Pick to light systems enhance warehouse efficiency by using illuminated displays to guide operators quickly to the exact items for order fulfillment, reducing errors and boosting productivity in high-volume environments. Robotic picking systems automate the retrieval process entirely through advanced robotics and machine learning, offering scalability and precision ideal for complex or large-scale operations. Discover the benefits and best applications of each technology to optimize your logistics workflow.

Why it is important

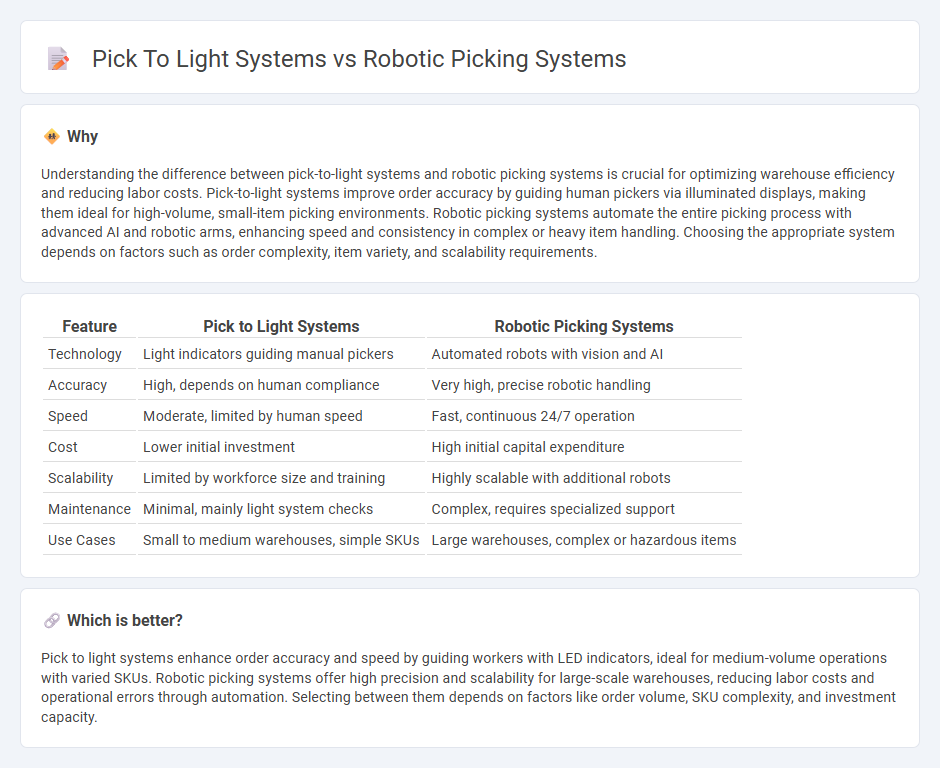

Understanding the difference between pick-to-light systems and robotic picking systems is crucial for optimizing warehouse efficiency and reducing labor costs. Pick-to-light systems improve order accuracy by guiding human pickers via illuminated displays, making them ideal for high-volume, small-item picking environments. Robotic picking systems automate the entire picking process with advanced AI and robotic arms, enhancing speed and consistency in complex or heavy item handling. Choosing the appropriate system depends on factors such as order complexity, item variety, and scalability requirements.

Comparison Table

| Feature | Pick to Light Systems | Robotic Picking Systems |

|---|---|---|

| Technology | Light indicators guiding manual pickers | Automated robots with vision and AI |

| Accuracy | High, depends on human compliance | Very high, precise robotic handling |

| Speed | Moderate, limited by human speed | Fast, continuous 24/7 operation |

| Cost | Lower initial investment | High initial capital expenditure |

| Scalability | Limited by workforce size and training | Highly scalable with additional robots |

| Maintenance | Minimal, mainly light system checks | Complex, requires specialized support |

| Use Cases | Small to medium warehouses, simple SKUs | Large warehouses, complex or hazardous items |

Which is better?

Pick to light systems enhance order accuracy and speed by guiding workers with LED indicators, ideal for medium-volume operations with varied SKUs. Robotic picking systems offer high precision and scalability for large-scale warehouses, reducing labor costs and operational errors through automation. Selecting between them depends on factors like order volume, SKU complexity, and investment capacity.

Connection

Pick to light systems enhance order accuracy by guiding warehouse workers with visual cues, while robotic picking systems automate item retrieval using advanced robotics and AI. Integration of these technologies streamlines warehouse operations by combining human decision-making precision with robotic speed and efficiency. This synergy reduces picking errors, accelerates order fulfillment, and optimizes inventory management in modern logistics environments.

Key Terms

Automation

Robotic picking systems enhance automation by utilizing advanced AI-driven vision and gripping technologies to handle diverse product types with high precision and speed, significantly reducing human error and labor costs. Pick to light systems boost efficiency in order fulfillment by guiding operators with illuminated indicators, optimizing picking accuracy primarily in low to medium volume warehouses. Explore the advantages and implementation strategies of both systems to elevate your warehouse automation.

Order accuracy

Robotic picking systems leverage advanced machine learning and vision algorithms to achieve order accuracy rates exceeding 99%, minimizing human error in complex item selection. Pick to light systems improve accuracy by guiding operators with illuminated indicators, typically reaching 95-98% order accuracy in high-volume environments. Explore how each technology can enhance your warehouse operations through detailed performance insights.

Throughput

Robotic picking systems achieve high throughput through precise automation and scalable handling of diverse SKU volumes, minimizing human error and operational delays. Pick to light systems enhance throughput by visually guiding operators for rapid, accurate item selection, optimizing pick speed in high-density order fulfillment environments. Explore the key efficiency metrics and operational comparisons to determine the ideal solution for your fulfillment needs.

Source and External Links

Picking Robot - Automated Warehouses - Mecalux - Mecalux offers a robotic picking system that uses AI vision software, a high-performance robotic arm, and a versatile gripping device to automate fast and precise order fulfillment with safety features for collaborative human-robot work.

Robotic Piece & Bin Picking | Bastian Solutions SmartPick - Bastian Solutions provides an AI-powered robotic bin picking system integrating vision technology and industrial robotics for fast, accurate piece picking that learns and improves over time, offering continuous 24/7 operation to reduce labor costs.

Robotic Order Picking Systems: What You Need To Know - Robotic picking systems include autonomous mobile robots (AMRs) that navigate warehouses to retrieve inventory with systems like inVia's Totes-to-Person approach, significantly boosting picking productivity by decoupling human-robot dependencies.

dowidth.com

dowidth.com