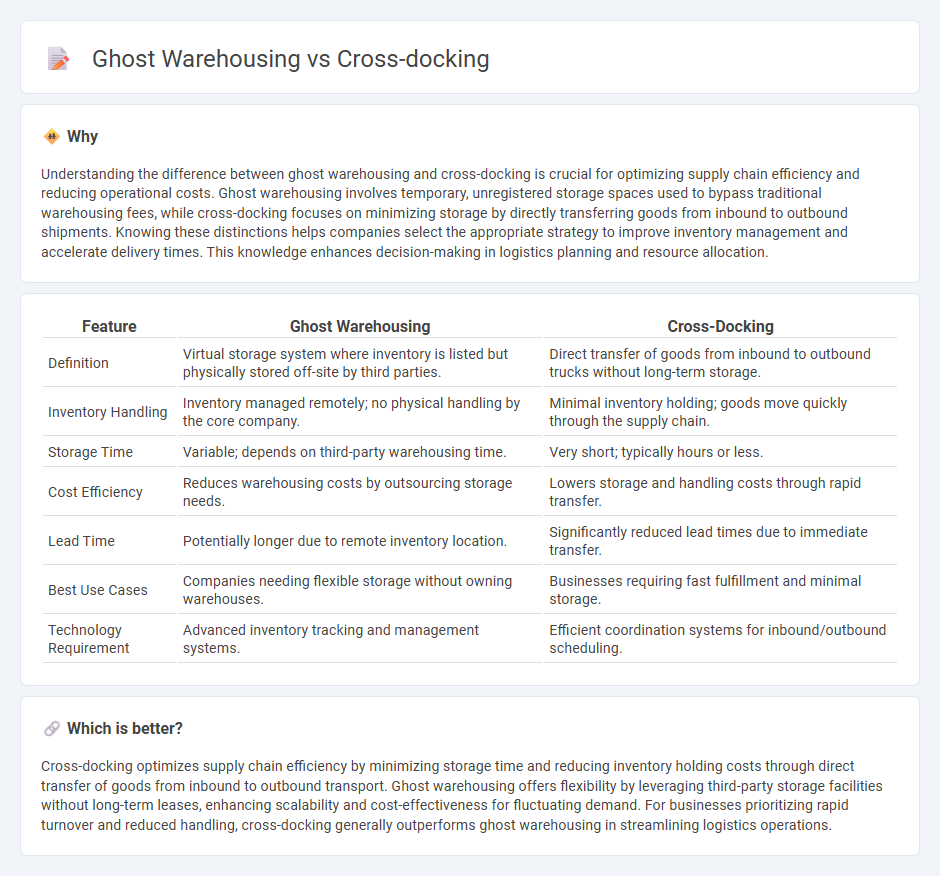

Understanding the difference between ghost warehousing and cross-docking is crucial for optimizing supply chain efficiency and reducing operational costs. Ghost warehousing involves temporary, unregistered storage spaces used to bypass traditional warehousing fees, while cross-docking focuses on minimizing storage by directly transferring goods from inbound to outbound shipments. Knowing these distinctions helps companies select the appropriate strategy to improve inventory management and accelerate delivery times. This knowledge enhances decision-making in logistics planning and resource allocation.

Comparison Table

| Feature | Ghost Warehousing | Cross-Docking |

|---|---|---|

| Definition | Virtual storage system where inventory is listed but physically stored off-site by third parties. | Direct transfer of goods from inbound to outbound trucks without long-term storage. |

| Inventory Handling | Inventory managed remotely; no physical handling by the core company. | Minimal inventory holding; goods move quickly through the supply chain. |

| Storage Time | Variable; depends on third-party warehousing time. | Very short; typically hours or less. |

| Cost Efficiency | Reduces warehousing costs by outsourcing storage needs. | Lowers storage and handling costs through rapid transfer. |

| Lead Time | Potentially longer due to remote inventory location. | Significantly reduced lead times due to immediate transfer. |

| Best Use Cases | Companies needing flexible storage without owning warehouses. | Businesses requiring fast fulfillment and minimal storage. |

| Technology Requirement | Advanced inventory tracking and management systems. | Efficient coordination systems for inbound/outbound scheduling. |

Which is better?

Cross-docking optimizes supply chain efficiency by minimizing storage time and reducing inventory holding costs through direct transfer of goods from inbound to outbound transport. Ghost warehousing offers flexibility by leveraging third-party storage facilities without long-term leases, enhancing scalability and cost-effectiveness for fluctuating demand. For businesses prioritizing rapid turnover and reduced handling, cross-docking generally outperforms ghost warehousing in streamlining logistics operations.

Connection

Ghost warehousing enhances cross-docking efficiency by providing virtual inventory visibility without physical storage, enabling real-time order processing and faster distribution. This concept reduces storage costs and streamlines supply chain operations by facilitating seamless transfer of goods from inbound to outbound transportation. The integration of ghost warehousing with cross-docking accelerates delivery times and improves inventory accuracy in logistics management.

Key Terms

Inventory Flow

Cross-docking minimizes inventory holding by directly transferring inbound shipments to outbound transportation, accelerating order fulfillment and reducing storage costs. Ghost warehousing, however, involves virtual inventory management where stock appears available but is physically stored elsewhere, optimizing warehouse space and inventory visibility without immediate physical handling. Explore detailed strategies and benefits of each approach to enhance your supply chain efficiency.

Storage Utilization

Cross-docking minimizes storage utilization by directly transferring incoming goods to outbound shipments, reducing or eliminating the need for inventory holding. Ghost warehousing, on the other hand, involves leveraging third-party warehouse capacity without physical ownership, optimizing space without permanent storage commitments. Explore detailed comparisons to fully understand how each strategy impacts storage efficiency and operational costs.

Order Fulfillment Speed

Cross-docking accelerates order fulfillment by directly transferring inbound goods to outbound transportation, eliminating storage time and reducing handling delays. Ghost warehousing, though it optimizes inventory visibility and distribution, involves some level of storage, which can slightly slow down immediate order processing compared to cross-docking. Explore how these strategies impact your supply chain efficiency for faster delivery outcomes.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from inbound to outbound transportation with minimal storage, realized through methods like continuous cross docking, consolidation, and de-consolidation to optimize flow and costs.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a logistics technique that speeds up delivery and reduces warehouse storage by directly transferring goods from inbound to outbound trucks, benefiting retailers, manufacturers, and freight carriers by increasing supply chain efficiency.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking is a logistics process for moving products directly from suppliers to customers with minimal storage, categorized by timing (pre- or post-distribution) and methods (continuous, consolidation, deconsolidation), including specialized forms for retail, manufacturing, and e-commerce.

dowidth.com

dowidth.com