Cold chain visibility leverages real-time tracking technologies such as IoT sensors and GPS to monitor temperature and location throughout the supply chain, ensuring transparency and timely interventions. Cold chain integrity focuses on maintaining optimal environmental conditions and preventing temperature excursions during storage and transport to preserve product quality and safety. Explore the key differences and benefits of both approaches to optimize your cold chain logistics.

Why it is important

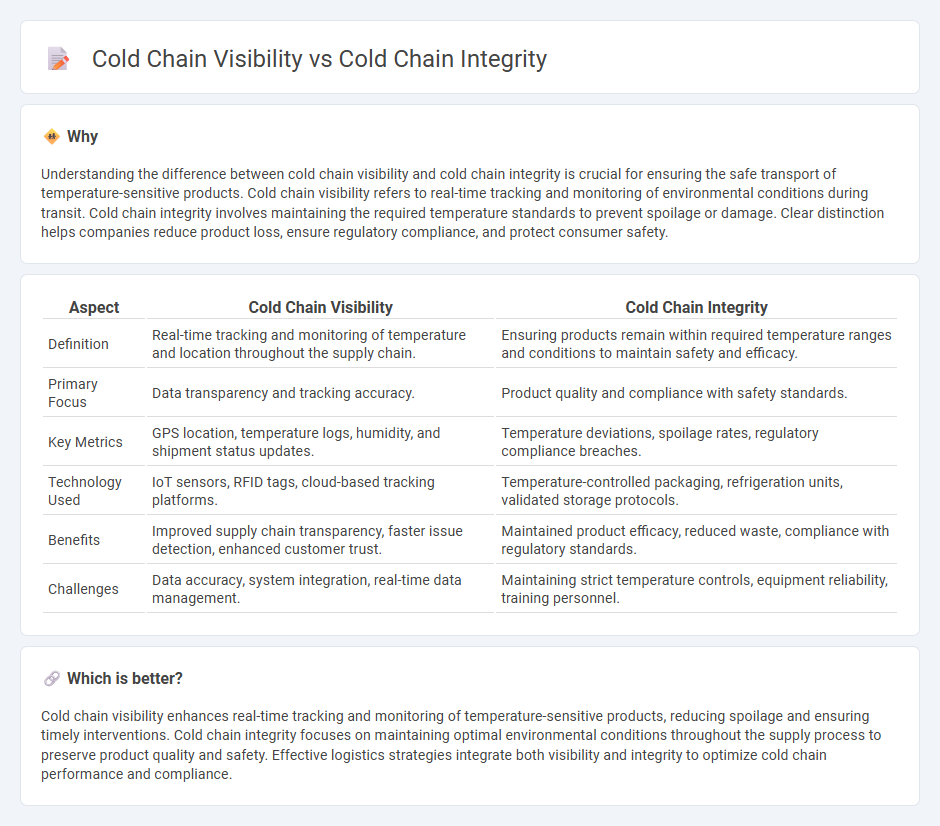

Understanding the difference between cold chain visibility and cold chain integrity is crucial for ensuring the safe transport of temperature-sensitive products. Cold chain visibility refers to real-time tracking and monitoring of environmental conditions during transit. Cold chain integrity involves maintaining the required temperature standards to prevent spoilage or damage. Clear distinction helps companies reduce product loss, ensure regulatory compliance, and protect consumer safety.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Integrity |

|---|---|---|

| Definition | Real-time tracking and monitoring of temperature and location throughout the supply chain. | Ensuring products remain within required temperature ranges and conditions to maintain safety and efficacy. |

| Primary Focus | Data transparency and tracking accuracy. | Product quality and compliance with safety standards. |

| Key Metrics | GPS location, temperature logs, humidity, and shipment status updates. | Temperature deviations, spoilage rates, regulatory compliance breaches. |

| Technology Used | IoT sensors, RFID tags, cloud-based tracking platforms. | Temperature-controlled packaging, refrigeration units, validated storage protocols. |

| Benefits | Improved supply chain transparency, faster issue detection, enhanced customer trust. | Maintained product efficacy, reduced waste, compliance with regulatory standards. |

| Challenges | Data accuracy, system integration, real-time data management. | Maintaining strict temperature controls, equipment reliability, training personnel. |

Which is better?

Cold chain visibility enhances real-time tracking and monitoring of temperature-sensitive products, reducing spoilage and ensuring timely interventions. Cold chain integrity focuses on maintaining optimal environmental conditions throughout the supply process to preserve product quality and safety. Effective logistics strategies integrate both visibility and integrity to optimize cold chain performance and compliance.

Connection

Cold chain visibility ensures real-time tracking of temperature-sensitive goods, enabling immediate detection of deviations that could compromise product quality. Maintaining cold chain integrity relies on consistent monitoring and timely interventions facilitated by this visibility, preventing spoilage and ensuring regulatory compliance. The integration of IoT sensors and data analytics strengthens both aspects by providing precise environmental control and actionable insights throughout the logistics process.

Key Terms

**Cold Chain Integrity:**

Cold chain integrity ensures that temperature-sensitive products are consistently maintained within prescribed environmental conditions throughout the supply chain, preventing spoilage and ensuring regulatory compliance. It involves real-time monitoring, secure packaging, and validated transport methods to guarantee product efficacy, especially for pharmaceuticals and perishable food items. Explore more to understand how maintaining cold chain integrity safeguards product quality and consumer safety.

Temperature Control

Cold chain integrity ensures that temperature-sensitive products are consistently maintained within required temperature ranges throughout the supply chain, preventing spoilage and ensuring product safety. Cold chain visibility provides real-time monitoring and data analytics on temperature conditions, enabling proactive interventions and traceability during transportation and storage. Explore advanced temperature control solutions to enhance both cold chain integrity and visibility for optimized supply chain performance.

Product Quality

Cold chain integrity ensures product quality by maintaining strict temperature control and preventing spoilage or degradation during storage and transportation. Cold chain visibility enhances this process by providing real-time tracking and monitoring of temperature data, enabling proactive response to deviations. Explore how integrating both aspects can safeguard product quality for perishable goods.

Source and External Links

Challenges in Maintaining Cold Chain Integrity for Food Transportation - Cold chain integrity involves maintaining precise temperature control across all stages of food transport to safeguard quality and safety, requiring robust monitoring, regulatory compliance, and skilled handling to prevent degradation and financial loss.

How to Maintain End-to-End Cold Chain System Integrity - Achieving end-to-end cold chain integrity demands collaboration, transparency, advanced technology, and processes such as precooling inventory to prevent temperature deviations and ensure product safety and quality for perishable goods.

Cold Chain Integrity Maintenance: Key Steps for Success - Maintaining cold chain integrity hinges on strict temperature control, continuous data monitoring secured by backup protocols, and integrating advanced tracking technologies to mitigate risks during transport and transitions between modes.

dowidth.com

dowidth.com