The Shein effect revolutionizes fast fashion by leveraging data-driven demand forecasting and ultra-responsive supply chains to deliver new styles within days, contrasting sharply with traditional just-in-time production methods focused on minimizing inventory and reducing waste. This shift accelerates product turnover, creates hyper-responsive consumer experiences, and significantly alters supply chain dynamics worldwide. Explore how these models reshape global economies and retail strategies.

Why it is important

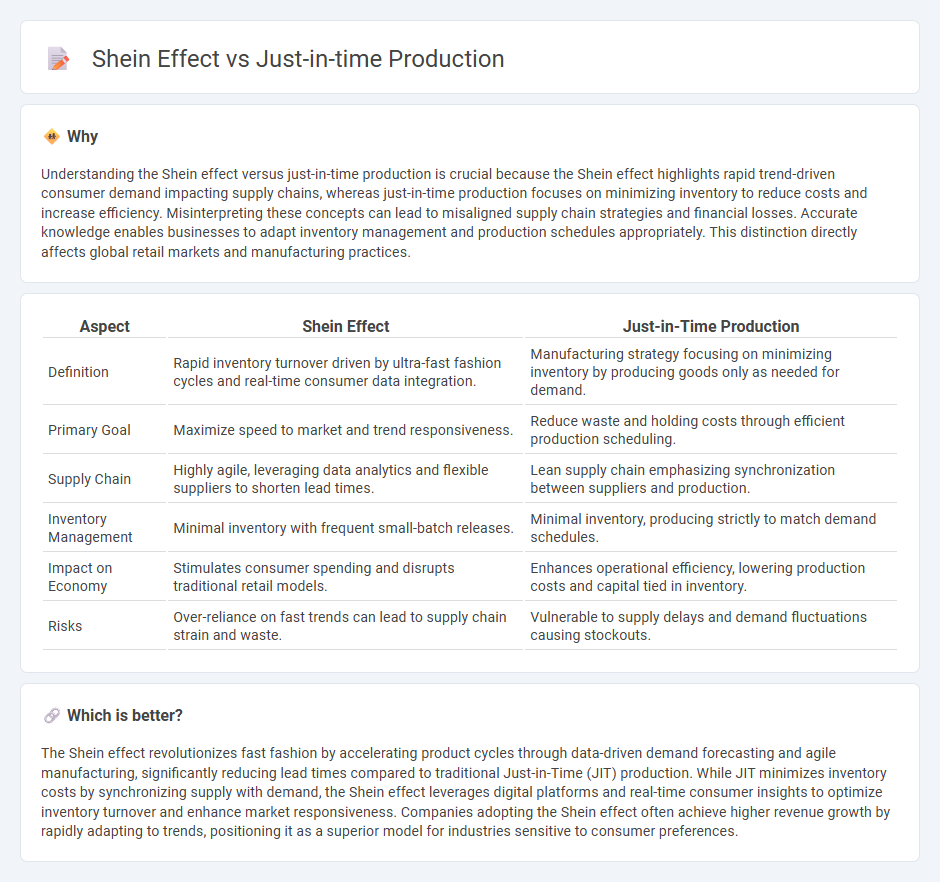

Understanding the Shein effect versus just-in-time production is crucial because the Shein effect highlights rapid trend-driven consumer demand impacting supply chains, whereas just-in-time production focuses on minimizing inventory to reduce costs and increase efficiency. Misinterpreting these concepts can lead to misaligned supply chain strategies and financial losses. Accurate knowledge enables businesses to adapt inventory management and production schedules appropriately. This distinction directly affects global retail markets and manufacturing practices.

Comparison Table

| Aspect | Shein Effect | Just-in-Time Production |

|---|---|---|

| Definition | Rapid inventory turnover driven by ultra-fast fashion cycles and real-time consumer data integration. | Manufacturing strategy focusing on minimizing inventory by producing goods only as needed for demand. |

| Primary Goal | Maximize speed to market and trend responsiveness. | Reduce waste and holding costs through efficient production scheduling. |

| Supply Chain | Highly agile, leveraging data analytics and flexible suppliers to shorten lead times. | Lean supply chain emphasizing synchronization between suppliers and production. |

| Inventory Management | Minimal inventory with frequent small-batch releases. | Minimal inventory, producing strictly to match demand schedules. |

| Impact on Economy | Stimulates consumer spending and disrupts traditional retail models. | Enhances operational efficiency, lowering production costs and capital tied in inventory. |

| Risks | Over-reliance on fast trends can lead to supply chain strain and waste. | Vulnerable to supply delays and demand fluctuations causing stockouts. |

Which is better?

The Shein effect revolutionizes fast fashion by accelerating product cycles through data-driven demand forecasting and agile manufacturing, significantly reducing lead times compared to traditional Just-in-Time (JIT) production. While JIT minimizes inventory costs by synchronizing supply with demand, the Shein effect leverages digital platforms and real-time consumer insights to optimize inventory turnover and enhance market responsiveness. Companies adopting the Shein effect often achieve higher revenue growth by rapidly adapting to trends, positioning it as a superior model for industries sensitive to consumer preferences.

Connection

Shein's rapid growth leverages just-in-time production to minimize inventory costs and respond swiftly to fashion trends, accelerating product turnover. This synergy reduces waste and enhances supply chain efficiency, enabling Shein to offer low prices and maintain competitive advantage. The integration of fast fashion with just-in-time strategies exemplifies a transformative shift in modern retail economics.

Key Terms

Inventory management

Just-in-time production minimizes inventory costs and reduces waste by aligning raw material orders closely with production schedules, enhancing efficiency in supply chain management. The Shein effect disrupts traditional inventory management by leveraging agile, data-driven demand forecasting to rapidly produce small batches of trendy apparel, thus minimizing unsold stock and maximizing responsiveness to market trends. Discover how innovative inventory strategies can optimize responsiveness and profitability in fast fashion and manufacturing sectors.

Fast fashion

Just-in-time production minimizes inventory costs by aligning manufacturing schedules closely with consumer demand, a method widely adopted in fast fashion to rapidly respond to trends. The Shein effect exemplifies hyper-fast fashion, leveraging ultra-quick design cycles and direct-to-consumer digital platforms to outpace traditional just-in-time models. Discover how these strategies reshape supply chains and sustainability in the fast fashion industry.

Supply chain agility

Just-in-time production minimizes inventory costs by synchronizing manufacturing with demand, enhancing supply chain agility through real-time responsiveness. The Shein effect accelerates fashion trends and shortens product life cycles, demanding ultra-flexible supply chains capable of rapid scaling and swift distribution. Explore how integrating just-in-time strategies with adaptive supply networks can revolutionize agility in fast fashion industries.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just-in-time (JIT) production is a manufacturing strategy focused on producing goods only as needed to increase efficiency, reduce waste, lower operational costs, improve supplier relationships, and enhance product quality through continuous monitoring and improvement.

Lean manufacturing - Wikipedia - JIT manufacturing aligns product output precisely with demand using methods like takt time, pull systems, and reducing lot sizes to eliminate defects, streamline processes, and enable flexible, efficient production flow.

Just-in-Time Production - Lean Enterprise Institute - JIT is a production system aiming to deliver just what is needed, when it is needed, founded on the Toyota Production System pillars of JIT and jidoka, focused on total waste elimination for quality, cost, and lead-time optimization.

dowidth.com

dowidth.com