Cold chain traceability ensures the continuous monitoring of temperature-sensitive products, maintaining optimal conditions throughout storage and transportation to prevent spoilage. Shock and vibration monitoring focuses on detecting physical impacts and movement irregularities that can damage fragile goods during transit. Explore the distinct advantages and technologies behind cold chain traceability and shock and vibration monitoring to optimize your logistics operations.

Why it is important

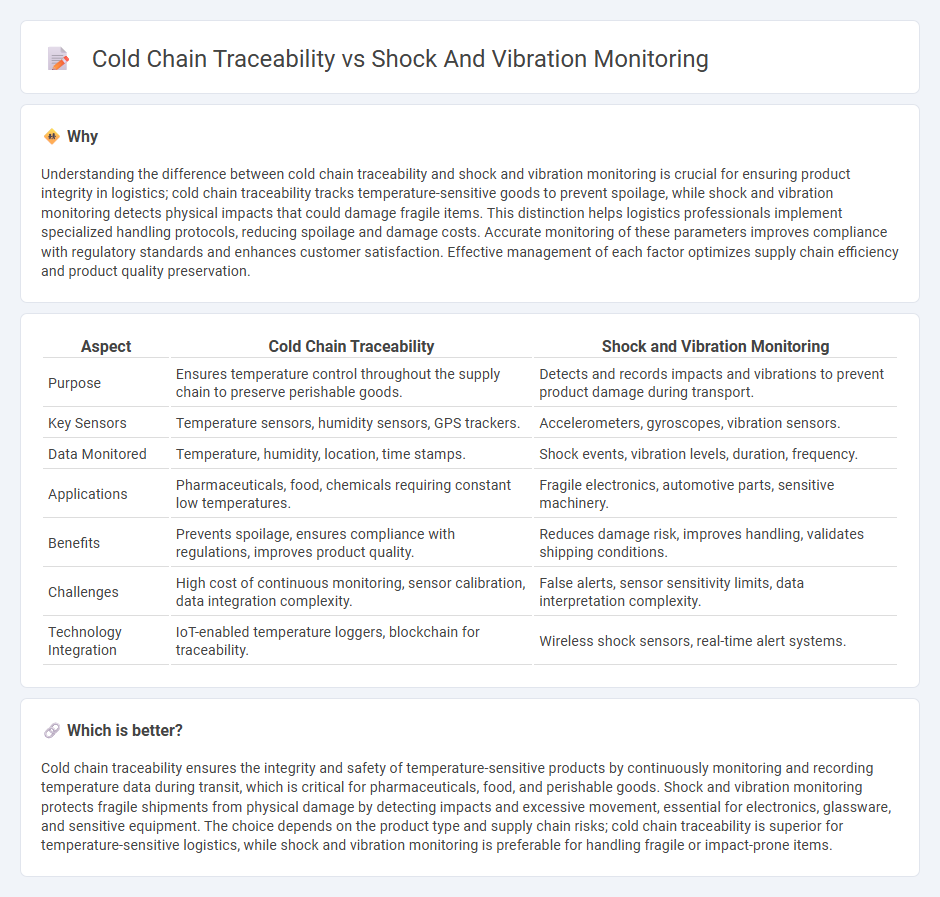

Understanding the difference between cold chain traceability and shock and vibration monitoring is crucial for ensuring product integrity in logistics; cold chain traceability tracks temperature-sensitive goods to prevent spoilage, while shock and vibration monitoring detects physical impacts that could damage fragile items. This distinction helps logistics professionals implement specialized handling protocols, reducing spoilage and damage costs. Accurate monitoring of these parameters improves compliance with regulatory standards and enhances customer satisfaction. Effective management of each factor optimizes supply chain efficiency and product quality preservation.

Comparison Table

| Aspect | Cold Chain Traceability | Shock and Vibration Monitoring |

|---|---|---|

| Purpose | Ensures temperature control throughout the supply chain to preserve perishable goods. | Detects and records impacts and vibrations to prevent product damage during transport. |

| Key Sensors | Temperature sensors, humidity sensors, GPS trackers. | Accelerometers, gyroscopes, vibration sensors. |

| Data Monitored | Temperature, humidity, location, time stamps. | Shock events, vibration levels, duration, frequency. |

| Applications | Pharmaceuticals, food, chemicals requiring constant low temperatures. | Fragile electronics, automotive parts, sensitive machinery. |

| Benefits | Prevents spoilage, ensures compliance with regulations, improves product quality. | Reduces damage risk, improves handling, validates shipping conditions. |

| Challenges | High cost of continuous monitoring, sensor calibration, data integration complexity. | False alerts, sensor sensitivity limits, data interpretation complexity. |

| Technology Integration | IoT-enabled temperature loggers, blockchain for traceability. | Wireless shock sensors, real-time alert systems. |

Which is better?

Cold chain traceability ensures the integrity and safety of temperature-sensitive products by continuously monitoring and recording temperature data during transit, which is critical for pharmaceuticals, food, and perishable goods. Shock and vibration monitoring protects fragile shipments from physical damage by detecting impacts and excessive movement, essential for electronics, glassware, and sensitive equipment. The choice depends on the product type and supply chain risks; cold chain traceability is superior for temperature-sensitive logistics, while shock and vibration monitoring is preferable for handling fragile or impact-prone items.

Connection

Cold chain traceability relies on precise shock and vibration monitoring to ensure the integrity of temperature-sensitive products during transit. Monitoring systems detect and record any physical impacts or vibrations that could compromise packaging or refrigeration, preventing spoilage or quality degradation. Integrating these technologies enhances the reliability of cold chain logistics by maintaining optimal conditions and providing real-time data for regulatory compliance.

Key Terms

**Shock and vibration monitoring:**

Shock and vibration monitoring employs advanced sensors and data loggers to detect impact forces and vibrations that can compromise the integrity of sensitive products during transportation. Real-time alerts and detailed analytics enable timely interventions to prevent damage and ensure compliance with industry standards. Discover how integrating shock and vibration monitoring enhances supply chain resilience and product safety.

Accelerometer

Accelerometers play a crucial role in both shock and vibration monitoring and cold chain traceability by accurately capturing real-time motion data to ensure product safety and quality. In shock and vibration monitoring, accelerometers detect sudden impacts and continuous vibrations to prevent equipment damage and ensure operational reliability. Explore how accelerometers enhance product protection and supply chain integrity by learning more about their specific applications in these fields.

Impact sensor

Impact sensors play a crucial role in shock and vibration monitoring by detecting sudden forces that may damage sensitive products during transit. Unlike cold chain traceability, which primarily tracks temperature conditions, impact sensors provide real-time data on mechanical stress, ensuring product integrity especially for fragile goods. Discover how integrating impact sensors can enhance your shipment monitoring solutions.

Source and External Links

Shock and vibration data logger - Wikipedia - Shock and vibration data loggers are autonomous measurement instruments that record shocks or vibrations over time using accelerometers and store the data digitally for later retrieval and analysis.

Protect valuable assets with shock and vibration monitoring. - SpotSee - Shock and vibration monitoring uses devices from simple impact indicators to sophisticated impact recorders to detect, measure, and record potential damaging shock and vibration events on high-value assets during storage and transit.

Data Loggers for Shock Vibration and Acceleration Measurement - MicroDAQ - Data loggers measure and record g-forces, tilt, orientation, temperature, and other environmental parameters with high sample rates, useful for transportation monitoring and research applications.

dowidth.com

dowidth.com