Drop shipping involves selling products directly from a supplier to the customer without holding inventory, reducing warehousing costs and minimizing lead times. Cross-docking streamlines supply chains by transferring goods directly from inbound to outbound transportation with minimal storage, optimizing delivery speed and efficiency. Explore the advantages and operational differences of drop shipping and cross-docking to enhance your logistics strategy.

Why it is important

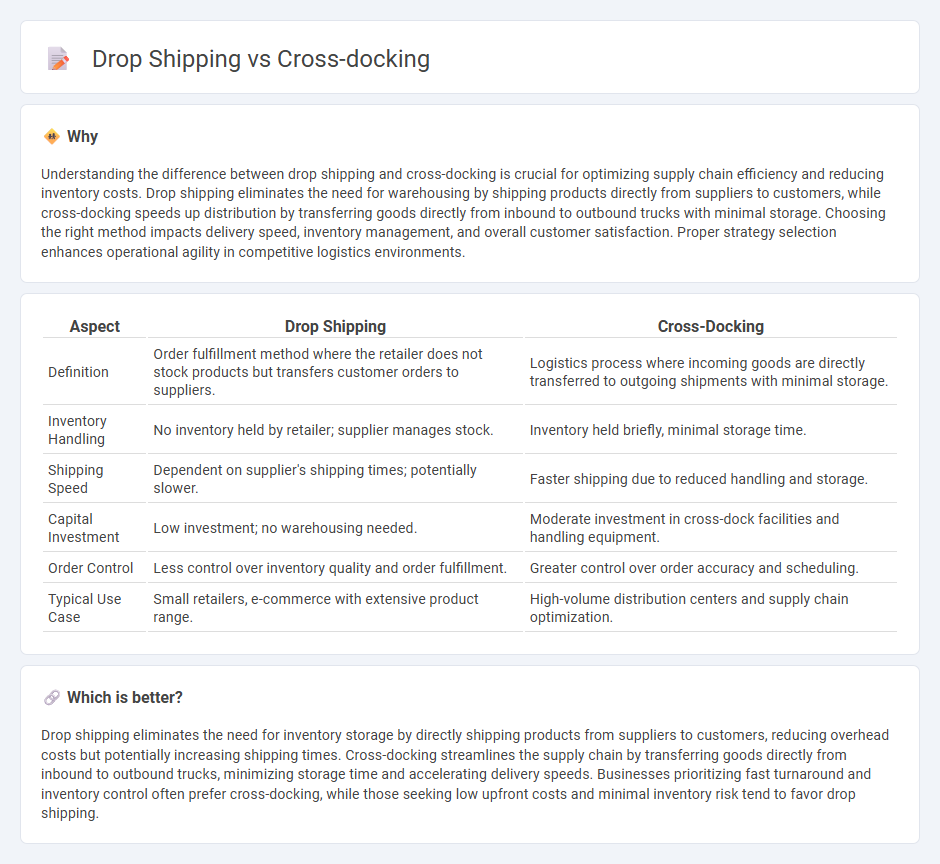

Understanding the difference between drop shipping and cross-docking is crucial for optimizing supply chain efficiency and reducing inventory costs. Drop shipping eliminates the need for warehousing by shipping products directly from suppliers to customers, while cross-docking speeds up distribution by transferring goods directly from inbound to outbound trucks with minimal storage. Choosing the right method impacts delivery speed, inventory management, and overall customer satisfaction. Proper strategy selection enhances operational agility in competitive logistics environments.

Comparison Table

| Aspect | Drop Shipping | Cross-Docking |

|---|---|---|

| Definition | Order fulfillment method where the retailer does not stock products but transfers customer orders to suppliers. | Logistics process where incoming goods are directly transferred to outgoing shipments with minimal storage. |

| Inventory Handling | No inventory held by retailer; supplier manages stock. | Inventory held briefly, minimal storage time. |

| Shipping Speed | Dependent on supplier's shipping times; potentially slower. | Faster shipping due to reduced handling and storage. |

| Capital Investment | Low investment; no warehousing needed. | Moderate investment in cross-dock facilities and handling equipment. |

| Order Control | Less control over inventory quality and order fulfillment. | Greater control over order accuracy and scheduling. |

| Typical Use Case | Small retailers, e-commerce with extensive product range. | High-volume distribution centers and supply chain optimization. |

Which is better?

Drop shipping eliminates the need for inventory storage by directly shipping products from suppliers to customers, reducing overhead costs but potentially increasing shipping times. Cross-docking streamlines the supply chain by transferring goods directly from inbound to outbound trucks, minimizing storage time and accelerating delivery speeds. Businesses prioritizing fast turnaround and inventory control often prefer cross-docking, while those seeking low upfront costs and minimal inventory risk tend to favor drop shipping.

Connection

Drop shipping and cross-docking both streamline logistics by minimizing inventory holding and accelerating product flow from suppliers to customers. Drop shipping eliminates the need for warehouses by shipping products directly from suppliers to consumers, while cross-docking involves the rapid transfer of goods from inbound to outbound transportation without storage. Together, these methods optimize supply chain efficiency, reduce handling costs, and improve delivery speed.

Key Terms

Inventory Holding

Cross-docking minimizes inventory holding by transferring products directly from inbound to outbound transportation with little to no storage time. Drop shipping eliminates inventory holding entirely as retailers do not stock products but rely on suppliers to ship directly to customers. Discover more about how these strategies impact supply chain efficiency and costs.

Fulfillment Speed

Cross-docking eliminates storage time by directly transferring goods from inbound to outbound transportation, significantly accelerating fulfillment speed. Drop shipping, while reducing inventory management burdens, relies on supplier processing times which can introduce delays. Explore more to understand which method optimizes your supply chain efficiency.

Supply Chain Ownership

Cross-docking streamlines supply chain ownership by minimizing inventory holding and transferring products directly from inbound to outbound shipments, enhancing control over logistics operations. Drop shipping shifts supply chain ownership to the supplier by eliminating the need for the retailer to hold inventory, focusing instead on order fulfillment and customer service. Explore how these supply chain models impact logistics efficiency and operational control in depth.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from inbound to outbound transportation modes with minimal storage, employing methods like continuous flow, consolidation of small shipments, and de-consolidation of large shipments.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a logistics technique that speeds delivery and reduces costs by unloading goods inbound and loading them directly onto outbound vehicles with minimal or no storage in between.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking is a process transferring goods from suppliers directly to customers or production with minimal storage, featuring types such as pre-distribution, post-distribution, continuous, consolidation, deconsolidation, and specialized forms for retail, manufacturing, and e-commerce.

dowidth.com

dowidth.com