Predictive fleet maintenance leverages real-time data and advanced analytics to anticipate vehicle failures and schedule timely repairs, reducing downtime and operational costs. Route optimization employs algorithms and GPS technology to determine the most efficient delivery paths, minimizing fuel consumption and improving delivery speed. Discover how integrating these innovations can transform logistics efficiency and reliability.

Why it is important

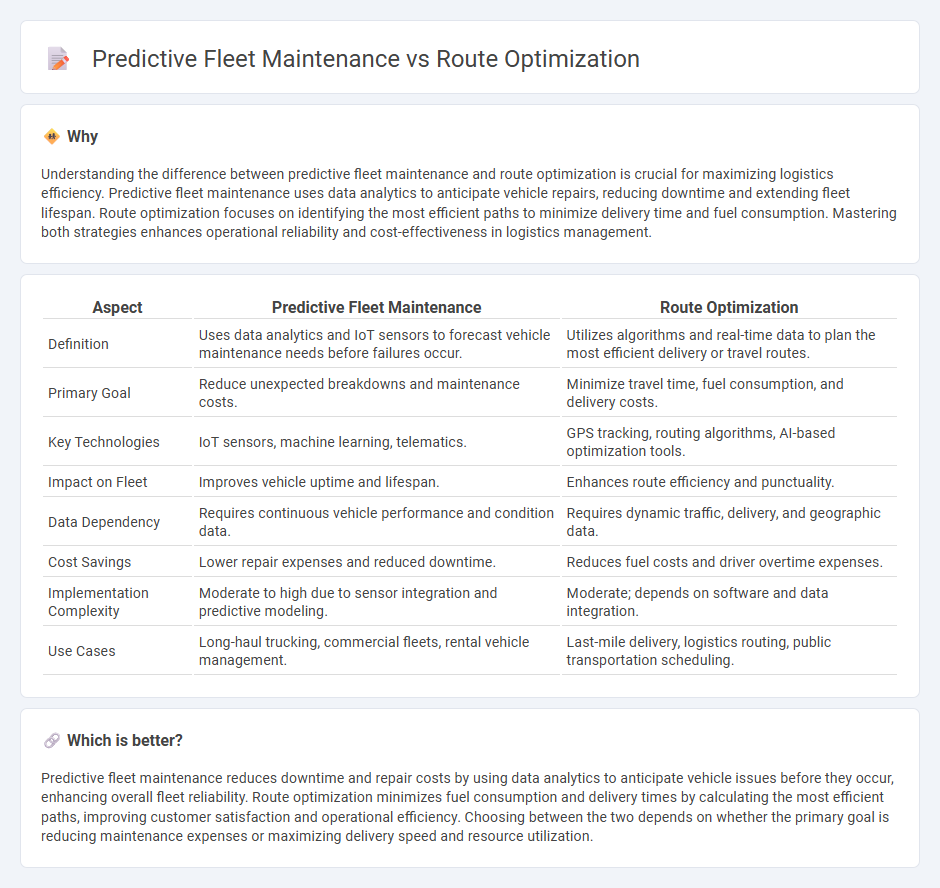

Understanding the difference between predictive fleet maintenance and route optimization is crucial for maximizing logistics efficiency. Predictive fleet maintenance uses data analytics to anticipate vehicle repairs, reducing downtime and extending fleet lifespan. Route optimization focuses on identifying the most efficient paths to minimize delivery time and fuel consumption. Mastering both strategies enhances operational reliability and cost-effectiveness in logistics management.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Route Optimization |

|---|---|---|

| Definition | Uses data analytics and IoT sensors to forecast vehicle maintenance needs before failures occur. | Utilizes algorithms and real-time data to plan the most efficient delivery or travel routes. |

| Primary Goal | Reduce unexpected breakdowns and maintenance costs. | Minimize travel time, fuel consumption, and delivery costs. |

| Key Technologies | IoT sensors, machine learning, telematics. | GPS tracking, routing algorithms, AI-based optimization tools. |

| Impact on Fleet | Improves vehicle uptime and lifespan. | Enhances route efficiency and punctuality. |

| Data Dependency | Requires continuous vehicle performance and condition data. | Requires dynamic traffic, delivery, and geographic data. |

| Cost Savings | Lower repair expenses and reduced downtime. | Reduces fuel costs and driver overtime expenses. |

| Implementation Complexity | Moderate to high due to sensor integration and predictive modeling. | Moderate; depends on software and data integration. |

| Use Cases | Long-haul trucking, commercial fleets, rental vehicle management. | Last-mile delivery, logistics routing, public transportation scheduling. |

Which is better?

Predictive fleet maintenance reduces downtime and repair costs by using data analytics to anticipate vehicle issues before they occur, enhancing overall fleet reliability. Route optimization minimizes fuel consumption and delivery times by calculating the most efficient paths, improving customer satisfaction and operational efficiency. Choosing between the two depends on whether the primary goal is reducing maintenance expenses or maximizing delivery speed and resource utilization.

Connection

Predictive fleet maintenance utilizes real-time sensor data and machine learning algorithms to forecast vehicle component failures, minimizing unexpected breakdowns and maximizing fleet uptime. Route optimization leverages advanced GPS data and traffic analytics to determine the most efficient paths, reducing fuel consumption and delivery times. Integrating predictive maintenance with route optimization ensures a seamless operation by aligning vehicle readiness with optimal routing, enhancing overall logistics efficiency and cost savings.

Key Terms

**Route Optimization:**

Route optimization leverages algorithms and real-time data to determine the most efficient paths for fleets, reducing fuel consumption and delivery times while enhancing customer satisfaction. This process integrates GPS tracking, traffic patterns, and vehicle load information to minimize operational costs and environmental impact. Explore how advanced route optimization technology can transform your logistics strategy.

Shortest Path Algorithm

The Shortest Path Algorithm plays a crucial role in route optimization by determining the most efficient routes for fleet vehicles, reducing travel time and fuel consumption. While predictive fleet maintenance focuses on forecasting vehicle issues to minimize downtime, route optimization directly enhances operational efficiency through strategic routing. Explore how integrating the Shortest Path Algorithm with predictive maintenance can transform fleet management.

Geocoding

Route optimization leverages geocoding to convert addresses into precise geographic coordinates, enabling efficient path planning and reduced travel times for fleet vehicles. Predictive fleet maintenance uses geocoding data to associate vehicle locations with maintenance schedules and service points, enhancing operational uptime. Discover how integrating geocoding enhances both route optimization and predictive maintenance strategies.

Source and External Links

Route Optimization Basics - Route optimization improves routes for better efficiency and cost-effectiveness by planning schedules in advance, balancing driver workloads, analyzing historical data, and adjusting routes in real time using software.

Ultimate Guide to Route Optimization - Route optimization involves importing addresses, defining constraints like delivery windows and vehicle capacity, then using software algorithms to generate and refine the shortest, most cost-effective routes.

What is Route Optimization? - Route optimization uses technology to evaluate delivery permutations and constraints to reduce fleet costs, improve customer service and save 5-15% in productivity and fuel by minimizing distance and optimizing resource use.

dowidth.com

dowidth.com