Cold chain management focuses on preserving the quality and safety of temperature-sensitive products through controlled environments during transportation and storage. Supply chain visibility encompasses real-time tracking and data integration across all stages of the supply chain to enhance transparency, efficiency, and decision-making. Explore how combining cold chain management with supply chain visibility can optimize your logistics operations.

Why it is important

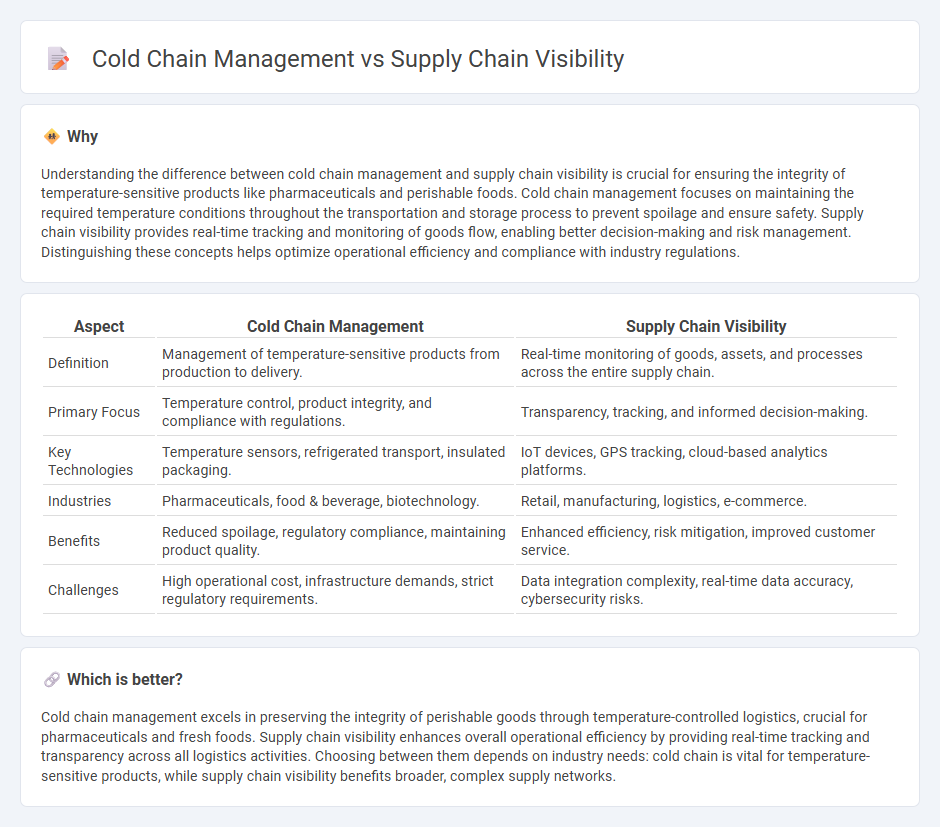

Understanding the difference between cold chain management and supply chain visibility is crucial for ensuring the integrity of temperature-sensitive products like pharmaceuticals and perishable foods. Cold chain management focuses on maintaining the required temperature conditions throughout the transportation and storage process to prevent spoilage and ensure safety. Supply chain visibility provides real-time tracking and monitoring of goods flow, enabling better decision-making and risk management. Distinguishing these concepts helps optimize operational efficiency and compliance with industry regulations.

Comparison Table

| Aspect | Cold Chain Management | Supply Chain Visibility |

|---|---|---|

| Definition | Management of temperature-sensitive products from production to delivery. | Real-time monitoring of goods, assets, and processes across the entire supply chain. |

| Primary Focus | Temperature control, product integrity, and compliance with regulations. | Transparency, tracking, and informed decision-making. |

| Key Technologies | Temperature sensors, refrigerated transport, insulated packaging. | IoT devices, GPS tracking, cloud-based analytics platforms. |

| Industries | Pharmaceuticals, food & beverage, biotechnology. | Retail, manufacturing, logistics, e-commerce. |

| Benefits | Reduced spoilage, regulatory compliance, maintaining product quality. | Enhanced efficiency, risk mitigation, improved customer service. |

| Challenges | High operational cost, infrastructure demands, strict regulatory requirements. | Data integration complexity, real-time data accuracy, cybersecurity risks. |

Which is better?

Cold chain management excels in preserving the integrity of perishable goods through temperature-controlled logistics, crucial for pharmaceuticals and fresh foods. Supply chain visibility enhances overall operational efficiency by providing real-time tracking and transparency across all logistics activities. Choosing between them depends on industry needs: cold chain is vital for temperature-sensitive products, while supply chain visibility benefits broader, complex supply networks.

Connection

Cold chain management relies heavily on supply chain visibility to ensure temperature-sensitive products remain within required conditions throughout transit. Real-time tracking and monitoring systems enable stakeholders to detect and respond to temperature fluctuations quickly, reducing spoilage and compliance risks. Enhanced visibility improves coordination among suppliers, transporters, and warehouses, leading to more efficient cold chain logistics operations.

Key Terms

**Supply Chain Visibility:**

Supply chain visibility involves real-time tracking and monitoring of goods, enabling companies to optimize inventory management, reduce delays, and enhance transparency across the entire supply network. It leverages technologies such as IoT sensors, GPS tracking, and data analytics to provide actionable insights for decision-making and risk mitigation. Discover how enhanced supply chain visibility can transform operational efficiency and customer satisfaction.

Real-time Tracking

Real-time tracking in supply chain visibility provides continuous monitoring of product location and condition, improving transparency and efficiency across all logistics stages. Cold chain management specifically leverages real-time data to maintain optimal temperature controls for perishable goods, preventing spoilage and ensuring regulatory compliance. Explore how integrating advanced tracking technologies enhances both supply chain visibility and cold chain reliability.

Data Integration

Supply chain visibility centers on real-time data integration across multiple stakeholders, enabling seamless tracking and improved decision-making throughout the logistics network. Cold chain management emphasizes precise temperature monitoring and data integration to ensure product quality and regulatory compliance in temperature-sensitive goods transport. Explore comprehensive strategies to optimize data integration for enhanced supply chain and cold chain performance.

Source and External Links

What is Supply Chain Visibility? Meaning and Definition - GEP - Supply chain visibility is the ability to view or track inventory as it moves through the supply chain in real time, enabling enterprises to optimize inventory, improve coordination, mitigate risk, and make data-driven decisions for enhanced efficiency and resilience.

What is Supply Chain Visibility? - Tibco - Supply chain visibility provides transparent and unified access to data tracking a product from raw materials to customers, reducing errors, improving production efficiency, and enhancing customer satisfaction.

What Is Supply Chain Visibility (SCV)? Definition & Examples - A highly visible supply chain offers transparency into suppliers, components, and products at every stage, allowing businesses to quickly identify and address issues while maintaining accurate inventory and improving relationships with partners.

dowidth.com

dowidth.com