Micro-fulfillment centers optimize urban logistics by enabling faster delivery through automated, small-scale warehouses located near consumers, reducing last-mile costs and improving inventory accuracy. Retail backroom fulfillment relies on traditional store storage areas to pick and pack online orders, often facing constraints in space and efficiency compared to dedicated micro-fulfillment systems. Explore the advantages and challenges of these fulfillment strategies to enhance your supply chain performance.

Why it is important

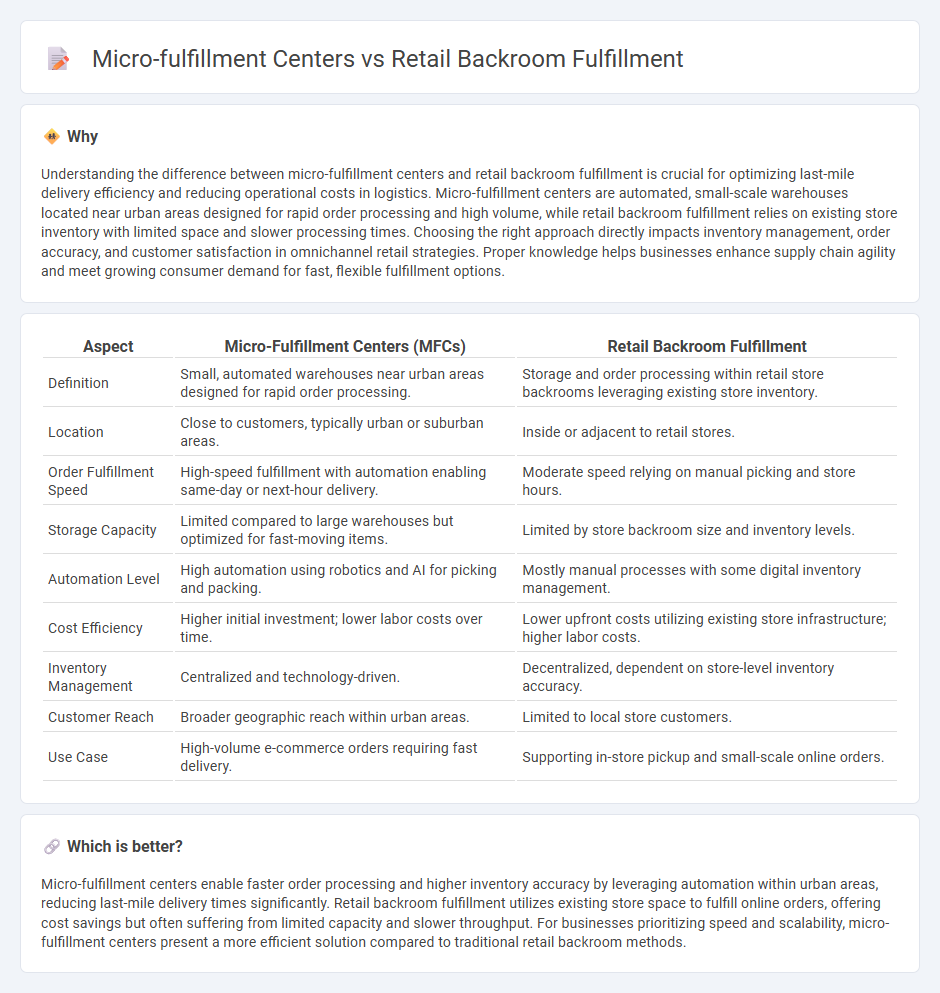

Understanding the difference between micro-fulfillment centers and retail backroom fulfillment is crucial for optimizing last-mile delivery efficiency and reducing operational costs in logistics. Micro-fulfillment centers are automated, small-scale warehouses located near urban areas designed for rapid order processing and high volume, while retail backroom fulfillment relies on existing store inventory with limited space and slower processing times. Choosing the right approach directly impacts inventory management, order accuracy, and customer satisfaction in omnichannel retail strategies. Proper knowledge helps businesses enhance supply chain agility and meet growing consumer demand for fast, flexible fulfillment options.

Comparison Table

| Aspect | Micro-Fulfillment Centers (MFCs) | Retail Backroom Fulfillment |

|---|---|---|

| Definition | Small, automated warehouses near urban areas designed for rapid order processing. | Storage and order processing within retail store backrooms leveraging existing store inventory. |

| Location | Close to customers, typically urban or suburban areas. | Inside or adjacent to retail stores. |

| Order Fulfillment Speed | High-speed fulfillment with automation enabling same-day or next-hour delivery. | Moderate speed relying on manual picking and store hours. |

| Storage Capacity | Limited compared to large warehouses but optimized for fast-moving items. | Limited by store backroom size and inventory levels. |

| Automation Level | High automation using robotics and AI for picking and packing. | Mostly manual processes with some digital inventory management. |

| Cost Efficiency | Higher initial investment; lower labor costs over time. | Lower upfront costs utilizing existing store infrastructure; higher labor costs. |

| Inventory Management | Centralized and technology-driven. | Decentralized, dependent on store-level inventory accuracy. |

| Customer Reach | Broader geographic reach within urban areas. | Limited to local store customers. |

| Use Case | High-volume e-commerce orders requiring fast delivery. | Supporting in-store pickup and small-scale online orders. |

Which is better?

Micro-fulfillment centers enable faster order processing and higher inventory accuracy by leveraging automation within urban areas, reducing last-mile delivery times significantly. Retail backroom fulfillment utilizes existing store space to fulfill online orders, offering cost savings but often suffering from limited capacity and slower throughput. For businesses prioritizing speed and scalability, micro-fulfillment centers present a more efficient solution compared to traditional retail backroom methods.

Connection

Micro-fulfillment centers and retail backroom fulfillment are interconnected through their shared goal of enhancing last-mile delivery efficiency and reducing order fulfillment time. Both solutions rely on advanced inventory management systems and automation technologies to streamline storage, picking, and packing processes. Integrating these fulfillment strategies enables retailers to optimize space utilization, improve order accuracy, and meet increasing consumer demand for rapid delivery.

Key Terms

Inventory Management

Retail backroom fulfillment relies on traditional storerooms within stores to manage inventory, often leading to slower restocking and limited space for accurate inventory tracking. Micro-fulfillment centers utilize advanced automation and AI-driven systems to optimize inventory accuracy, speed order processing, and minimize stockouts by situating fulfillment nodes closer to consumers. Explore how these innovative approaches transform inventory management and boost retail efficiency.

Order Picking

Retail backroom fulfillment relies heavily on manual order picking within store storage areas, limiting capacity and speed due to space constraints and labor intensity. Micro-fulfillment centers utilize automated systems and robotics to enhance order picking efficiency, allowing higher throughput and accuracy in smaller footprints near urban centers. Discover how these models impact supply chain agility and customer satisfaction.

Automation

Retail backroom fulfillment relies heavily on manual labor for order picking and inventory management, limiting speed and scalability, whereas micro-fulfillment centers integrate advanced automation technologies such as robotics and AI-driven systems to enhance efficiency and accuracy. Automation in micro-fulfillment centers reduces human error, accelerates order processing times, and optimizes space utilization, making it a superior option for retailers aiming to meet growing e-commerce demands. Explore how automation transforms retail logistics by diving deeper into the advantages of micro-fulfillment centers.

Source and External Links

Micro-Fulfillment Trends and Strategies - Dematic - Retail backroom fulfillment involves using micro-fulfillment centers, which are mini-automated warehouses located in the backrooms of stores to fulfill online orders locally, improving efficiency and consumer personalization.

Is ship from store fulfillment right for your retail business? - Ryder - Backroom fulfillment in retail stores faces challenges since stores are not designed as fulfillment centers, and limited backroom space can hinder efficient order processing and impact the in-store customer experience.

7 Ways to Boost In-Store Pick and Pack Efficiency - Fluent Commerce - Some retailers designate specific stores as fulfillment hubs with dedicated backroom inventory and staff for efficient online order pick and pack, blending warehouse-like operations with proximity to customers for faster delivery and cost savings.

dowidth.com

dowidth.com