De-risking focuses on minimizing exposure to geopolitical and supply chain disruptions by diversifying suppliers and markets, while reshoring involves relocating manufacturing and production processes back to the home country to enhance control and security. Both strategies aim to strengthen economic resilience and reduce dependency on foreign entities, influencing investment decisions and labor markets. Explore how these approaches impact global economic stability and business operations.

Why it is important

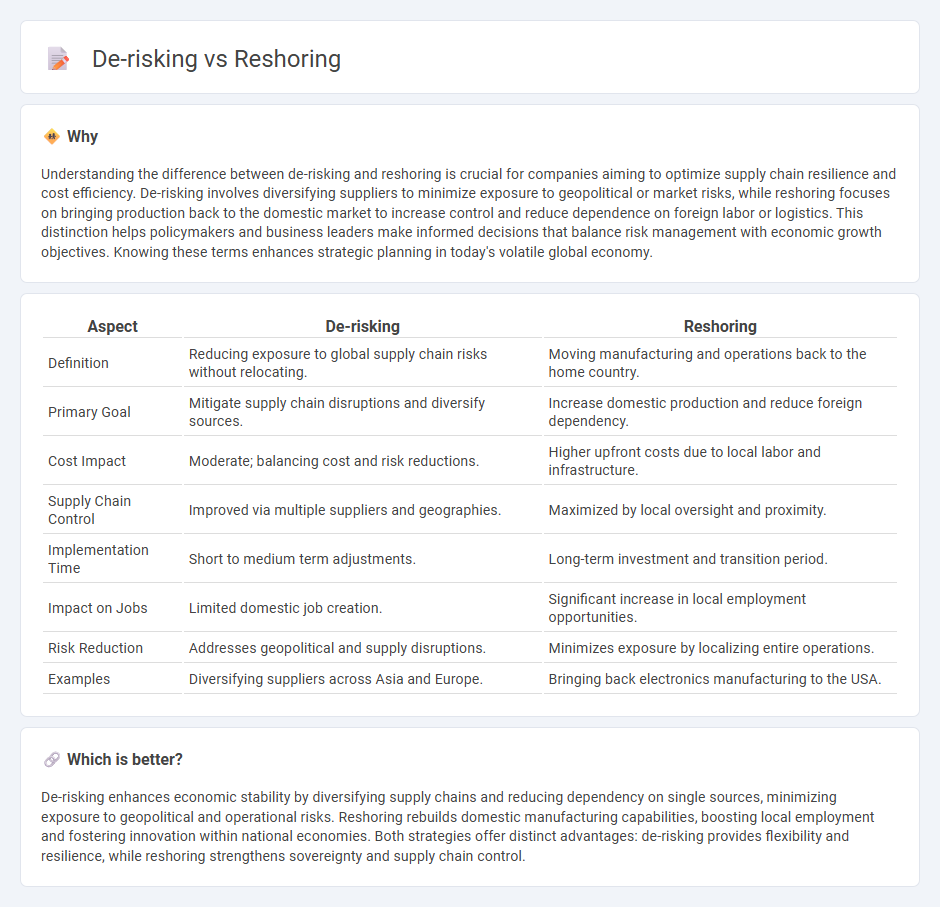

Understanding the difference between de-risking and reshoring is crucial for companies aiming to optimize supply chain resilience and cost efficiency. De-risking involves diversifying suppliers to minimize exposure to geopolitical or market risks, while reshoring focuses on bringing production back to the domestic market to increase control and reduce dependence on foreign labor or logistics. This distinction helps policymakers and business leaders make informed decisions that balance risk management with economic growth objectives. Knowing these terms enhances strategic planning in today's volatile global economy.

Comparison Table

| Aspect | De-risking | Reshoring |

|---|---|---|

| Definition | Reducing exposure to global supply chain risks without relocating. | Moving manufacturing and operations back to the home country. |

| Primary Goal | Mitigate supply chain disruptions and diversify sources. | Increase domestic production and reduce foreign dependency. |

| Cost Impact | Moderate; balancing cost and risk reductions. | Higher upfront costs due to local labor and infrastructure. |

| Supply Chain Control | Improved via multiple suppliers and geographies. | Maximized by local oversight and proximity. |

| Implementation Time | Short to medium term adjustments. | Long-term investment and transition period. |

| Impact on Jobs | Limited domestic job creation. | Significant increase in local employment opportunities. |

| Risk Reduction | Addresses geopolitical and supply disruptions. | Minimizes exposure by localizing entire operations. |

| Examples | Diversifying suppliers across Asia and Europe. | Bringing back electronics manufacturing to the USA. |

Which is better?

De-risking enhances economic stability by diversifying supply chains and reducing dependency on single sources, minimizing exposure to geopolitical and operational risks. Reshoring rebuilds domestic manufacturing capabilities, boosting local employment and fostering innovation within national economies. Both strategies offer distinct advantages: de-risking provides flexibility and resilience, while reshoring strengthens sovereignty and supply chain control.

Connection

De-risking strategies focus on minimizing supply chain vulnerabilities by diversifying suppliers and reducing dependency on high-risk regions, which directly supports reshoring initiatives that bring manufacturing and production back to domestic locations. Reshoring enhances economic stability by shortening supply chains, lowering transportation costs, and improving control over critical processes, thereby mitigating risks associated with geopolitical tensions and global disruptions. The integration of de-risking and reshoring strengthens national economic resilience and promotes sustainable growth through localized production ecosystems.

Key Terms

Supply Chain

Reshoring involves relocating supply chain operations back to the home country to reduce dependency on overseas suppliers, improve quality control, and shorten lead times. De-risking focuses on diversifying suppliers and sourcing strategies to minimize vulnerabilities such as geopolitical tensions, natural disasters, or global pandemics. Explore detailed strategies to optimize supply chain resilience and enhance operational efficiency.

Geopolitical Risk

Reshoring involves relocating manufacturing processes back to a company's home country to reduce dependency on foreign suppliers, mitigating geopolitical risks like trade wars and tariffs. De-risking, on the other hand, diversifies supply chains across multiple countries to avoid overreliance on any single geopolitical landscape, enhancing resilience against regional disruptions. Explore deeper insights on how reshoring and de-risking strategies can safeguard your business from evolving geopolitical challenges.

Production Costs

Reshoring involves relocating production closer to a company's home country to reduce costs linked to long supply chains, such as shipping and tariffs, while enhancing quality control. De-risking emphasizes diversifying supply sources and production sites to minimize vulnerabilities from geopolitical tensions, natural disasters, and supply interruptions, often leading to a more flexible but possibly higher-cost production strategy. Explore the nuances of reshoring and de-risking to optimize your production costs effectively.

Source and External Links

Reshoring - SCRG - Reshoring is the process of bringing manufacturing operations back to a company's home country from overseas, often to improve quality, lead time, and supply chain control.

What is Reshoring? Understanding Manufacturing Location Terms - Reshoring means relocating production from a foreign country back to the country where the company is headquartered or where its products are sold.

What is Reshoring? - Reshoring is the practice of returning manufacturing and services to the U.S. from abroad to strengthen the economy, create jobs, and reduce total product costs.

dowidth.com

dowidth.com