Reshoring involves bringing manufacturing and production processes back to the company's home country to reduce dependency on distant suppliers and improve supply chain resilience. Supply chain diversification spreads sourcing and production across multiple countries to mitigate risks associated with geopolitical tensions, natural disasters, or market fluctuations. Explore the benefits and challenges of reshoring versus supply chain diversification to better understand their impact on global economic stability.

Why it is important

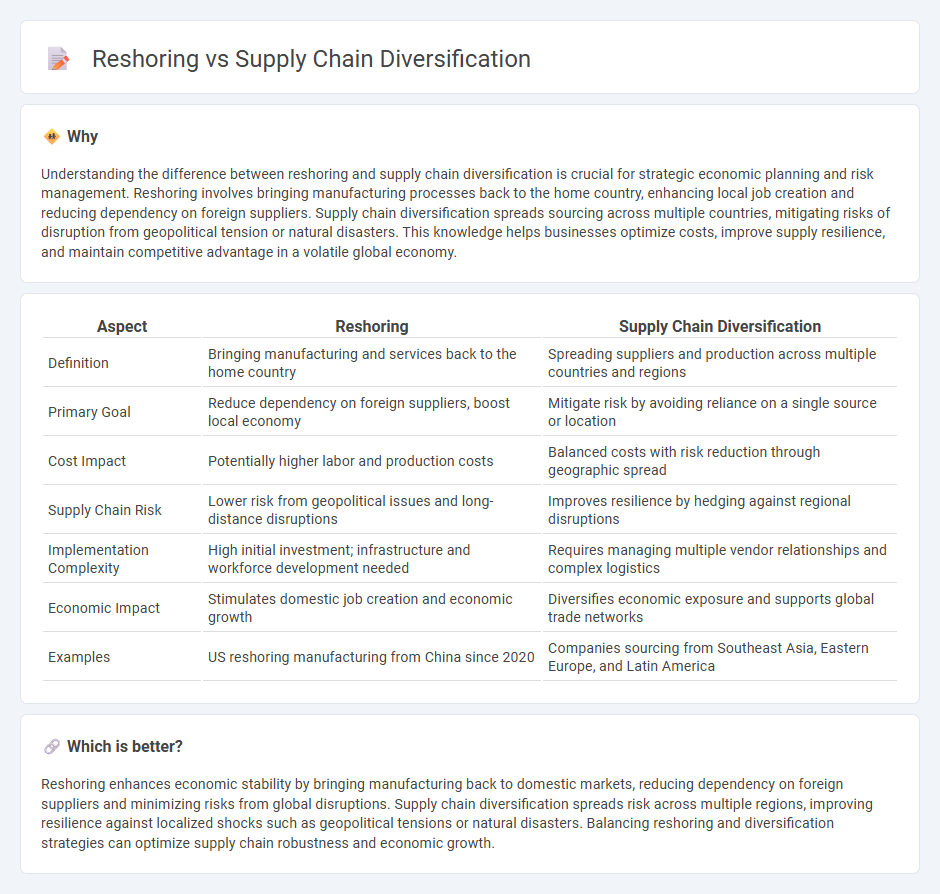

Understanding the difference between reshoring and supply chain diversification is crucial for strategic economic planning and risk management. Reshoring involves bringing manufacturing processes back to the home country, enhancing local job creation and reducing dependency on foreign suppliers. Supply chain diversification spreads sourcing across multiple countries, mitigating risks of disruption from geopolitical tension or natural disasters. This knowledge helps businesses optimize costs, improve supply resilience, and maintain competitive advantage in a volatile global economy.

Comparison Table

| Aspect | Reshoring | Supply Chain Diversification |

|---|---|---|

| Definition | Bringing manufacturing and services back to the home country | Spreading suppliers and production across multiple countries and regions |

| Primary Goal | Reduce dependency on foreign suppliers, boost local economy | Mitigate risk by avoiding reliance on a single source or location |

| Cost Impact | Potentially higher labor and production costs | Balanced costs with risk reduction through geographic spread |

| Supply Chain Risk | Lower risk from geopolitical issues and long-distance disruptions | Improves resilience by hedging against regional disruptions |

| Implementation Complexity | High initial investment; infrastructure and workforce development needed | Requires managing multiple vendor relationships and complex logistics |

| Economic Impact | Stimulates domestic job creation and economic growth | Diversifies economic exposure and supports global trade networks |

| Examples | US reshoring manufacturing from China since 2020 | Companies sourcing from Southeast Asia, Eastern Europe, and Latin America |

Which is better?

Reshoring enhances economic stability by bringing manufacturing back to domestic markets, reducing dependency on foreign suppliers and minimizing risks from global disruptions. Supply chain diversification spreads risk across multiple regions, improving resilience against localized shocks such as geopolitical tensions or natural disasters. Balancing reshoring and diversification strategies can optimize supply chain robustness and economic growth.

Connection

Reshoring enhances supply chain resilience by bringing manufacturing closer to home, reducing dependency on foreign suppliers and mitigating risks associated with geopolitical disruptions. Supply chain diversification complements reshoring by spreading sourcing across multiple regions, ensuring continuous production despite localized issues. Together, these strategies improve economic stability and promote sustainable growth in the global economy.

Key Terms

Globalization

Supply chain diversification involves expanding sourcing and manufacturing across multiple geographic regions to mitigate risks and leverage global expertise, while reshoring brings production closer to home to enhance control and reduce dependency on foreign suppliers. Globalization drives companies to balance cost-efficiency and resilience by integrating diverse international markets with localized operations. Explore more about how globalization shapes supply chain strategies to optimize performance and sustainability.

Risk Mitigation

Supply chain diversification spreads procurement across multiple geographic locations to reduce dependency on a single source, mitigating risks related to geopolitical instability, natural disasters, and supplier disruptions. Reshoring brings production closer to the home country, enhancing control, reducing lead times, and lowering transportation risks, but may increase costs. Explore detailed strategies to balance diversification and reshoring for optimal risk mitigation in your supply chain.

Domestic Production

Domestic production strengthens supply chain resilience by reducing reliance on international suppliers and minimizing disruptions from geopolitical tensions or global crises. Reshoring supports local economies through job creation and increased manufacturing capacity, while supply chain diversification spreads risk across multiple domestic and international sources to enhance flexibility. Explore detailed strategies and benefits of domestic production in supply chain optimization.

Source and External Links

The high impact of supply chain diversification - Delivered - Global - Supply chain diversification involves creating flexibility and redundancy with multiple suppliers and logistics options to minimize risk and increase agility, making supply chains more resilient amid global disruptions.

5 reasons to implement supply chain diversification - Maersk - Diversifying suppliers and production locations reduces risks from disruptions like natural disasters or geopolitical issues, building supply chain resilience and operational continuity.

Supply Chain Diversification and Resilience - A multi-country trade model shows that diversifying import sources can improve resilience against shocks at the expense of some efficiency, especially for goods exposed to higher risks in upstream supply chains.

dowidth.com

dowidth.com