Pick and pack involves selecting products from inventory and packaging them for shipment, optimizing warehouse efficiency and order accuracy. Last mile delivery focuses on transporting goods from distribution centers directly to the customer's doorstep, emphasizing speed, reliability, and customer satisfaction. Explore how these critical logistics processes shape the supply chain and impact your business success.

Why it is important

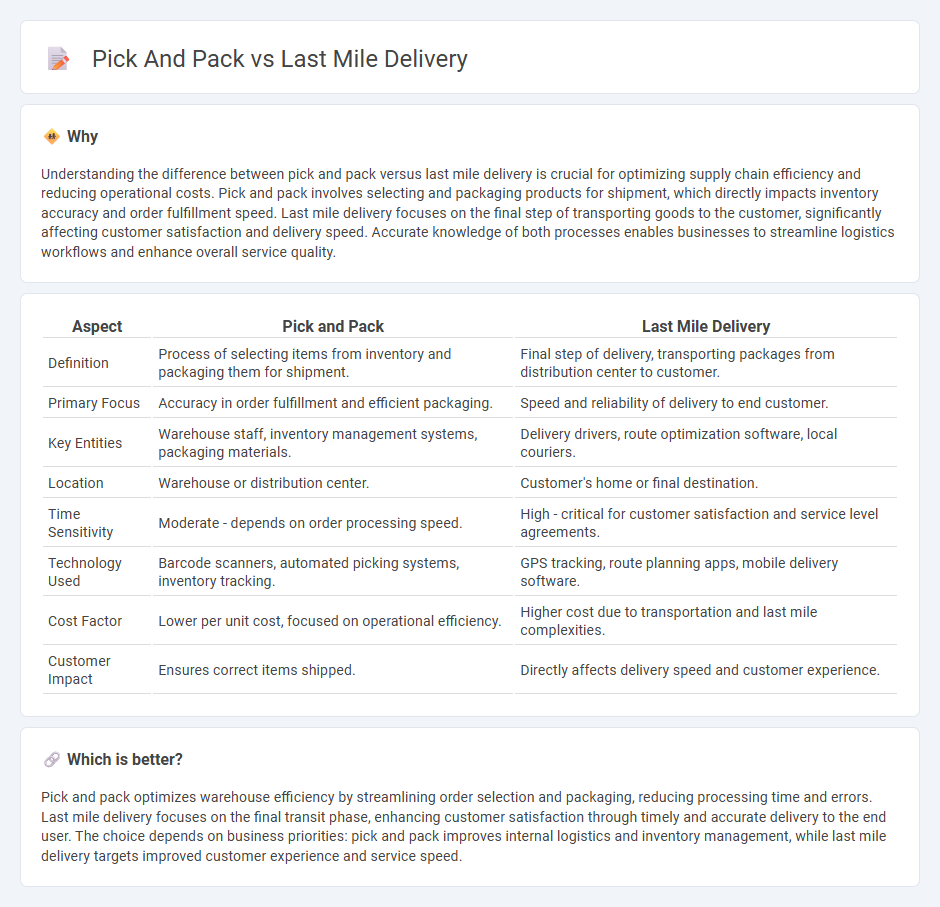

Understanding the difference between pick and pack versus last mile delivery is crucial for optimizing supply chain efficiency and reducing operational costs. Pick and pack involves selecting and packaging products for shipment, which directly impacts inventory accuracy and order fulfillment speed. Last mile delivery focuses on the final step of transporting goods to the customer, significantly affecting customer satisfaction and delivery speed. Accurate knowledge of both processes enables businesses to streamline logistics workflows and enhance overall service quality.

Comparison Table

| Aspect | Pick and Pack | Last Mile Delivery |

|---|---|---|

| Definition | Process of selecting items from inventory and packaging them for shipment. | Final step of delivery, transporting packages from distribution center to customer. |

| Primary Focus | Accuracy in order fulfillment and efficient packaging. | Speed and reliability of delivery to end customer. |

| Key Entities | Warehouse staff, inventory management systems, packaging materials. | Delivery drivers, route optimization software, local couriers. |

| Location | Warehouse or distribution center. | Customer's home or final destination. |

| Time Sensitivity | Moderate - depends on order processing speed. | High - critical for customer satisfaction and service level agreements. |

| Technology Used | Barcode scanners, automated picking systems, inventory tracking. | GPS tracking, route planning apps, mobile delivery software. |

| Cost Factor | Lower per unit cost, focused on operational efficiency. | Higher cost due to transportation and last mile complexities. |

| Customer Impact | Ensures correct items shipped. | Directly affects delivery speed and customer experience. |

Which is better?

Pick and pack optimizes warehouse efficiency by streamlining order selection and packaging, reducing processing time and errors. Last mile delivery focuses on the final transit phase, enhancing customer satisfaction through timely and accurate delivery to the end user. The choice depends on business priorities: pick and pack improves internal logistics and inventory management, while last mile delivery targets improved customer experience and service speed.

Connection

Efficient pick and pack operations directly impact last mile delivery by ensuring accurate order fulfillment and reducing processing time, which enhances customer satisfaction. Streamlined synchronization between warehouse picking systems and last mile distribution logistics minimizes errors and optimizes route planning for timely deliveries. Integrating inventory management with real-time tracking further strengthens the connection between pick and pack processes and final delivery performance.

Key Terms

**Last Mile Delivery:**

Last mile delivery encompasses the final step of the shipping process where goods are transported from a distribution center directly to the customer's location, emphasizing speed, accuracy, and real-time tracking. This stage is critical in e-commerce logistics as it directly impacts customer satisfaction and operational costs, with innovative solutions like route optimization and delivery drones improving efficiency. Explore more about last mile delivery innovations and their influence on modern supply chains.

Route Optimization

Last mile delivery focuses on optimizing routes to ensure timely, cost-effective shipment of goods from distribution centers directly to customers, leveraging GPS and real-time traffic data for enhanced accuracy. Pick and pack operations emphasize efficient product selection and packaging within warehouses, but route optimization in this context primarily pertains to internal workflow and batch processing rather than external delivery paths. To explore how route optimization transforms both last mile delivery and pick and pack processes, discover advanced logistics strategies and technologies driving supply chain efficiency.

Proof of Delivery

Proof of Delivery (POD) plays a critical role in last mile delivery by verifying that the package reaches the customer's hands, ensuring accuracy and reducing disputes. Pick and pack processes emphasize order accuracy and packaging efficiency but do not typically include direct customer verification like POD. Explore how integrating advanced POD solutions can enhance transparency and trust in your delivery operations.

Source and External Links

Last mile delivery: solutions for your business - Last mile delivery is the final stage of moving goods from a local distribution center to the consumer, focusing on speed, affordability, and accuracy via various transport methods like vans, bikes, or drop-off points, with rising interest in new methods such as drones and robots for enhanced efficiency and customer satisfaction.

How it Works, Benefits, & How to Fulfill with Last-Mile Carriers - Last-mile delivery involves transportation from a fulfillment center to the final destination, usually a residence, with last-mile carriers responsible for quick, cost-effective delivery and offering tracking to improve customer experience while facing high delivery costs that companies manage by using technology and third-party logistics partners.

Last-mile delivery: What it is and why it matters for retailers - The last mile is the final phase of delivery from warehouse to customer, critical for satisfaction and business success, where fast, reliable service drives higher sales and operational efficiency through automation, digital tools, and strategies targeting same-day and expanded delivery access to remote areas.

dowidth.com

dowidth.com