Modular construction offers factory-built, pre-fabricated sections that accelerate project timelines while ensuring quality control, contrasting with timber frame construction which relies on traditional on-site assembly using sustainable wooden frameworks. Timber frame structures provide natural insulation and aesthetic appeal, favored for energy efficiency and design flexibility in residential real estate. Explore the advantages and considerations of each method to determine the best fit for your real estate development needs.

Why it is important

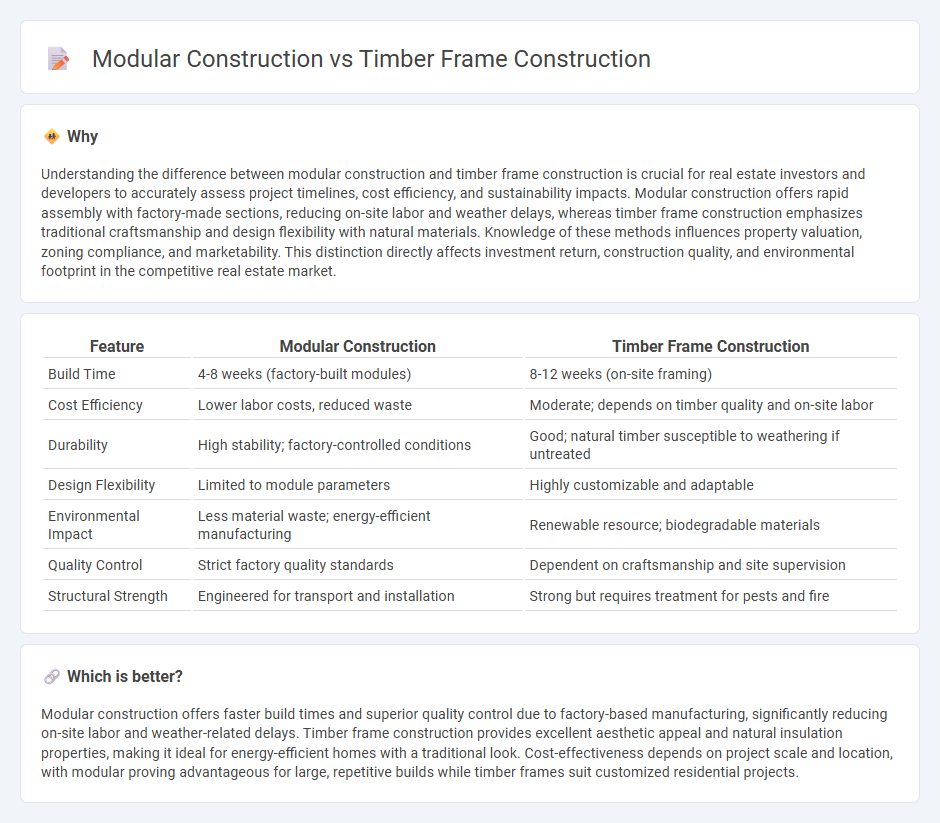

Understanding the difference between modular construction and timber frame construction is crucial for real estate investors and developers to accurately assess project timelines, cost efficiency, and sustainability impacts. Modular construction offers rapid assembly with factory-made sections, reducing on-site labor and weather delays, whereas timber frame construction emphasizes traditional craftsmanship and design flexibility with natural materials. Knowledge of these methods influences property valuation, zoning compliance, and marketability. This distinction directly affects investment return, construction quality, and environmental footprint in the competitive real estate market.

Comparison Table

| Feature | Modular Construction | Timber Frame Construction |

|---|---|---|

| Build Time | 4-8 weeks (factory-built modules) | 8-12 weeks (on-site framing) |

| Cost Efficiency | Lower labor costs, reduced waste | Moderate; depends on timber quality and on-site labor |

| Durability | High stability; factory-controlled conditions | Good; natural timber susceptible to weathering if untreated |

| Design Flexibility | Limited to module parameters | Highly customizable and adaptable |

| Environmental Impact | Less material waste; energy-efficient manufacturing | Renewable resource; biodegradable materials |

| Quality Control | Strict factory quality standards | Dependent on craftsmanship and site supervision |

| Structural Strength | Engineered for transport and installation | Strong but requires treatment for pests and fire |

Which is better?

Modular construction offers faster build times and superior quality control due to factory-based manufacturing, significantly reducing on-site labor and weather-related delays. Timber frame construction provides excellent aesthetic appeal and natural insulation properties, making it ideal for energy-efficient homes with a traditional look. Cost-effectiveness depends on project scale and location, with modular proving advantageous for large, repetitive builds while timber frames suit customized residential projects.

Connection

Modular construction and timber frame construction are connected through their emphasis on prefabrication techniques that accelerate building timelines and reduce onsite labor. Timber frame construction often serves as a primary structural system within modular units due to its strength-to-weight ratio and sustainability benefits. This integration supports efficient real estate development by combining the environmental advantages of timber with the cost-effectiveness and scalability of modular building methods.

Key Terms

Structural System

Timber frame construction relies on a skeleton of wooden posts and beams, providing flexibility in design and natural insulation qualities, while modular construction uses prefabricated sections engineered for rapid assembly and consistent quality control. The timber frame system allows for customization and adaptability on-site, whereas modular systems emphasize efficiency and reduced construction time through factory-built units. Discover how these structural systems impact durability, sustainability, and project timelines by exploring detailed comparisons.

Prefabrication

Timber frame construction involves assembling a skeletal frame made of wood components on-site, where prefabricated panels or beams are often prepared off-site to streamline the building process. Modular construction relies heavily on prefabrication by manufacturing complete room-sized modules in controlled factory settings, which are then transported and assembled on-site, significantly reducing construction time and waste. Explore the benefits and applications of each method to determine the ideal prefabrication approach for your project.

On-site Assembly

Timber frame construction involves assembling a skeletal framework of wooden beams and posts directly on-site, offering flexibility in design and customization while typically requiring longer construction periods. Modular construction, by contrast, consists of factory-fabricated sections transported to the site for rapid assembly, significantly reducing on-site labor and construction time. Explore the benefits and practical considerations of on-site assembly in both timber frame and modular construction methods to determine the best fit for your project.

Source and External Links

Timber Framing: What it is and What its not - This webpage provides an overview of timber framing, including its techniques, tools, and the use of mortise and tenon joints.

Basics: What is Timber Framing? - This page explains the basics of timber framing, highlighting its distinctive style and the use of heavy timbers joined by mortises and tenons.

Timber Framing 101 - Start Here - This webpage introduces the fundamentals of timber framing, including the use of heavy timbers and comparing it to other construction methods like conventional homes and log homes.

dowidth.com

dowidth.com