Yard management focuses on the efficient control of vehicles and equipment movement within a logistics yard, optimizing inbound and outbound operations to reduce delays and improve asset utilization. Warehouse management involves overseeing storage, inventory accuracy, and order fulfillment processes inside the facility to enhance throughput and reduce operational costs. Explore how integrating yard and warehouse management systems can streamline logistics workflows and boost overall supply chain efficiency.

Why it is important

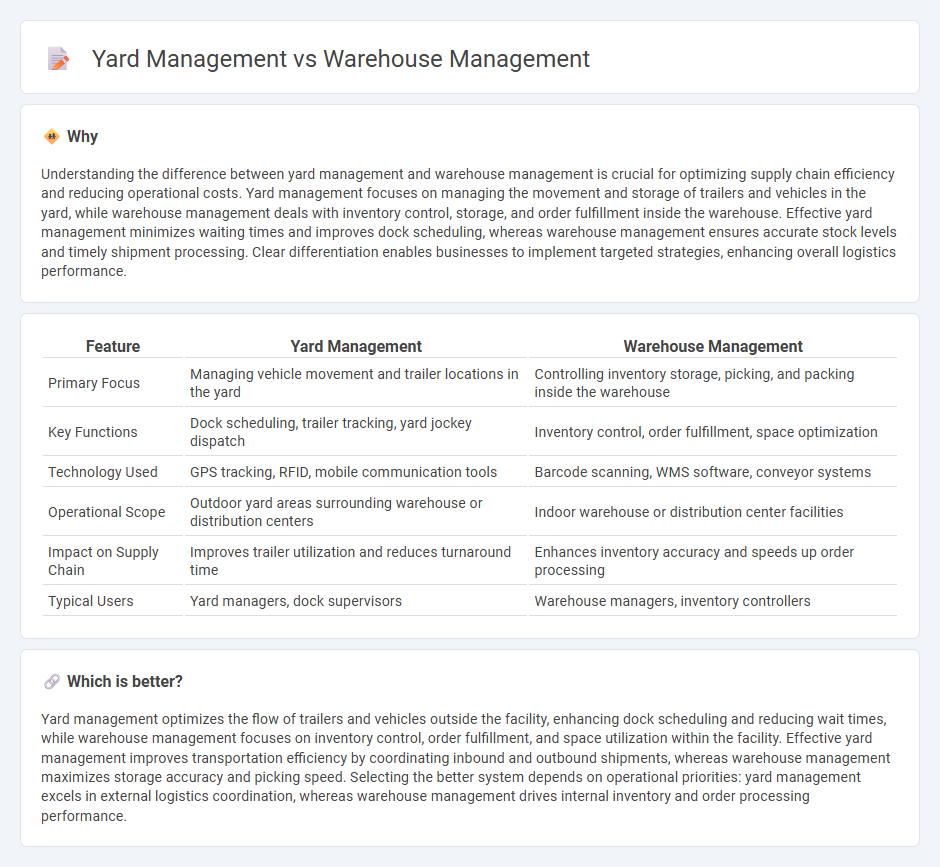

Understanding the difference between yard management and warehouse management is crucial for optimizing supply chain efficiency and reducing operational costs. Yard management focuses on managing the movement and storage of trailers and vehicles in the yard, while warehouse management deals with inventory control, storage, and order fulfillment inside the warehouse. Effective yard management minimizes waiting times and improves dock scheduling, whereas warehouse management ensures accurate stock levels and timely shipment processing. Clear differentiation enables businesses to implement targeted strategies, enhancing overall logistics performance.

Comparison Table

| Feature | Yard Management | Warehouse Management |

|---|---|---|

| Primary Focus | Managing vehicle movement and trailer locations in the yard | Controlling inventory storage, picking, and packing inside the warehouse |

| Key Functions | Dock scheduling, trailer tracking, yard jockey dispatch | Inventory control, order fulfillment, space optimization |

| Technology Used | GPS tracking, RFID, mobile communication tools | Barcode scanning, WMS software, conveyor systems |

| Operational Scope | Outdoor yard areas surrounding warehouse or distribution centers | Indoor warehouse or distribution center facilities |

| Impact on Supply Chain | Improves trailer utilization and reduces turnaround time | Enhances inventory accuracy and speeds up order processing |

| Typical Users | Yard managers, dock supervisors | Warehouse managers, inventory controllers |

Which is better?

Yard management optimizes the flow of trailers and vehicles outside the facility, enhancing dock scheduling and reducing wait times, while warehouse management focuses on inventory control, order fulfillment, and space utilization within the facility. Effective yard management improves transportation efficiency by coordinating inbound and outbound shipments, whereas warehouse management maximizes storage accuracy and picking speed. Selecting the better system depends on operational priorities: yard management excels in external logistics coordination, whereas warehouse management drives internal inventory and order processing performance.

Connection

Yard management and warehouse management are interconnected through the seamless coordination of inventory flow, optimizing loading and unloading processes, and ensuring accurate tracking of shipments within the supply chain. Efficient yard management reduces dwell time of trailers and vehicles, which directly impacts warehouse throughput and labor productivity. Real-time data integration between yard and warehouse systems enhances overall operational visibility, enabling faster decision-making and improved resource allocation.

Key Terms

**Warehouse Management:**

Warehouse management optimizes inventory control, order fulfillment, and storage efficiency using technologies like WMS (Warehouse Management System) to track goods and streamline processes. It enhances accuracy, reduces operational costs, and improves overall supply chain visibility by managing inbound and outbound logistics within the warehouse. Explore how advanced warehouse management solutions can transform your supply chain performance.

Inventory Control

Warehouse management centers on optimizing inventory control by tracking stock levels, locations, and movements within the facility to ensure accurate order fulfillment and minimize stockouts or overstock situations. Yard management complements this by coordinating the flow and placement of trailers and vehicles outside the warehouse, facilitating efficient loading, unloading, and transfer of inventory. Explore further to understand how integrating warehouse and yard management systems can enhance overall supply chain efficiency.

Order Fulfillment

Warehouse management optimizes inventory control, picking processes, and storage layout to accelerate order fulfillment, ensuring accurate and timely shipment preparation. Yard management coordinates the movement and staging of trucks and trailers outside the warehouse, facilitating smooth loading and unloading operations which directly impact order cycle times. Explore how integrating warehouse and yard management systems enhances overall order fulfillment efficiency.

Source and External Links

What is Warehouse Management? - This webpage discusses the principles and processes involved in managing warehouse operations effectively, including maintaining optimal stock levels and efficient transaction processing.

What is Warehouse Management? - This article outlines the core processes of warehouse management, such as receiving, put-away, storage, picking, packing, and shipping, while emphasizing the importance of optimizing these processes.

Warehouse Management: A Complete Guide - This guide provides an overview of effective warehouse management, focusing on process optimization, real-time performance analytics, and labor productivity to ensure efficient operations.

dowidth.com

dowidth.com