Supply chain control towers provide real-time visibility and centralized management of logistics operations, enhancing decision-making through data integration and predictive analytics. Distribution management focuses on the efficient planning, execution, and monitoring of product flow from warehouses to end customers, optimizing inventory and delivery performance. Explore more to understand how these strategic approaches transform supply chain efficiency.

Why it is important

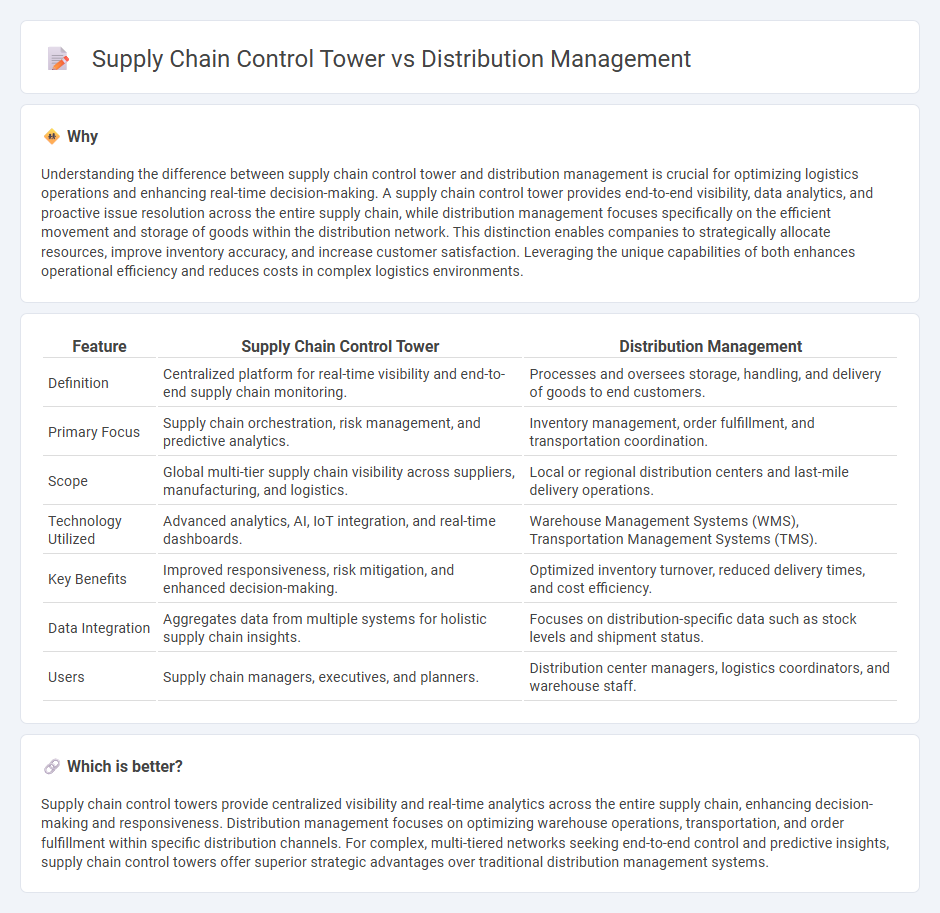

Understanding the difference between supply chain control tower and distribution management is crucial for optimizing logistics operations and enhancing real-time decision-making. A supply chain control tower provides end-to-end visibility, data analytics, and proactive issue resolution across the entire supply chain, while distribution management focuses specifically on the efficient movement and storage of goods within the distribution network. This distinction enables companies to strategically allocate resources, improve inventory accuracy, and increase customer satisfaction. Leveraging the unique capabilities of both enhances operational efficiency and reduces costs in complex logistics environments.

Comparison Table

| Feature | Supply Chain Control Tower | Distribution Management |

|---|---|---|

| Definition | Centralized platform for real-time visibility and end-to-end supply chain monitoring. | Processes and oversees storage, handling, and delivery of goods to end customers. |

| Primary Focus | Supply chain orchestration, risk management, and predictive analytics. | Inventory management, order fulfillment, and transportation coordination. |

| Scope | Global multi-tier supply chain visibility across suppliers, manufacturing, and logistics. | Local or regional distribution centers and last-mile delivery operations. |

| Technology Utilized | Advanced analytics, AI, IoT integration, and real-time dashboards. | Warehouse Management Systems (WMS), Transportation Management Systems (TMS). |

| Key Benefits | Improved responsiveness, risk mitigation, and enhanced decision-making. | Optimized inventory turnover, reduced delivery times, and cost efficiency. |

| Data Integration | Aggregates data from multiple systems for holistic supply chain insights. | Focuses on distribution-specific data such as stock levels and shipment status. |

| Users | Supply chain managers, executives, and planners. | Distribution center managers, logistics coordinators, and warehouse staff. |

Which is better?

Supply chain control towers provide centralized visibility and real-time analytics across the entire supply chain, enhancing decision-making and responsiveness. Distribution management focuses on optimizing warehouse operations, transportation, and order fulfillment within specific distribution channels. For complex, multi-tiered networks seeking end-to-end control and predictive insights, supply chain control towers offer superior strategic advantages over traditional distribution management systems.

Connection

A supply chain control tower provides real-time visibility and centralized monitoring of logistics operations, enabling efficient distribution management. By leveraging advanced analytics and data integration, it optimizes inventory levels, shipment routes, and delivery schedules across multiple distribution centers. This connectivity enhances decision-making, reduces lead times, and improves overall supply chain responsiveness.

Key Terms

**Distribution Management:**

Distribution management oversees the efficient movement of goods from warehouses to end customers, emphasizing inventory control, order fulfillment, and transportation logistics. It ensures timely deliveries, cost optimization, and real-time tracking within the distribution network. Explore how advanced distribution management systems can enhance operational efficiency and customer satisfaction.

Inventory Planning

Distribution management focuses on overseeing the movement, storage, and delivery of goods to ensure timely order fulfillment and optimal inventory levels. A supply chain control tower provides centralized, real-time visibility and data integration across multiple stages, enabling proactive inventory planning and risk mitigation. Explore how leveraging a supply chain control tower can enhance inventory planning beyond traditional distribution management.

Order Fulfillment

Distribution management focuses on optimizing warehousing, inventory control, and transportation to ensure timely order fulfillment across various channels. Supply chain control towers provide real-time visibility and centralized data analytics to monitor and manage end-to-end order processing, enhancing responsiveness and decision-making. Explore in-depth how integrating both approaches can revolutionize order fulfillment efficiency.

Source and External Links

Distribution Management Explained: Streamlining Supply Chains - Distribution management involves overseeing the movement of goods from suppliers to the final customer, facing challenges like supply chain disruptions, demand fluctuations, coordination, timely delivery, cost management, and returns, and it employs strategies such as mass, selective, and exclusive distribution methods based on business goals.

Distribution Management: Definition, Advantages & Strategies - Distribution management supervises goods flow through the supply chain and is influenced by factors like perishability, buyer habits, product forecasting, and trucking logistics, using mass, selective, or exclusive strategies, and integrates various management systems like CRM, WMS, and TMS.

Distribution Management - Overview, Channels, Factors - It is the supply chain function focusing on delivering goods timely and efficiently to end-users, optimizing shipping especially for perishables, and adjusting to demand variations and shipping efficiencies like truckload consolidation.

dowidth.com

dowidth.com