Pick and pack is a fulfillment method where individual orders are picked from inventory and packed for shipment, optimizing accuracy and customization for e-commerce businesses. Zone skipping streamlines delivery by consolidating packages destined for the same geographic area, reducing shipping costs and transit times through bulk transportation. Explore the advantages of each approach to determine the best logistics strategy for your supply chain.

Why it is important

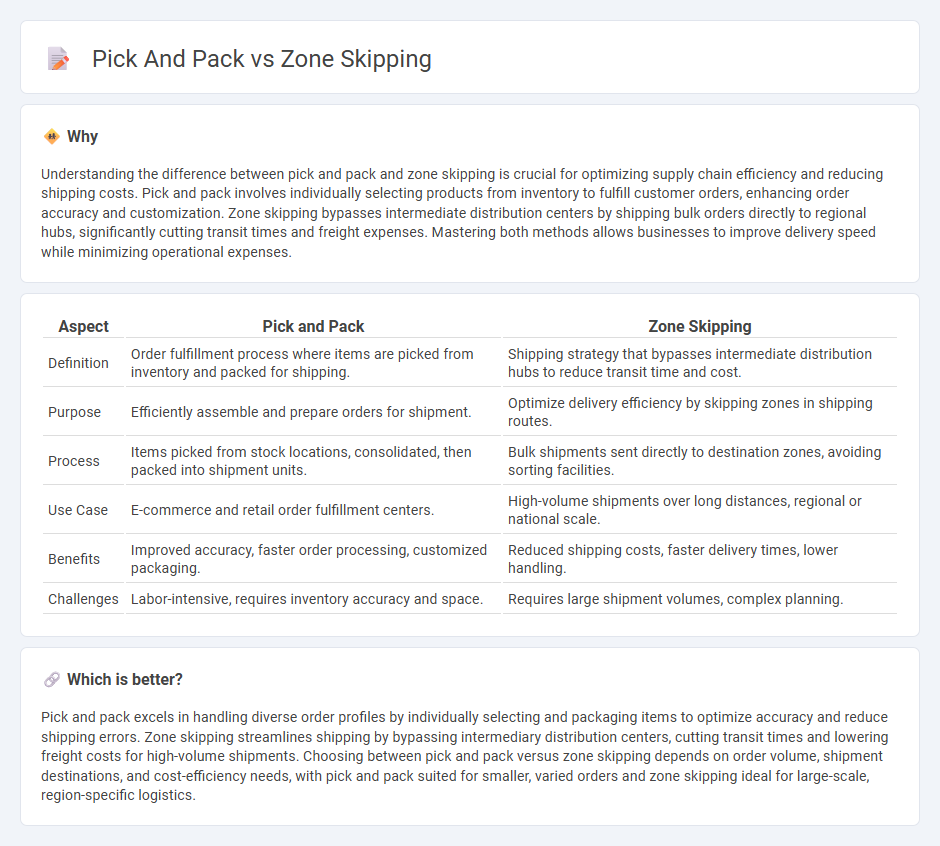

Understanding the difference between pick and pack and zone skipping is crucial for optimizing supply chain efficiency and reducing shipping costs. Pick and pack involves individually selecting products from inventory to fulfill customer orders, enhancing order accuracy and customization. Zone skipping bypasses intermediate distribution centers by shipping bulk orders directly to regional hubs, significantly cutting transit times and freight expenses. Mastering both methods allows businesses to improve delivery speed while minimizing operational expenses.

Comparison Table

| Aspect | Pick and Pack | Zone Skipping |

|---|---|---|

| Definition | Order fulfillment process where items are picked from inventory and packed for shipping. | Shipping strategy that bypasses intermediate distribution hubs to reduce transit time and cost. |

| Purpose | Efficiently assemble and prepare orders for shipment. | Optimize delivery efficiency by skipping zones in shipping routes. |

| Process | Items picked from stock locations, consolidated, then packed into shipment units. | Bulk shipments sent directly to destination zones, avoiding sorting facilities. |

| Use Case | E-commerce and retail order fulfillment centers. | High-volume shipments over long distances, regional or national scale. |

| Benefits | Improved accuracy, faster order processing, customized packaging. | Reduced shipping costs, faster delivery times, lower handling. |

| Challenges | Labor-intensive, requires inventory accuracy and space. | Requires large shipment volumes, complex planning. |

Which is better?

Pick and pack excels in handling diverse order profiles by individually selecting and packaging items to optimize accuracy and reduce shipping errors. Zone skipping streamlines shipping by bypassing intermediary distribution centers, cutting transit times and lowering freight costs for high-volume shipments. Choosing between pick and pack versus zone skipping depends on order volume, shipment destinations, and cost-efficiency needs, with pick and pack suited for smaller, varied orders and zone skipping ideal for large-scale, region-specific logistics.

Connection

Pick and pack processes in logistics streamline order fulfillment by efficiently selecting and packaging products for shipment. Zone skipping optimizes delivery by bypassing intermediate distribution centers, reducing transit time and shipping costs. Together, these strategies enhance supply chain efficiency by accelerating order processing and improving last-mile delivery speed.

Key Terms

Consolidation

Zone skipping streamlines shipping by aggregating packages in a centralized consolidation center, reducing transit time and costs through fewer handling points. Pick and pack involves selecting individual items per order and packaging them at the warehouse, often resulting in higher shipping expenses due to multiple handling steps. Explore how these methods impact logistics efficiency and cost optimization in warehouse operations.

Last-mile delivery

Zone skipping reduces last-mile delivery costs by consolidating shipments and bypassing intermediate hubs, optimizing transit times and lowering transportation expenses. Pick and pack enhances order accuracy and speed by individually processing and packaging items within a warehouse to meet specific customer requirements. Explore further to understand how these methods can transform your last-mile delivery efficiency and customer satisfaction.

Order fulfillment

Zone skipping reduces shipping costs and transit times by consolidating packages at a regional distribution center before final delivery, streamlining order fulfillment for high-volume shipments. Pick and pack focuses on efficiently selecting and packaging individual customer orders within a warehouse, optimizing accuracy and speed in order fulfillment processes. Explore more to understand which method best suits your business needs.

Source and External Links

What is Zone Skipping and Why is it Important in E-Commerce? - Zone skipping is a logistics strategy where consolidated shipments bypass intermediate zones or distribution centers to ship directly from the origin zone to the destination zone, reducing shipping costs and transit times by avoiding step-by-step processing and customs at intermediate points.

Zone skipping belongs in your shipping strategy - GoBolt - Zone skipping consolidates many individual parcels into one shipment sent directly to a target zone's sorting facility, cutting middle-mile logistics and lowering overall costs and transit time by paying a bulk shipping rate for the main haul plus lower local last-mile delivery charges.

Zone Skipping | CLS Multi-Carrier Shipping Software Glossary - Zone skipping is the practice of delivering large package volumes via truckload or less-than-truckload shipments to a parcel carrier hub near the final destination, skipping carrier zones to reduce costs based on mileage between origin and delivery zip codes, and expediting package movement to destination zones.

dowidth.com

dowidth.com